Corporate News

Company News

- Aluminum veneer: the fashionable new darling of modern architecture

- Aluminum veneer customization, creating an exclusive personalized space

- Aluminum curtain wall: the fashionable coat of urban architecture

- Aluminum veneer: the 'invisible magician' of the construction industry

- Aluminum ceiling, the fashionable choice of modern architecture

Industry dynamics

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

- Aluminum honeycomb panel: the 'invisible hero' of the construction industry!

- What is the fire rating of aluminum veneer?

- Honeycomb aluminum plate: a lightweight choice, a fresh architectural style

- Customize aluminum veneer to make your space look brand new!

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What is the market demand for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the technological secret behind its lightweight design

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-26 20:35:09

- Click:0

Have you ever wondered why some electronic products are so lightweight? Honeycomb aluminum plate, this niche term, hides big technological secrets behind it!

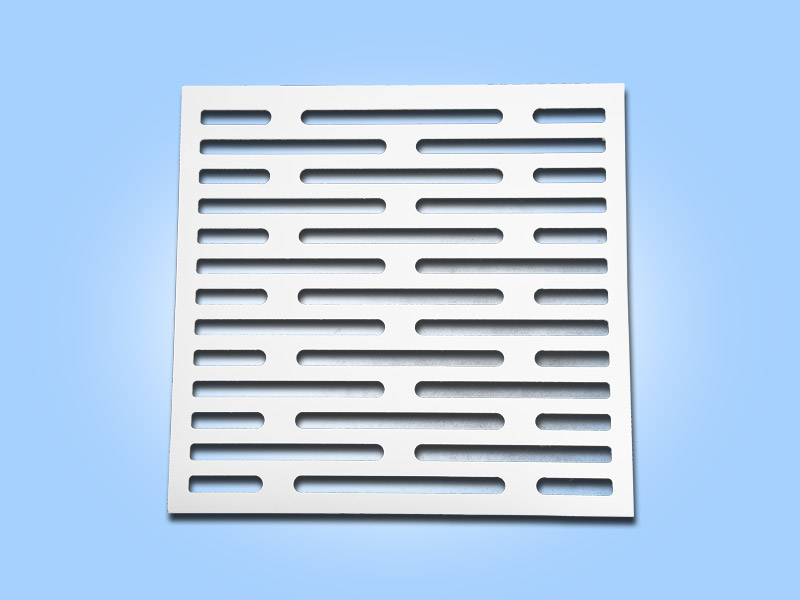

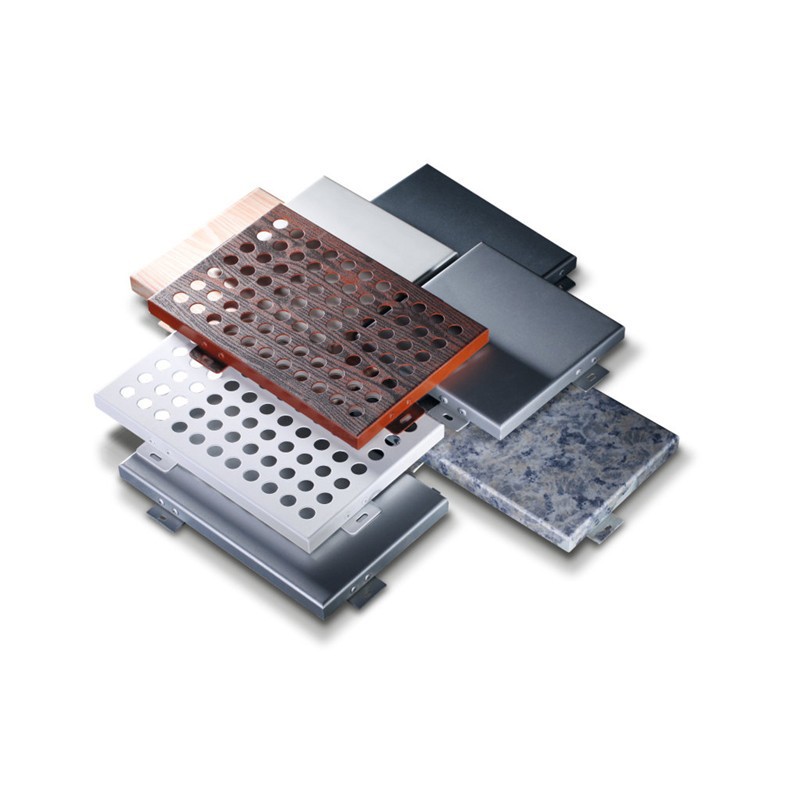

First of all, let's talk about the name honeycomb aluminum plate. Does it sound a bit high-end? It is like its name, densely packed like a honeycomb, but made of aluminum. The structure of this material is unique, with thin aluminum plates stacked layer by layer to form hexagonal honeycomb shapes, hence it is called honeycomb aluminum plate.

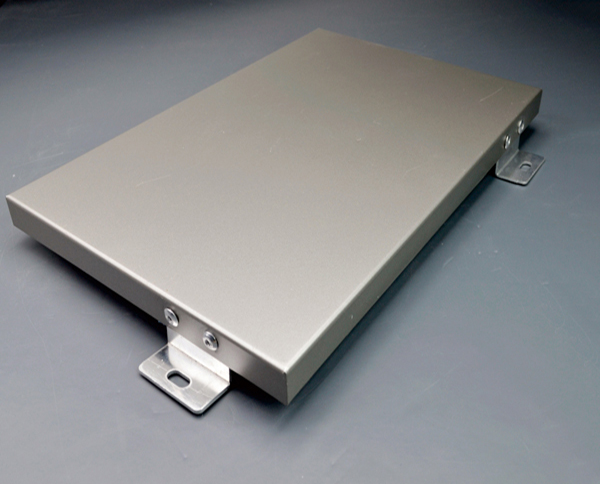

The most amazing thing about honeycomb aluminum panels is their lightweight design. You may think aluminum is heavy, right? Honeycomb aluminum plate can maintain high strength while reducing weight. It's like if you put two wooden sticks of the same thickness on your shoulders, one solid and the other hollow, can you feel which one is heavier? The answer is hollow because its interior is hollow, so it is lighter. The principle of honeycomb aluminum plate is the same.

Speaking of which, I can't help but think of a toy I had when I was a child - a skateboard. At that time, I always envied those classmates whose scooters were particularly lightweight, as they could easily ride on the campus playground. Later on, I found out that their scooters were made of honeycomb aluminum panels. This lightweight scooter allows me to play freely on the playground without worrying about getting injured when I fall.

Honeycomb aluminum plate not only has its presence in toys, but also shines brightly in electronic products. For example, the shells of mobile phones, laptops, tablets, etc. are mostly made of honeycomb aluminum panels. Why? Because honeycomb aluminum plates can effectively absorb vibrations and impacts, protecting the precision components inside. Its heat dissipation performance is also very good, which can effectively prevent equipment from overheating.

Let's talk about the application of honeycomb aluminum plate again. It is not only widely used in electronic products, but also demonstrates its capabilities in fields such as aerospace, transportation, and construction. For example, honeycomb aluminum panels can be seen on the fuselage of airplanes, the chassis of high-speed trains, and the exterior walls of buildings. The applications in these fields have made honeycomb aluminum sheets an indispensable and important material for modern industry.

However, honeycomb aluminum panels also have their limitations. Due to the complex manufacturing process and relatively high cost of honeycomb aluminum plates, their application is limited in some fields with high cost requirements. With the continuous development of technology, I believe this problem will gradually be solved.

Speaking of which, I would like to share a little story. Once, my friends and I visited an aerospace exhibition. In the exhibition, we saw a model of an airplane whose body was made of honeycomb aluminum panels. Looking at that plane, I couldn't help but think of my childhood dream - to become an astronaut. Perhaps it is this magical honeycomb aluminum plate that fills me with anticipation for the future.

The niche term 'honeycomb aluminum plate' hides a big technological secret behind it. It is lightweight, sturdy, and has good heat dissipation performance, bringing a lot of convenience to our lives. Although its application fields are limited, with the advancement of technology, it is believed that its applications will become increasingly widespread. Let's look forward together, honeycomb aluminum panels can create more miracles in the future!

Customer service QQ

Customer service QQ