Corporate News

Company News

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum curtain wall, the "gorgeous coat" of modern architecture

- Aluminum curtain wall, revealing the 'invisible armor' in architecture!

- The "honeycomb" mystery of aluminum honeycomb panel: light as a feather, indestructible!

Industry dynamics

- Aluminum ceiling, a new chapter in the beauty of architecture

- Stone patterned perforated aluminum veneer creates a new highlight for building exterior walls

- Innovative design door head 2.0mm aluminum veneer

- Aluminum ceiling: low-key luxury in modern architecture

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

Frequently asked questions

- What is the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- How to increase the market demand for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-18 20:01:51

- Click:0

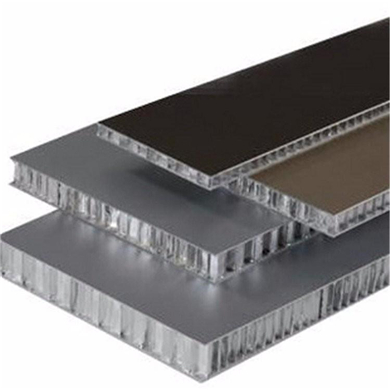

Friends, today let's talk about a magical material - honeycomb aluminum plate. Does this name sound a bit fancy? That's right, it does have some originality. Honeycomb aluminum plate, as the name suggests, is an aluminum plate that imitates the honeycomb structure. It may sound a bit complicated, don't worry, let me explain it slowly.

We need to talk about the origin of this honeycomb aluminum plate. Do you know that it was first born in the United States in the 1950s. At that time, scientists had a brilliant idea to create a lightweight and sturdy material, and came up with the honeycomb of bees. Although the structure of a honeycomb may seem simple, it has extremely high mechanical properties, being lightweight and stable. Honeycomb aluminum sheet was born in this way.

Speaking of which, you may have a question: What is the magical thing about honeycomb aluminum panels? Let me reveal it to you. It's light. Do you know that the density of honeycomb aluminum plate is only about one-third of aluminum, which means that under the same volume, its weight is only one-third of aluminum plate. Imagine if you were holding a honeycomb aluminum plate in your hand, you would hardly feel its weight, like holding a feather. This is a significant advantage, especially in fields such as aerospace and automotive manufacturing, where lightweighting is crucial.

Let's talk about its durability again. You may think that since it's so light, it should be very fragile, right? On the contrary, honeycomb aluminum panels are not only lightweight, but also very sturdy. This is because of its structural characteristics. Honeycomb aluminum plate is composed of countless hexagonal honeycomb units, which are interconnected to form a stable grid structure. This structure enables the honeycomb aluminum plate to effectively disperse pressure when subjected to external forces, thereby improving the material's bending, torsion, and compression resistance.

How does honeycomb aluminum plate perform in practical applications? Let me give you an example. Do you know that the world's largest passenger plane, the Boeing 747, uses honeycomb aluminum panels for its wings. This material not only reduces the weight of the aircraft, but also increases the strength and stiffness of the wings, making the aircraft more stable during flight. In addition, the bogies of high-speed trains, suspension systems of cars, and even the backboards of some high-end mobile phones all use honeycomb aluminum panels.

However, honeycomb aluminum panels are not without their drawbacks. Its cost is relatively high. After all, good things are never cheap. The processing difficulty is relatively high. The manufacturing process of honeycomb aluminum plate is relatively complex and requires professional equipment and technology. Recycling is quite difficult. Although honeycomb aluminum panels can be recycled, their complex structure results in higher recycling costs.

Speaking of which, I suddenly remembered a little story from my childhood. At that time, there was a honeycomb aluminum plate at home that my grandfather brought back from the factory. When I was young, I always curiously asked my grandfather, 'Grandpa, what is this? Why is it so magical?' My grandfather always replied with a smile, 'This is a special material that can be used to make many things.' Since then, I have developed a strong interest in honeycomb aluminum panels.

When I see honeycomb aluminum panels again, I always think of my childhood self. I think this may be the charm of science. It not only allows us to understand the mysteries of the world, but also stimulates our curiosity about the unknown world.

Honeycomb aluminum plate is a magical material that is as light as a feather, yet as solid as a rock. Although it has some drawbacks, it cannot be denied that it plays an important role in many fields. I believe that honeycomb aluminum panels will have more applications and bring more convenience to our lives. Friends, what is your opinion on honeycomb aluminum panels? Welcome to leave a comment and share in the comment section!

Customer service QQ

Customer service QQ