Industry information

Company News

- Aluminum ceiling: lightweight and fashionable, the new darling of home decoration

- Honeycomb aluminum plate: a modern material adventure of lightweight and high-strength

- The secret of aluminum honeycomb panel: the perfect fusion of lightweight and sturdy

- The secret of aluminum honeycomb panel: the story behind its lightweight structure

- The low-key luxury of aluminum ceiling industry, explore it!

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Advantages and market applications of aluminum veneer

- Installation and maintenance guide for aluminum veneer of irregular curtain wall

- How much wind pressure and impact force can aluminum veneer withstand?

- Sustainable development and environmental characteristics of hyperbolic aluminum veneer with wrapped columns

Frequently asked questions

- What are the main uses of aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the characteristics of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Guidelines for selecting the shape and specifications of 1.5mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-17 22:35:14

- Click:0

1.5mm aluminum veneer is a very common building material, and the selection of its shape and specifications is of great significance for ensuring the aesthetics and practicality of buildings. This article will provide a detailed guide for selecting the shape and specifications of 1.5mm aluminum veneer.

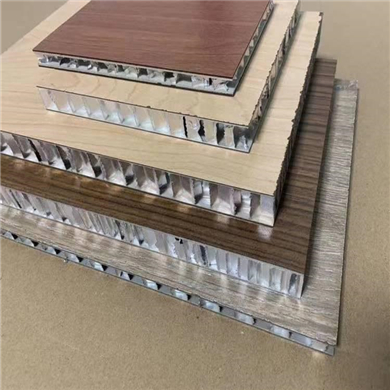

In terms of material properties, 1.5mm thick aluminum veneer usually has certain plasticity and processing performance. This is because the main component of aluminum veneer is aluminum alloy, which has good ductility and processability, and can be processed and customized in various shapes and specifications according to needs. The surface of aluminum veneer can also be treated with some special techniques, such as anodizing, spraying, etc., to further improve its surface quality and decorative effect.

In the selection of shape and specifications, multiple factors need to be considered, including the structure and function of the building, design style, and aesthetic requirements. Generally speaking, the shape and specifications of aluminum veneer can be divided into the following categories:

1. Rectangular aluminum veneer: suitable for large-scale decoration and covering of building exterior walls, roofs, etc.

2. Square aluminum veneer: suitable for decorating and covering small areas such as doors and windows in buildings.

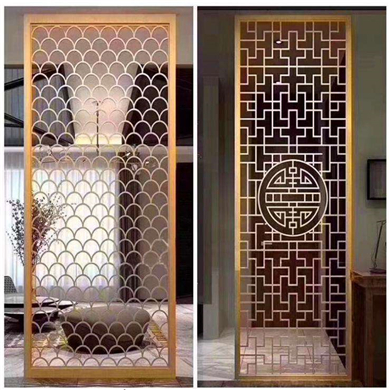

3. Curved aluminum veneer: suitable for decorating complex curved surfaces such as curved walls and arches of buildings.

4. Irregular aluminum veneer: suitable for decoration with special shapes and requirements, such as spherical, elliptical, etc.

It is also necessary to choose different specifications of aluminum veneer according to specific needs, such as size, thickness, color, etc. When selecting specifications, it is necessary to consider factors such as the building's functional use, ventilation, and lighting to ensure that the selected specifications meet the requirements.

In terms of quality inspection and acceptance, it is also necessary to inspect and evaluate the shape and specifications of aluminum veneer. During this process, it is necessary to pay attention to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure that its shape and specifications meet the requirements.

The selection of shape and specifications for 1.5mm thick aluminum veneer is one of its very important advantages. In practical applications, attention should be paid to the quality and effectiveness of the selected materials to ensure better decorative and usage effects, while also paying attention to the processing performance and construction details of the materials.

Customer service QQ

Customer service QQ