Industry information

Company News

- Aluminum curtain wall: the beauty of architecture, the light of technology

- Customized aluminum veneer to create your own modern aesthetic space

- Aluminum veneer: a shining pearl in architecture, both environmentally friendly and fashionable

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum Ceiling: Creating a New Trend in Modern Home Furnishings

Industry dynamics

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum ceiling new trend: the fashionable choice for modern architecture

- Aluminum veneer customization, create your personalized space!

- Honeycomb aluminum plate: the industrial secret behind lightness

- Transportation and logistics of aluminum veneer to ensure safe and timely arrival of goods

Frequently asked questions

- What issues should be noted in the production process of aluminum veneer?

- What are the main uses of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What is the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

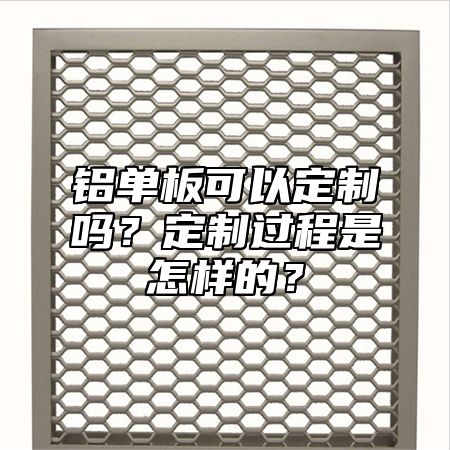

Can aluminum veneer be customized? What is the customization process like?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-27 08:56:37

- Click:0

Aluminum veneer is a common building material, and its customized design can meet the decoration and protection needs of different places. Below, we will provide a detailed introduction to the customization process of aluminum veneer.

1. Determine requirements

Before customizing aluminum veneer, it is necessary to first determine specific usage requirements, including size, color, shape, surface treatment, and other aspects. These requirements can be determined through communication with designers or engineers.

1. Provide design drawings

According to the customer's requirements, the designer will provide corresponding design drawings, including details such as the size, shape, and surface treatment of the aluminum veneer. Customers can modify and improve the design drawings according to their own needs.

1. Choose materials and colors

After determining the design drawings, the customer needs to choose the appropriate aluminum veneer material and color. The color of aluminum veneer can be customized according to customer requirements, and can also refer to existing colors and materials in the market.

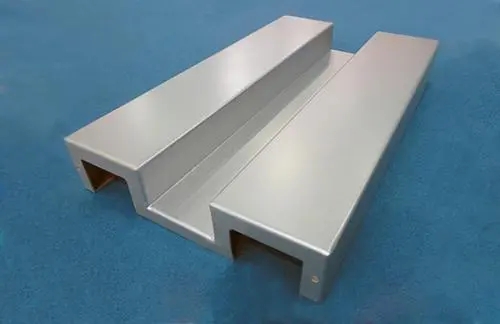

1. Production and manufacturing

After selecting the material and color, the production and manufacturing of aluminum veneer begins. Generally speaking, the production and manufacturing of aluminum veneer require multiple processes, including cutting, bending, stamping, and other techniques. During this process, it is important to ensure the quality and accuracy of the aluminum veneer.

1. Surface treatment

The surface treatment of aluminum veneer is also a very important step. According to customer requirements, different surface treatment methods can be selected, such as anodizing, electrophoretic coating, powder coating, etc. These surface treatment methods can improve the corrosion resistance and aesthetics of aluminum veneer.

1. Installation and maintenance

After completing the customization and production of aluminum veneer, installation and maintenance are required. The installation process needs to be strictly operated according to the requirements of the design drawings to ensure the safety and stability of the aluminum veneer. Regular maintenance and upkeep are also necessary to extend the service life of aluminum veneer.

Aluminum veneer can be customized to meet the decoration and protection needs of different places. During the customization process, it is necessary to have sufficient communication and negotiation with designers or engineers to ensure that the final product meets the customer's requirements and expected results. Strict control of quality and accuracy is also necessary in production, surface treatment, installation, and maintenance to ensure the performance and lifespan of aluminum veneer.

Customer service QQ

Customer service QQ