Corporate News

Company News

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum honeycomb panel: a lightweight 'magician' in the construction industry

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

- Aluminum ceiling: the fashionable choice of modern architecture, revealing its charm!

- The 'lightness mystery' of honeycomb aluminum plate: the secret material as light as wings

Industry dynamics

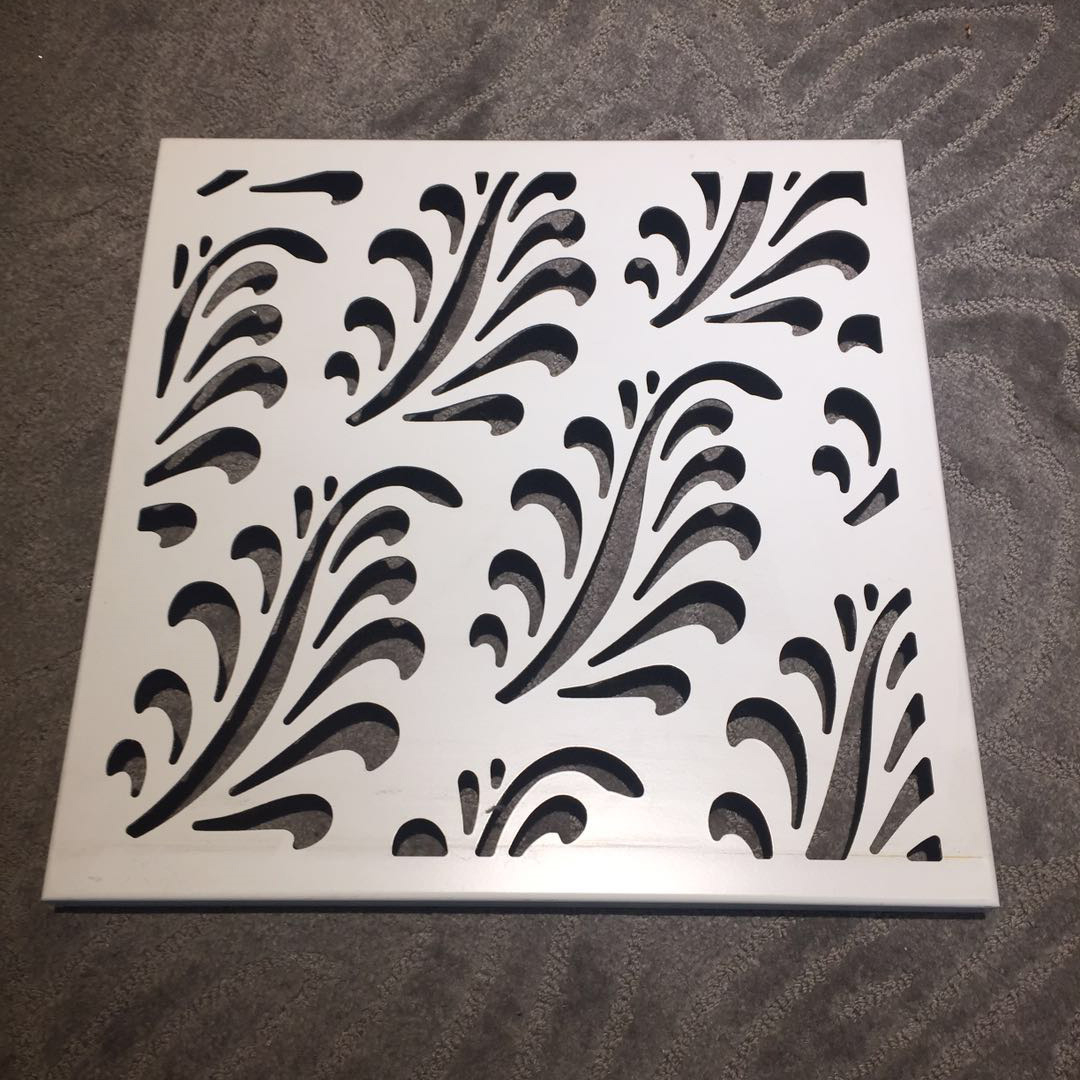

- Customized aluminum veneer, creating a new trend of personalized space

- Honeycomb aluminum plate: the secret behind lightness

- The Fantasy Journey of Aluminum Honeycomb Panels: Material Magic from the Sky

- Anti fouling performance of imitation wood grain aluminum veneer

- Honeycomb aluminum plate: a lightweight choice, the secret weapon of industrial construction

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the main uses of aluminum veneer?

- What is the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

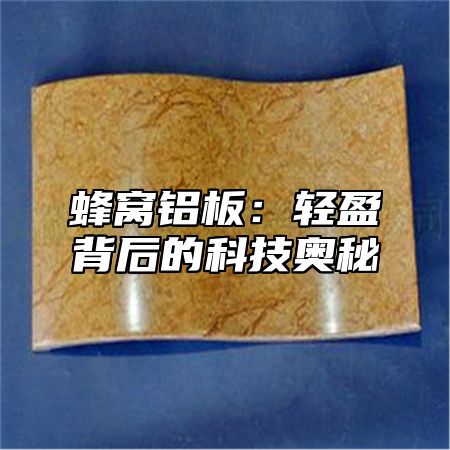

Honeycomb aluminum plate: the technological mystery behind lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-05 04:44:27

- Click:0

Have you ever thought, my friends, that there are so many technological secrets hidden behind those seemingly ordinary honeycomb aluminum panels? I'm here to reveal this mysterious material to everyone.

Let's talk about the name honeycomb aluminum plate. Does it sound a bit high-end? That's right, it's indeed a high-tech product. Honeycomb aluminum plate, as the name suggests, is an aluminum plate composed of a honeycomb structure. This structure gives honeycomb aluminum plates excellent performance in terms of weight, strength, stiffness, and other aspects.

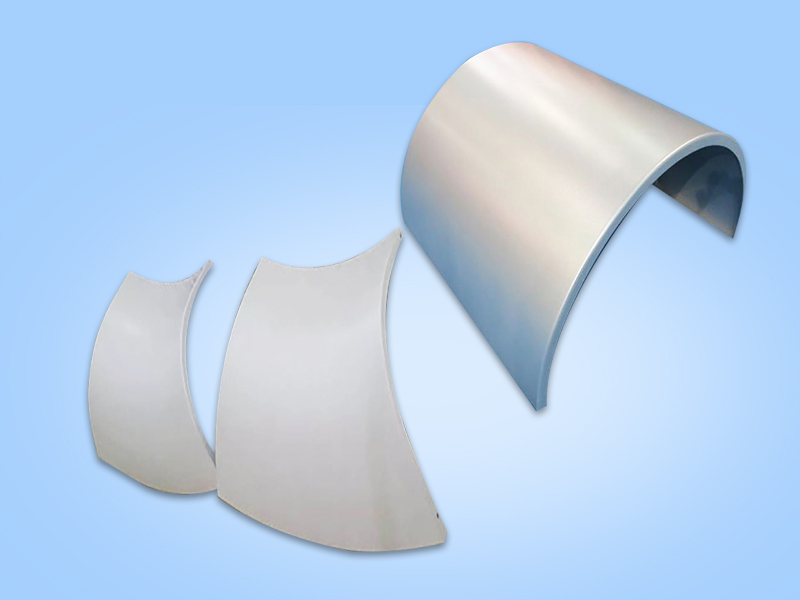

When it comes to weight, honeycomb aluminum panels are as light as a feather. Its density is only about one-third of that of traditional aluminum plates, so it has a wide range of applications in aerospace, automotive manufacturing, and other fields. Don't believe me? Look, which of those cool drones or high-speed trains can do without honeycomb aluminum panels?

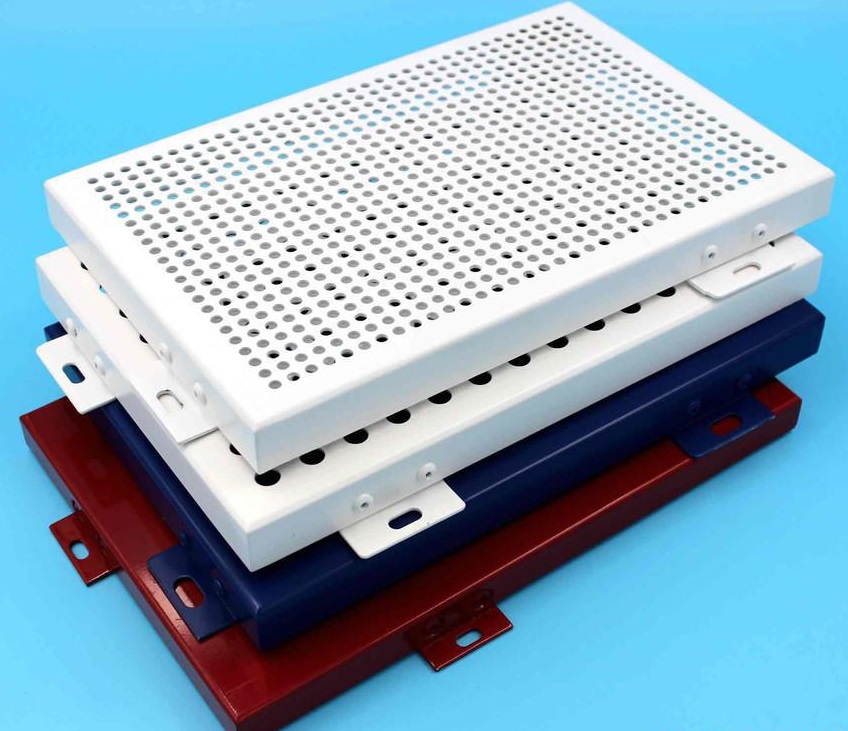

Lightweight is not the only advantage of honeycomb aluminum panels. Its strength and stiffness are also quite impressive. The honeycomb structure enables the honeycomb aluminum plate to evenly distribute stress across the entire surface when subjected to force, thereby improving the material's load-bearing capacity. This is like a honeycomb, where each small cell can share a portion of the weight, making the entire honeycomb structure more sturdy.

How is honeycomb aluminum plate made? Here we have to mention a magical technology - vacuum forming. Place the aluminum plate in a vacuum environment and form a honeycomb structure by heating and applying pressure. This process may seem simple, but it is actually full of technological content. The vacuum environment can ensure a smooth surface of the aluminum plate and high forming accuracy; Heating and pressurization make the honeycomb structure more compact, improving the performance of the material.

The application field of honeycomb aluminum plate is quite extensive. In the aerospace field, it is used to manufacture components such as wings and tail fins of aircraft, which can reduce the weight of the aircraft and improve flight efficiency. In the field of automobile manufacturing, honeycomb aluminum plates are used to manufacture components such as the body and chassis of cars, which can improve the load-bearing capacity and fuel efficiency of cars. It is also applied in fields such as architecture, electronics, and sports equipment.

However, honeycomb aluminum panels also have their limitations. It has a high cost and is not suitable for large-scale application. The processing difficulty of honeycomb aluminum plate is relatively high, requiring professional equipment and technology. The recycling and reuse of honeycomb aluminum plates is relatively difficult, which has a certain impact on the environment.

What should we do in the face of these limitations? I think we can start from the following aspects:

1. Optimize production processes and reduce production costs. Through technological innovation, improve production efficiency and reduce material costs.

2. Strengthen environmental awareness and improve recycling efficiency. Research new recycling technologies to reduce their impact on the environment.

3. Explore the application of honeycomb aluminum panels in other fields and expand market space. In the field of architecture, honeycomb aluminum panels can be used to manufacture lightweight walls, ceilings, etc.

Honeycomb aluminum plate, this seemingly ordinary material, contains rich technological connotations behind it. With the continuous development of technology, I believe its future application prospects will be even broader. Hey guys, what do you think of honeycomb aluminum panels? Welcome to leave a message in the comment section for communication!

Customer service QQ

Customer service QQ