Corporate News

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the beauty of architecture, the soul of details

- Aluminum honeycomb panel: a new favorite of lightweight and sturdy building materials

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Four methods for promoting the aluminum veneer market strategy

- The Charm of Aluminum Veneer: A New Chapter in the Beauty of Architecture

- Honeycomb aluminum plate: a perfect combination of lightweight and sturdy

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

- Aluminum ceiling: not just the ceiling, but also the guardian of the home

Frequently asked questions

- What are the characteristics of aluminum veneer?

- What is the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the technological power behind lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-15 16:25:50

- Click:0

Ladies and gentlemen, today we will talk about a material that sounds quite high-end - honeycomb aluminum plate. Does this name sound like it popped out of a science fiction movie? Don't worry, let's talk slowly.

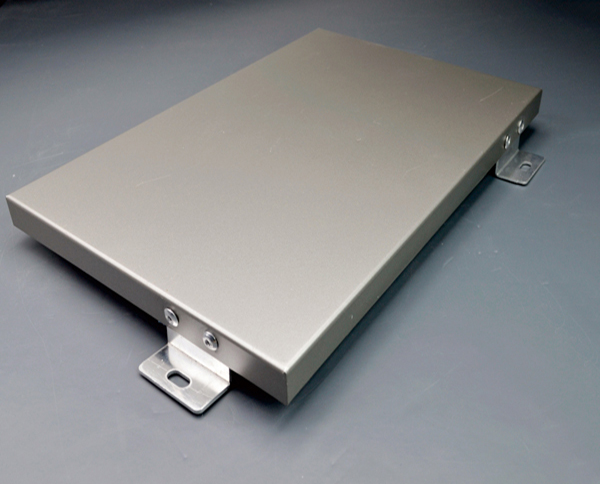

Honeycomb aluminum plate, as the name suggests, is a sheet made of aluminum material based on honeycomb structure. This material is lightweight, sturdy, and impact resistant, and is widely used in fields such as aerospace, automotive manufacturing, and construction. You may think that this thing is quite far from our lives, but in fact, it is right beside us.

I remember one time, I went to attend a groundbreaking ceremony at a construction site. On site, engineers are busy installing honeycomb aluminum panels onto the roof of the building. I curiously asked, "Is there anything special about this honeycomb aluminum plate?" The engineer replied with a smile, "Of course there is. This honeycomb aluminum plate is lightweight, durable, and can also provide insulation and sound insulation

The lightweight of honeycomb aluminum plate is due to its honeycomb structure. This structure imitates the honeycomb of bees, greatly reducing the weight of the material while ensuring strength and rigidity. You may not imagine that a honeycomb aluminum plate may weigh only one-fifth of a steel plate of the same volume. This is the power of technology, making our lives better.

How is honeycomb aluminum plate made? It is made of aluminum plate through special processing technology. Cut the aluminum plate into blocks of a certain size, and then perform surface treatment such as anodizing, painting, etc. to increase its corrosion resistance. The processed aluminum plate is spliced according to the honeycomb structure, and finally subjected to welding, polishing and other processes to obtain the honeycomb aluminum plate.

The durability of honeycomb aluminum plate comes from its unique structure. The honeycomb structure enables materials to disperse and absorb energy when subjected to external forces, thereby improving their impact resistance. Honeycomb aluminum panels also have excellent seismic performance, which can effectively reduce damage to buildings during natural disasters such as earthquakes.

Speaking of which, it is necessary to mention the application of honeycomb aluminum plates in the aerospace industry. The wings, fuselage, and other parts of the aircraft are made of honeycomb aluminum panels. This is because honeycomb aluminum panels are lightweight, sturdy, and can also improve the fuel efficiency of airplanes. According to experts, aircraft made with honeycomb aluminum panels have a fuel consumption that is about 20% lower than traditional aircraft.

The application of honeycomb aluminum plate goes far beyond this. In the field of automobile manufacturing, honeycomb aluminum plates are used in parts such as the body and chassis to improve the strength and stability of automobiles. In the field of architecture, honeycomb aluminum panels are used for roofs, walls, and other areas to provide insulation and sound insulation.

Do honeycomb aluminum sheets also have some shortcomings? The answer is affirmative. The relatively high cost of honeycomb aluminum plate limits its application in some fields. The recycling rate of honeycomb aluminum sheet is relatively low, which has a certain impact on the environment.

Faced with these problems, Chinese researchers are working hard to overcome them. They optimized production processes and reduced raw material costs to make the price of honeycomb aluminum panels more affordable. Develop new honeycomb aluminum plate materials to improve their recycling rate and reduce their impact on the environment.

Honeycomb aluminum plate, as a new type of material, has gradually entered our lives under the promotion of technological development. Behind its lightness lies the power of technology and people's pursuit of a better life. I believe that in the near future, honeycomb aluminum panels will play their role in more fields and bring more surprises to our lives.

Customer service QQ

Customer service QQ