Corporate News

Company News

- Aluminum veneer: the 'silver canvas' in modern architecture

- Aluminum honeycomb panel: the 'hidden hero' of the construction industry?

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum ceiling, the new darling of modern space

- Aluminum ceiling: the beauty of lightness, the new darling of architecture

Industry dynamics

- Customized aluminum veneer, creating a new trend of personalized space!

- The beauty of aluminum ceiling, a hidden highlight in home decoration

- Aluminum curtain wall, the magnificent coat of modern architecture

- The new trend of aluminum ceiling reveals the "beauty of the sky" in modern architecture

- The secret world of honeycomb aluminum plate: as light as a feather, as solid as a rock!

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

- What is the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

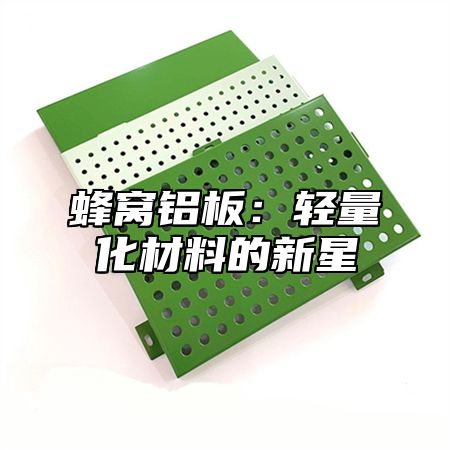

Honeycomb aluminum plate: the new star of lightweight materials

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 3, 2025 23:31:46

- Click:0

Ladies and gentlemen, today let's talk about a magical material - honeycomb aluminum plate. You may ask, what's special about honeycomb aluminum panels? Don't worry, listen to me slowly.

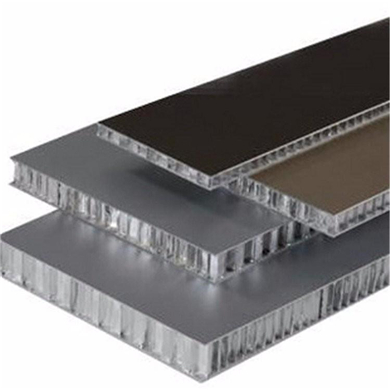

Honeycomb aluminum plate, as the name suggests, is a composite material made of aluminum plate with honeycomb structure as the basic unit. Speaking of which, you may ask, what are the benefits of honeycomb structure? Honeycomb structure can reduce material weight while maintaining high strength and stiffness. Does it sound impressive? Don't worry, that's not all the charm of honeycomb aluminum panels.

We need to talk about the lightweighting of honeycomb aluminum panels. Do you know that the quality of honeycomb aluminum plate is only 1/5 to 1/4 of traditional aluminum plate, while its strength is not inferior. This means that using honeycomb aluminum panels can make products lighter, thereby reducing transportation costs and improving energy efficiency. For example, if we use honeycomb aluminum panels to make the fuselage of the plane we usually fly on, the total weight of the plane can be reduced significantly, and the flight efficiency can also be improved.

Let's talk about the stiffness of honeycomb aluminum plate again. The honeycomb structure enables the honeycomb aluminum plate to evenly distribute pressure when subjected to external forces, thereby improving the stiffness of the material. This characteristic has a wide range of applications in fields such as architecture, automotive, aerospace, etc. In the field of architecture, honeycomb aluminum panels can be used to make lightweight and high-strength roof panels, wall panels, etc., which can reduce the weight of buildings and improve seismic performance.

How is honeycomb aluminum plate made? The production process of honeycomb aluminum plate is not complicated. Press the aluminum plate into a honeycomb structure, and then combine the honeycomb aluminum plate with other materials through welding, bonding, and other processes. In this way, honeycomb aluminum sheet was born.

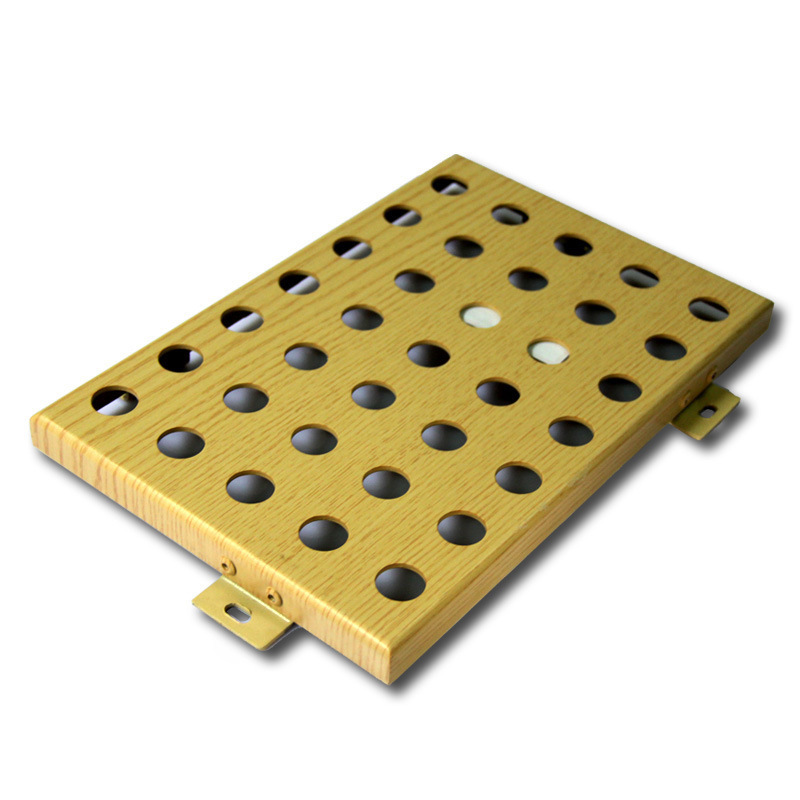

The application fields of honeycomb aluminum panels are very extensive, covering almost multiple fields such as industry, construction, aerospace, transportation, etc. Below, I will give you a few examples.

Let's take a look at the aerospace industry. Honeycomb aluminum plates are widely used in the aerospace industry, such as airplanes, missiles, satellites, etc. Aircraft bodies made of honeycomb aluminum panels can reduce weight, improve fuel efficiency, and lower flight costs. Honeycomb aluminum plate also has good corrosion resistance, which can extend the service life of aircraft.

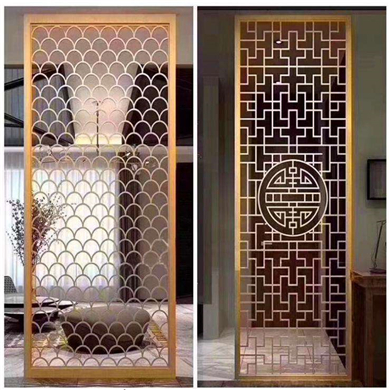

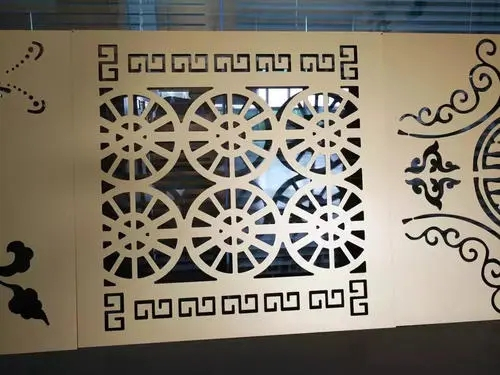

Let's talk about the field of architecture again. Honeycomb aluminum panels also have a wide range of applications in the field of construction, such as roof panels, wall panels, decorative panels, etc. Buildings made with honeycomb aluminum panels can not only reduce their own weight and improve seismic performance, but also lower construction costs. Honeycomb aluminum panels also have excellent properties such as fire resistance, sound insulation, and thermal insulation, making buildings more environmentally friendly and comfortable.

Let's take a look at the field of transportation. Honeycomb aluminum sheets are also widely used in transportation vehicles such as cars, trains, and ships. Vehicles made of honeycomb aluminum panels can reduce their weight, improve fuel efficiency, and lower emissions. Honeycomb aluminum plate also has good corrosion resistance, which can extend the service life of transportation vehicles.

Honeycomb aluminum panels also have some shortcomings. Its cost is relatively high and the processing difficulty is high. With the continuous development of technology, these problems are gradually being solved.

I want to share a personal experience. Once, I visited a factory that produces honeycomb aluminum panels. There, I witnessed the production process of honeycomb aluminum panels with my own eyes and felt the charm of this technology. At that time, I was thinking that if China could increase its investment in the research and development of honeycomb aluminum panels, we could occupy a larger market share in fields such as aerospace and construction.

Honeycomb aluminum plate, as a lightweight material, has high application value. With the continuous development of technology, I believe that honeycomb aluminum panels will play an important role in more fields. Hey guys, what do you think of honeycomb aluminum panels? Welcome to leave a message in the comment section for communication.

Customer service QQ

Customer service QQ