Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum veneer customization, creating a new choice for personalized space

- The magical world of aluminum honeycomb panels: as light as a feather, as solid as a rock

- Aluminum veneer customization: an artistic journey to create personalized spaces

Industry dynamics

- Aluminum ceiling, creating a new trend in modern home decor

- Aluminum veneer is not just the new favorite of building materials

- Honeycomb aluminum plate: the secret behind lightweight "aluminum"

- The Beauty of Aluminum Ceiling: Simplicity Reveals Luxury

- Unique Design - The Artistic Charm of Hollow Roller Coated Aluminum Veneer

Frequently asked questions

- How to increase the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 8, 2025 15:20:13

- Click:0

Ladies and gentlemen, today let's talk about a magical material - aluminum honeycomb panel. You may not have heard of it, but it has great uses in many places!

Let's talk about the name of this aluminum honeycomb panel. It sounds a bit mysterious, doesn't it? Honeycomb? That's right, its structure is like a honeycomb made by bees, consisting of many hexagonal honeycomb units. This structure is not only beautiful, but also particularly intelligent. Do you know why?

Imagine how much effort it would take for bees to create a solid honeycomb! But the honeycomb is empty, so bees can create a sturdy honeycomb with very little material. The same applies to aluminum honeycomb panels. It consists of two aluminum plates and a honeycomb structure in the middle. In this way, it is both lightweight and sturdy.

Light as a feather, this description is really appropriate. I previously read a data that said the quality of aluminum honeycomb panels is only about 1/10 of that of solid aluminum panels of the same volume. It's like turning a big stone into a light feather, unbelievable, isn't it?

But don't underestimate this lightweight aluminum honeycomb panel, it's as sturdy as a rock. Why is that? Because the honeycomb structure can evenly distribute pressure on the entire surface of the board when subjected to force, it greatly enhances the material's bending and compression resistance. This structure can effectively resist impact and vibration, so aluminum honeycomb panels are preferred in many places that require shock resistance.

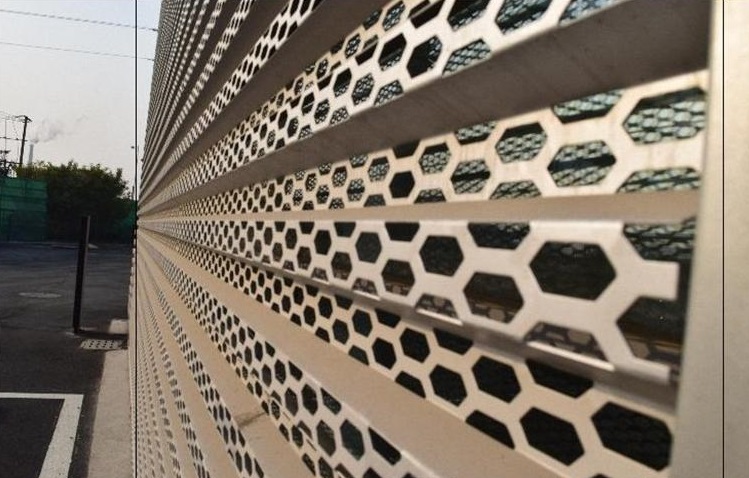

When it comes to applications, aluminum honeycomb panels are truly ubiquitous. It is widely used in the construction industry as exterior wall panels, ceiling panels, roof panels, etc. More and more architects and designers are falling in love with it because it can not only provide insulation and sound insulation, but also be aesthetically pleasing.

I remember one time, I went to visit a newly built office building and was amazed by its appearance. The exterior wall is made of aluminum honeycomb panels, which looks both modern and high-end. According to the staff, this type of board can effectively reduce the energy consumption of buildings, which is truly environmentally friendly and practical.

The applications of aluminum honeycomb panels are not limited to these. In the field of transportation, it is also used to manufacture lightweight components for cars and airplanes. In the electronics industry, it has become the preferred material for high-end electronic product casings. Even in the aerospace field, it has a place.

How is this aluminum honeycomb panel made? Its production process is not complicated. The aluminum plate needs to be cut into the required size and then surface treated to ensure a flat and smooth surface. Send the processed aluminum plate into a honeycomb mold and press it into a honeycomb structure through high temperature and high pressure. The two honeycomb panels are bonded together with adhesive to complete the process.

This is just a simplified process. The production of aluminum honeycomb panels requires strict control over every step to ensure product quality and performance.

Having said so much, you may ask, what are the drawbacks of this aluminum honeycomb panel? Its shortcomings are not many. The biggest drawback may be the price. Due to the complex manufacturing process and high material costs, the price of aluminum honeycomb panels is relatively high. But that doesn't mean it's not worth it. After all, you get what you pay for, and good things naturally won't be cheap.

Aluminum honeycomb panel is a material that is both magical and practical. It is lightweight, sturdy, aesthetically pleasing, and widely used. I believe that with the continuous development of technology, aluminum honeycomb panels will play their role in more fields and bring more convenience to our lives.

Hey guys, do you know any other magical building materials? Welcome to share in the comment section! Let's explore this wonderful world together!

Customer service QQ

Customer service QQ