Corporate News

Company News

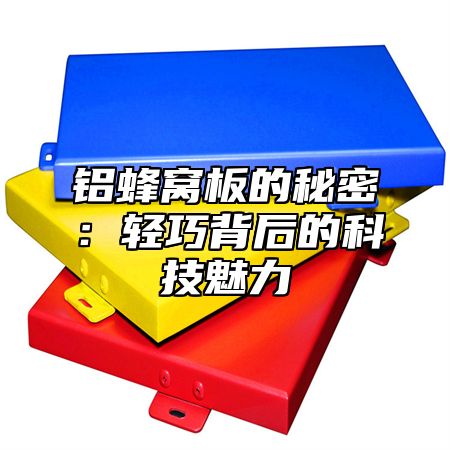

- The secret of aluminum honeycomb panel: light as a feather, indestructible

- Aluminum curtain wall, the dazzling coat of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum honeycomb panel: the 'hidden hero' of the construction industry?

- Aluminum veneer: the beauty of architecture, the choice of light luxury

Industry dynamics

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer is a perfect combination of affordable price, quality, and design

- The trend of environmentally friendly building materials for 2.5mm aluminum veneer

- The charm of honeycomb aluminum plate: the perfect combination of lightness and sturdiness

- Honeycomb aluminum plate: the secret power behind lightness

Frequently asked questions

- What will be the future development trend of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What are the characteristics of aluminum veneer?

- How long is the service life of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The secret of aluminum honeycomb panel: the technological charm behind its lightweight design

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 16, 2025 15:08:52

- Click:0

Dear friends who are interested in building materials, today we will talk about a material that sounds a bit high-end, but is actually very close to our lives - aluminum honeycomb panel. This thing is very lightweight, but there are many technological stories behind it. We need to dig it out carefully.

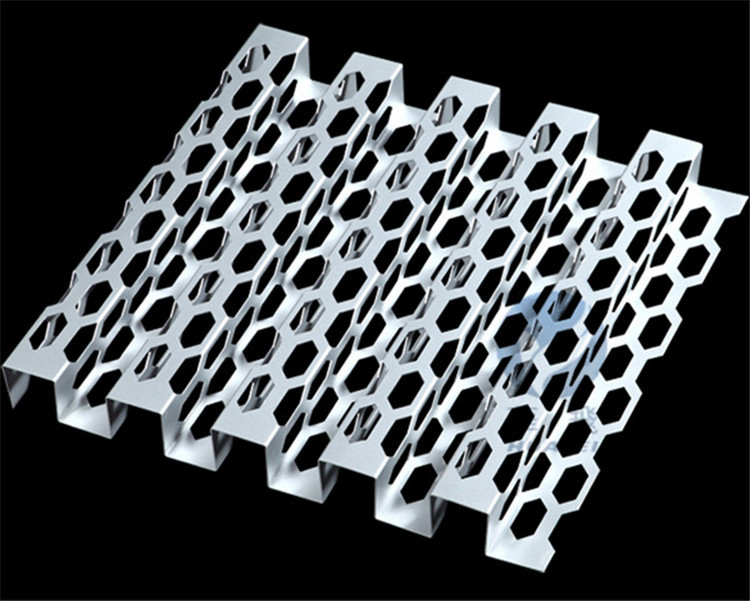

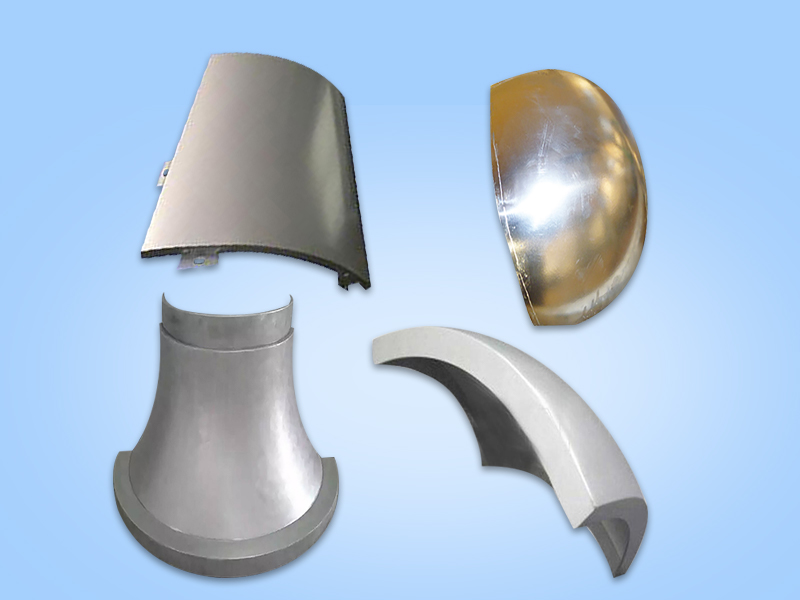

I have to say, the name aluminum honeycomb panel sounds quite high-end, doesn't it? Imagine the honeycomb structure, which is both sturdy and lightweight. When these two characteristics are combined, aluminum honeycomb panels are born. It is lightweight enough to be used in various buildings and decorations, and sturdy enough to withstand enormous pressure, which is its charm.

I remember once I visited a newly built exhibition hall, whose exterior walls were made of aluminum honeycomb panels. From a distance, it looks like delicate pieces of aluminum alloy pasted on top, but up close, wow, that texture and lines are simply works of art! Do you think this material makes people want to explore its production process?

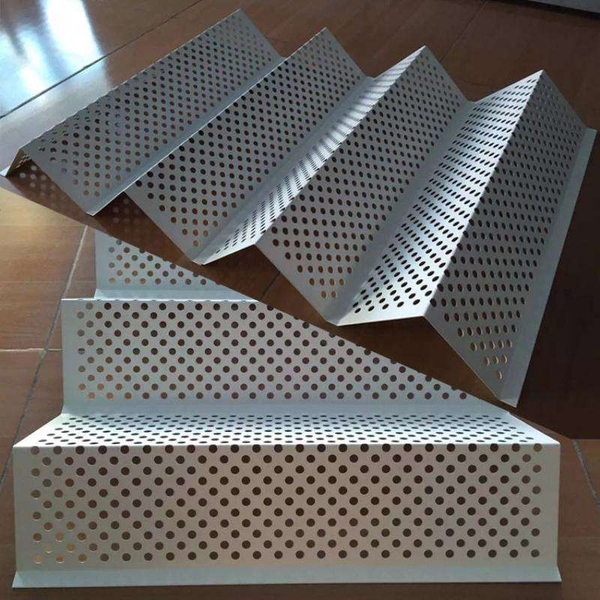

The production process of aluminum honeycomb panels is not complicated, but each step reflects the power of technology. You need to cut the aluminum plate into a specific shape and place it in a specially designed mold. The most crucial step is to fill the honeycomb structure. This is not just about filling in randomly, you need to use special materials such as polystyrene or polyethylene to fill in. Only when filled evenly can the honeycomb structure be firm.

After filling, the aluminum plate and honeycomb structure are welded together. This process requires very precision, as poor welding can cause deformation of the honeycomb structure and affect the performance of the aluminum honeycomb panel. The technological content here is reflected in the precision of welding technology.

Speaking of which, I have to mention the performance of aluminum honeycomb panels. Its biggest feature is its light weight. You know, traditional building materials such as brick walls or concrete have a significant weight. And aluminum honeycomb panels are as lightweight as a piece of paper, which is a huge advantage for buildings. It can greatly reduce the self weight of buildings, lower construction costs, and improve the seismic performance of buildings.

The strength of aluminum honeycomb panels is also quite high. Despite its lightness, its compressive strength and flexural strength are both quite good. This means that it can be used in various buildings, whether they are high-rise buildings, bridges, or even airplanes and ships.

Also, the corrosion resistance of aluminum honeycomb panels is very good. Aluminum itself is a corrosion-resistant metal, and the honeycomb structure can effectively isolate air and moisture. Aluminum honeycomb panels are not easily rusted when used outdoors.

What are the specific applications of aluminum honeycomb panels? It is widely used in the construction industry. Aluminum honeycomb panels can be used for building exterior walls, indoor partitions, ceilings, and various decorative panels. It can not only improve the aesthetics of buildings, but also enhance their safety and durability.

In addition to the construction industry, aluminum honeycomb panels are also widely used in the transportation industry. Aluminum honeycomb panels can be used for the interior of airplanes and ships. Its lightweight and sturdy design allows for better utilization of the interior space of airplanes and ships.

Let's talk about the electronics industry again. Aluminum honeycomb panels also play an important role in the heat dissipation of electronic products. Aluminum honeycomb panels can be used as heat sinks for electronic products such as computer hosts and mobile phones. It has good heat dissipation performance and is lightweight, without increasing the weight of the product.

The application of aluminum honeycomb panels goes far beyond these. It can be seen in the medical industry, sports facilities, furniture manufacturing and other fields. It can be said that aluminum honeycomb panels have become an indispensable part of modern life.

However, we also need to see that aluminum honeycomb panels have their drawbacks. Its price is relatively high. This is because its manufacturing process is complex and the cost is relatively high. The production process of aluminum honeycomb panels will generate certain environmental pollution. When using aluminum honeycomb panels, we should also pay attention to environmental issues.

Aluminum honeycomb panel is an excellent building material. Its lightweight, sturdy, and corrosion-resistant characteristics have made it an important material for modern industries such as construction, transportation, and electronics. Although it has its shortcomings, the flaws do not overshadow its strengths, and its advantages are still evident. I believe that with the continuous development of technology, the application of aluminum honeycomb panels will become more widespread, and our lives will become better because of its existence.

Customer service QQ

Customer service QQ