Corporate News

Company News

- The Beauty of Aluminum Ceiling: The Invisible Soul of Modern Architecture

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Honeycomb aluminum plate: a perfect combination of lightweight and aesthetics

- Aluminum veneer, the 'invisible hero' of modern architecture

- The magnificent transformation of aluminum veneer: from ordinary to extraordinary

Industry dynamics

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

- Is the use of aluminum veneer limited by building height?

- Analysis and Prediction of the Market Prospects for Aluminum Veneer Customization

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, create your personalized space

Frequently asked questions

- What are the main uses of aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the characteristics of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

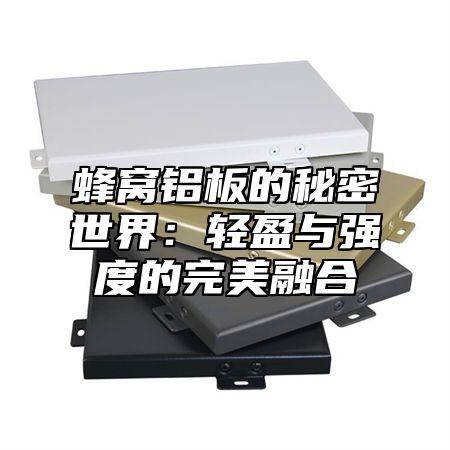

The Secret World of Honeycomb Aluminum Plate: The Perfect Fusion of Lightness and Strength

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 05:49:05

- Click:0

Dear readers, today we are going to unveil a magical substance - honeycomb aluminum plate! You may not be familiar with this name, but it holds a significant position in fields such as aviation and architecture. Let me lead you into the secret world of honeycomb aluminum panels and see how it perfectly blends lightness and strength.

Let's first get to know honeycomb aluminum panels. Honeycomb aluminum plate, as the name suggests, is a composite material composed of honeycomb structure and aluminum plate. This structure endows honeycomb aluminum plates with excellent bending strength, torsional strength, and good sound and heat insulation performance. You may ask, how was such a miraculous substance born? This starts with its manufacturing process.

The production process of honeycomb aluminum plate is not complicated, mainly divided into the following steps:

1. Making honeycomb core: We need to cut the aluminum plate into a certain size and then process it into a honeycomb structure through special technology. This process is like filling aluminum plates in a honeycomb, forming a unique honeycomb core.

2. Assembly: Combine the prepared honeycomb core with an aluminum plate to form a complete honeycomb aluminum plate.

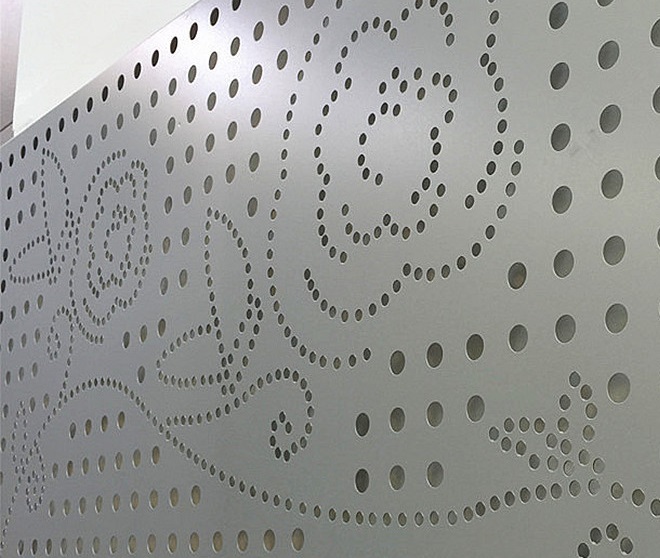

3. Coating: In order to improve the corrosion resistance and aesthetics of honeycomb aluminum plates, we will also perform coating treatment on them.

4. Finished product: After the above process, the honeycomb aluminum plate is completed.

Let's take a look at the application of honeycomb aluminum panels in various fields!

1、 Aerospace field

In the aerospace industry, honeycomb aluminum plates are highly favored due to their excellent performance. The wings, tail and other parts of the aircraft are made of honeycomb aluminum panels. In this way, it not only reduces the weight of the aircraft, but also improves its structural strength, making the aircraft more stable and efficient during flight.

2、 Construction field

In the field of construction, honeycomb aluminum panels also play an important role. Honeycomb aluminum panels are used for curtain walls, roof panels, and other high-rise buildings. This material not only has good thermal insulation performance, but also has a beautiful and elegant appearance, making the building more artistic.

3、 Transportation field

Honeycomb aluminum sheets are also widely used in the field of transportation. The interior and ceiling of vehicles such as cars, trains, and ships are all made of honeycomb aluminum panels. In this way, it not only reduces the weight of the vehicle but also improves ride comfort.

4、 In the field of electronic products

In the field of electronic products, honeycomb aluminum plates also have broad application prospects. Honeycomb aluminum plates are used for the shells, heat sinks, etc. of electronic products such as mobile phones and computers. This material has excellent heat dissipation performance, which helps to improve the service life of electronic products.

How does honeycomb aluminum plate achieve a perfect fusion of lightness and strength?

1. Honeycomb structure: The honeycomb core structure of honeycomb aluminum plate gives it excellent compressive strength and bending strength. This structure allows the honeycomb aluminum plate to disperse stress and reduce deformation when subjected to force.

2. Aluminum plate material: Aluminum plates have excellent strength and toughness, allowing them to withstand certain pressure when subjected to force. Aluminum plates have good corrosion resistance, allowing honeycomb aluminum plates to maintain stable performance even in harsh environments.

3. Precision manufacturing: The production process of honeycomb aluminum plate requires precision, which ensures a tight bond between the honeycomb core and the aluminum plate, thereby improving the overall strength.

Honeycomb aluminum sheets have achieved significant application results in various fields due to their unique structure and excellent performance. In the future, with the continuous development of technology, we believe that honeycomb aluminum panels will play a greater role and bring more convenience to our lives.

What I want to say is that there are still many magical substances in this world, just like honeycomb aluminum panels, which silently contribute to our lives. Let's explore this mysterious material world together and feel the charm of technology!

Customer service QQ

Customer service QQ