Industry information

Company News

- The magical world of aluminum honeycomb panels: as light as a feather, as solid as a rock

- Aluminum curtain wall: the fashionable choice for modern architecture?

- Aluminum veneer: the fashionable outerwear of modern architecture

- The counterattack of aluminum honeycomb panels: an innovative journey of lightweight materials

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- The best choice for high-quality building exterior wall decoration with 2.5mm perforated aluminum veneer

- The magical world of honeycomb aluminum plate: as light as a feather, as solid as a rock

- What is the anti-theft performance of curtain wall aluminum veneer?

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Seismic performance test of 1.5mm aluminum veneer

Frequently asked questions

- What is the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the main uses of aluminum veneer?

- What is the market demand for aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

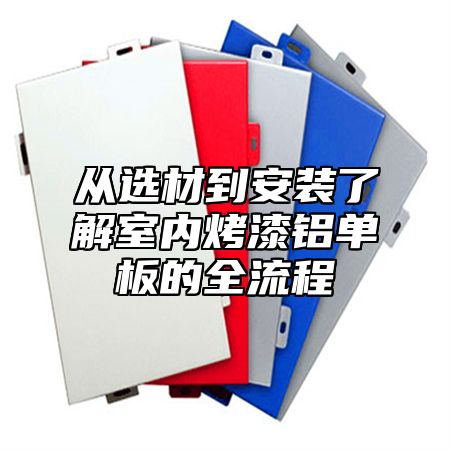

Understanding the entire process of indoor painted aluminum veneer from material selection to installation

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 00:29:08

- Click:0

Indoor painted aluminum veneer is a very popular decorative material, widely used in modern interior decoration. It not only has a beautiful appearance, but also has advantages such as durability and easy cleaning. Below, we will provide a detailed introduction to the entire process from material selection to installation.

1、 Material selection

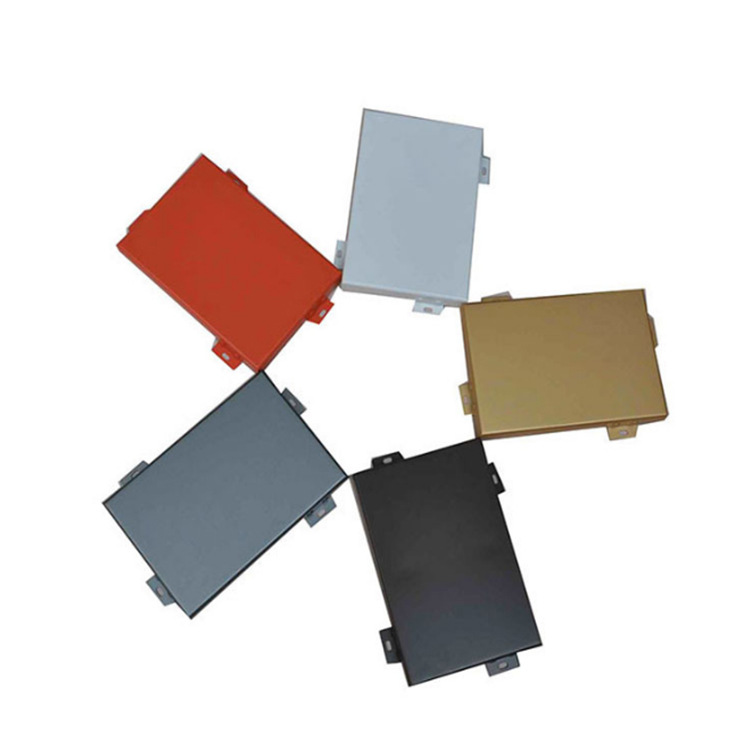

1. Material: Indoor painted aluminum veneer is mainly made of aluminum alloy material, and its surface has been specially treated to present a smooth, flat, and brightly colored effect.

2. Specifications: There are generally multiple specifications available for indoor painted aluminum veneer, including 1200mm, 2400mm, 1500mm, and 3000mm.

3. Thickness: The thickness of indoor painted aluminum veneer is generally between 0.6mm-1.8mm, and can be selected according to actual needs.

2、 Production

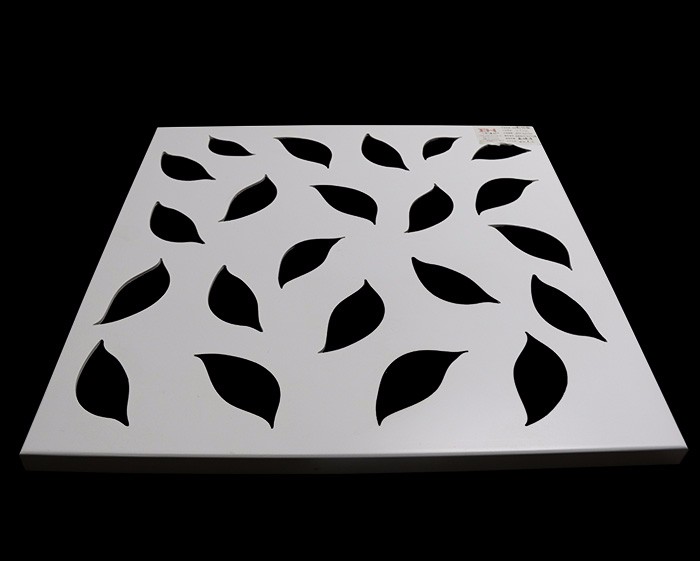

1. Design: Before producing indoor painted aluminum veneer, it is necessary to conduct design to determine the required dimensions, specifications, and other parameters.

2. Cutting: According to the design requirements, cut the aluminum alloy sheet to produce the required indoor painted aluminum veneer.

3. Polishing: Polish the cut indoor painted aluminum veneer to make its surface smoother and smoother.

4. Coating: Apply coating treatment to the polished indoor painted aluminum veneer to present the desired color and effect on its surface.

3、 Installation

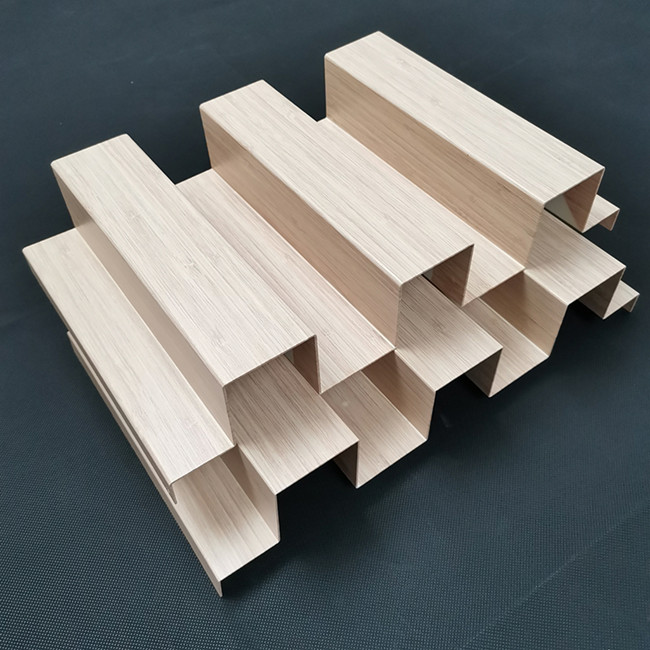

1. Measurement: Before installing indoor painted aluminum veneer, it is necessary to first measure to ensure that the selected size and position of the indoor painted aluminum veneer meet the actual needs.

2. Drilling: Based on the measurement results, drill holes at the location where indoor painted aluminum veneer needs to be installed.

3. Fixation: Fix the indoor painted aluminum veneer to the wall or ceiling through expansion bolts or welding.

4. Inspection: After installation, it is necessary to inspect the indoor painted aluminum veneer to ensure that it is securely installed and meets the required flatness.

The entire process of indoor painted aluminum veneer, from material selection to installation, requires careful production and strict control at multiple stages. Only after a comprehensive understanding of knowledge and skills in all aspects can one make the right choices and do a good job in production and maintenance, bringing more quality and artistic value to their own use.

Customer service QQ

Customer service QQ