Corporate News

Company News

- The 'beauty responsibility' of the aluminum ceiling industry: a new trend of lightweight aesthetics

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum Ceiling: Creating a New Trend in Fashionable Home Furnishings

- Aluminum ceiling, creating a new fashion for modern home decor

- Aluminum curtain wall, the "gorgeous coat" of modern architecture

Industry dynamics

- Aluminum veneer production process and innovation

- Aluminum Curtain Wall: The Beauty of Architecture, the Interpretation of Aluminum

- Four methods for promoting the aluminum veneer market strategy

- 1.5mm roller coated aluminum veneer suitable for various architectural styles to meet individual needs

- How to maintain aluminum veneer?

Frequently asked questions

- How to increase the market demand for aluminum veneer?

- What is the market demand for aluminum veneer?

- What is the future development trend of aluminum veneer?

- What are the main uses of aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The Fantasy Journey of Honeycomb Aluminum Plate: The Mystery Behind Lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-05 22:56:02

- Click:0

Friends, today I am going to take you on a wonderful journey to explore that seemingly ordinary but actually extraordinary honeycomb aluminum plate. You may use it every day, but do you really understand it? Don't worry, come with me and unveil the mysterious veil of honeycomb aluminum plate together!

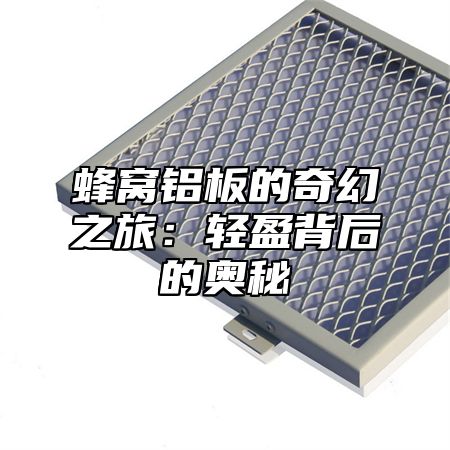

Let's talk about the name honeycomb aluminum plate. Honeycomb? Aluminum plate? This name sounds like a hodgepodge. The name of honeycomb aluminum plate comes from its structure, which is like the honeycomb of a bee, composed of many hexagonal small units. Isn't it a bit unbelievable that this structure makes honeycomb aluminum panels both lightweight and sturdy?

Imagine holding a honeycomb aluminum plate in your hand, which is much lighter than ordinary aluminum plates but can still withstand a lot of pressure. This is the magic of honeycomb aluminum sheet. It can not only be used in the aerospace industry, but also in fields such as construction, packaging, and transportation.

Let's talk about the application of honeycomb aluminum panels in the aerospace industry. The lighter the weight of an airplane, the higher it flies, and the lower its energy consumption. The lightweight and high strength characteristics of honeycomb aluminum plate make it an ideal material for aircraft structural components. Believe it or not, take a look at those planes soaring in the blue sky. Many of their wings, fuselage, and seats are made of honeycomb aluminum panels.

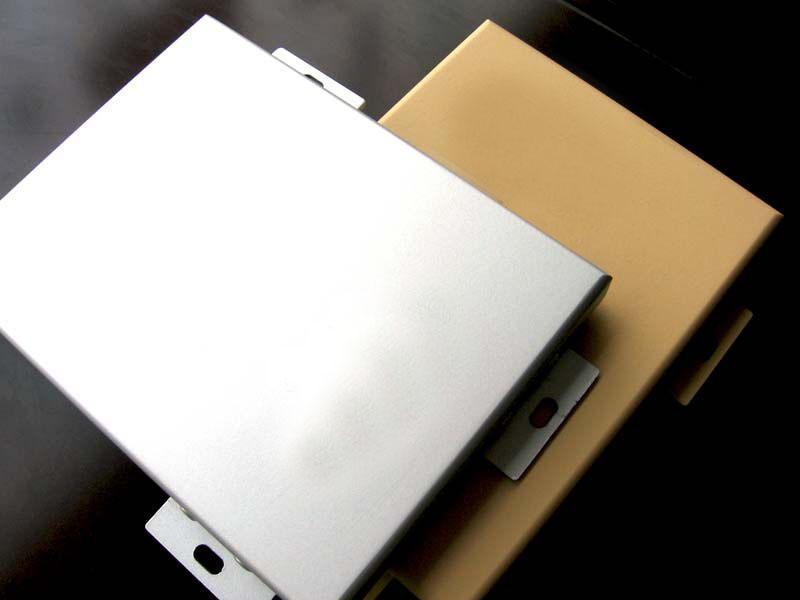

Let's talk about the field of architecture. Honeycomb aluminum panels play an important role in construction. The roofs, curtain walls, and insulation panels of high-rise buildings often rely on honeycomb aluminum panels. Its lightweight and high-strength characteristics make buildings more environmentally friendly and energy-efficient. The surface of honeycomb aluminum plate can be processed into various patterns to make buildings look more beautiful.

The packaging industry cannot ignore the existence of honeycomb aluminum plates. We all know that packaging materials should be lightweight, durable, and environmentally friendly. Honeycomb aluminum panels perfectly meet these requirements. It can be used not only for packaging products such as food, medicine, cosmetics, but also for packaging electronic products and precision instruments, ensuring the safety and worry free transportation of products.

Honeycomb aluminum sheets are also widely used in the field of transportation. Vehicles such as cars, trains, and ships have high requirements for lightweight and strong materials. Honeycomb aluminum plate can perfectly meet these needs. It can make transportation more energy-efficient, environmentally friendly, and improve driving safety.

How is honeycomb aluminum plate manufactured? This is a technical job. Cut the aluminum plate into appropriate sizes and then press it into a honeycomb shape. This process requires high-precision equipment and technology to ensure that the honeycomb structure is uniform and stable. Surface treatment of honeycomb aluminum plate to increase its corrosion resistance and wear resistance.

However, honeycomb aluminum panels also have their shortcomings. Its price is relatively high and the processing difficulty is high. But this cannot stop its development. With the continuous advancement of technology, it is believed that the price of honeycomb aluminum panels will become more affordable and their application scope will become wider and wider.

At this point in the story, you may have gained a deeper understanding of honeycomb aluminum panels. It is like a magician, bringing endless convenience to our lives with its lightweight body. In this magical world of honeycomb aluminum panels, we see the magic of technology and feel the crystallization of human intelligence.

Friends, let's look forward to the future together and hope that honeycomb aluminum panels will shine in more fields. Perhaps in the near future, it will bring us more surprises and changes. Let's embark on this fantastic journey together and explore the infinite possibilities of honeycomb aluminum panels!

Customer service QQ

Customer service QQ