Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- The secret of aluminum honeycomb panel: the perfect combination of lightweight and sturdy

- The secret of aluminum honeycomb panel: the technological power behind its lightweight design

- Aluminum ceiling new trend: the elegant choice for modern homes?

- Honeycomb aluminum plate: a perfect combination of lightness and strength

Industry dynamics

- Fluorocarbon curved aluminum veneer is essential for creating high-quality building exterior wall decoration

- Aluminum veneer with wrapped columns - an ideal choice for creating a modern architectural appearance

- Innovative application of aluminum veneer in interior design

- Is it necessary to apply fluorocarbon triple coating to fluorocarbon aluminum veneer?

- Honeycomb aluminum plate: the secret power behind lightness

Frequently asked questions

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What will be the future development trend of aluminum veneer?

- What is the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

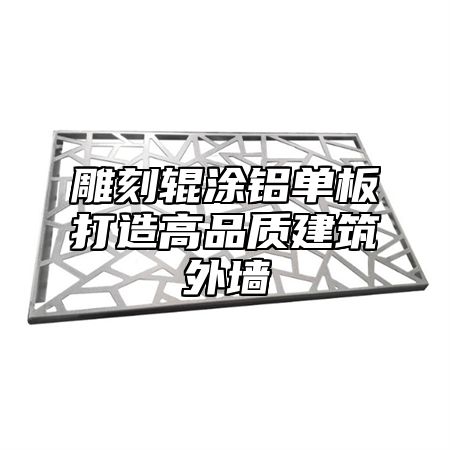

Carving roller coated aluminum veneer to create high-quality building exterior walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-10 20:08:41

- Click:0

With the continuous development of the construction industry and the increasing demand for building appearance, traditional aluminum veneer can no longer meet people's needs. In order to create high-quality building exterior walls, more and more architects and designers are adopting the new material of carved roller coated aluminum veneer. Next, let's introduce in detail the advantages of carving roller coated aluminum veneer.

1、 Design advantages

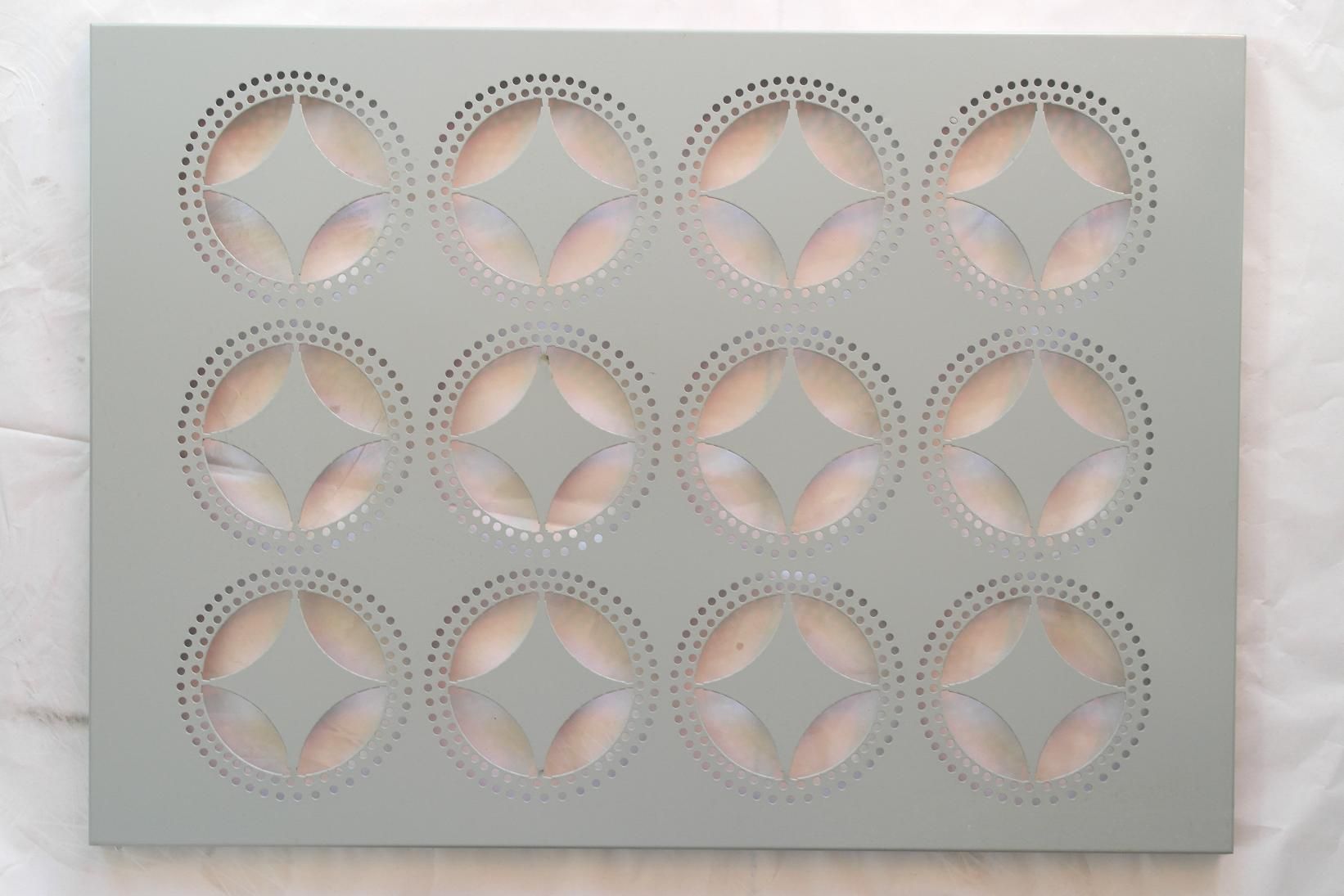

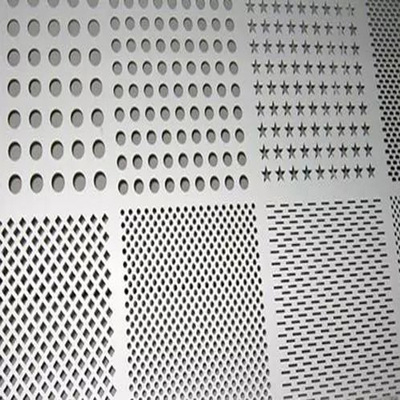

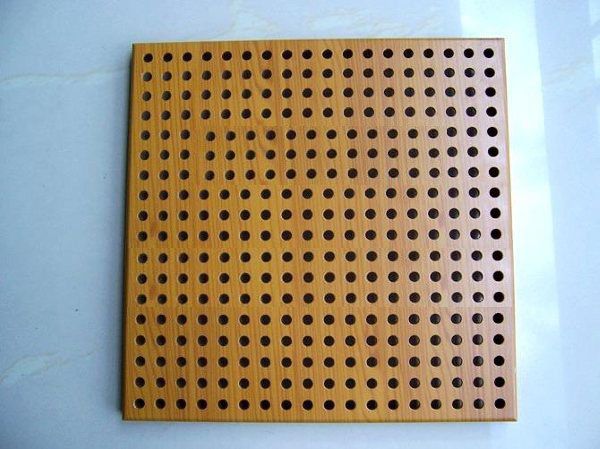

1. Diversified patterns: Traditional aluminum veneers usually only use simple pattern designs, while carved roller coated aluminum veneers can be personalized and customized according to customer needs and building styles to achieve the best decorative effect. Designers can carve according to customer requirements, creating various exquisite patterns and textures to enhance the artistic quality of building decoration materials.

2. Fine carving: The carving roller coated aluminum veneer adopts high-precision carving equipment and technology, which can achieve fine carving of various materials, thereby presenting more exquisite patterns and textures. This process can also be personalized and customized according to customer requirements to meet the needs of different customers.

2、 Material advantages

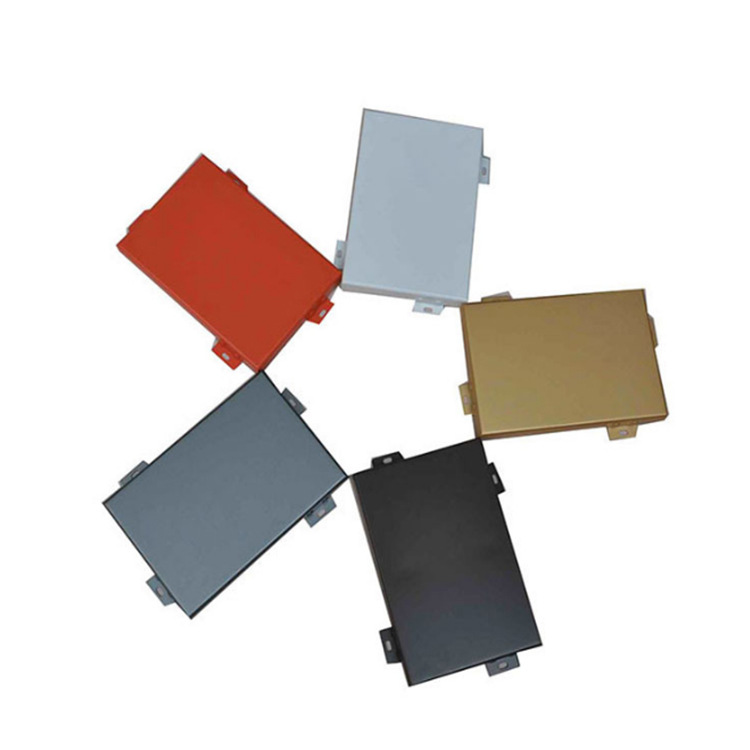

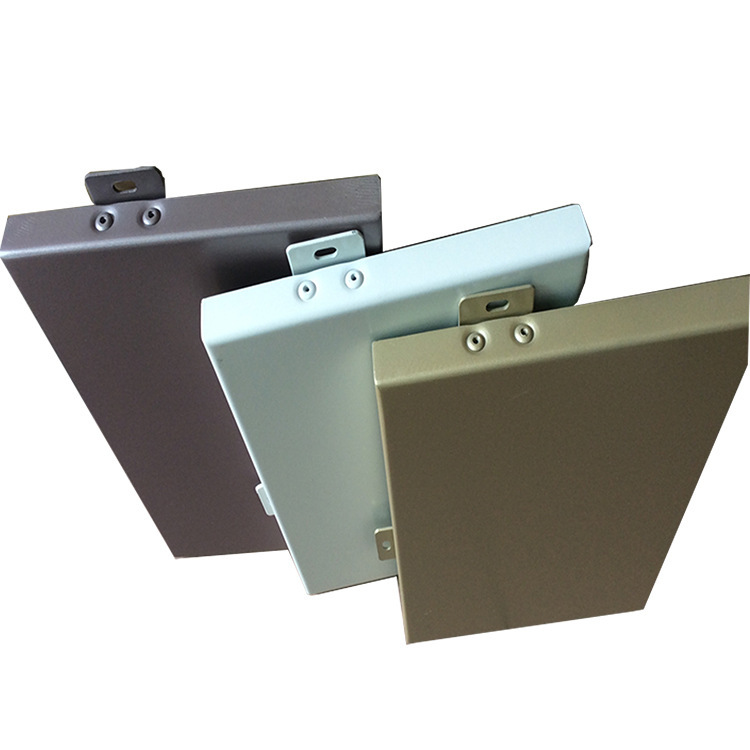

1. Excellent performance: Aluminum veneer has good corrosion resistance, weather resistance, and fire resistance, which can effectively protect the safety and service life of buildings. Aluminum veneer also has good thermal insulation effect, which can reduce energy consumption and achieve energy-saving effect.

2. Environmental protection and energy conservation: The production process of aluminum veneer does not use any harmful substances, which meets environmental protection requirements. Due to its excellent thermal insulation effect, it can reduce energy consumption and achieve energy-saving effects.

3、 Production process

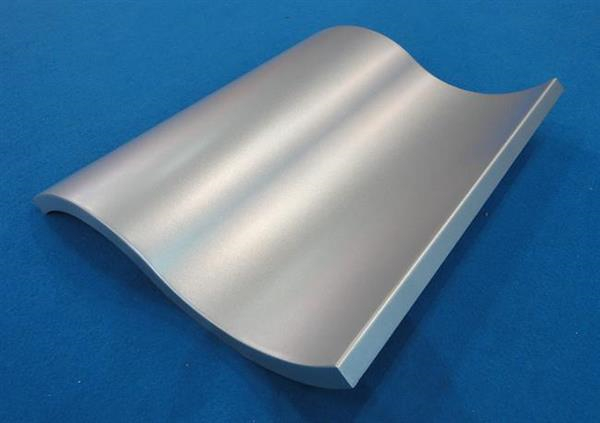

1. Digital production: With the continuous development of digital technology, the production process of engraved roller coated aluminum veneer will also become increasingly digitized. Through the application of digital technology, digital control and management of the entire production process can be achieved, improving production efficiency and quality.

2. Spray coating technology: Spray coating technology is a surface treatment process that can treat various materials. In the production process of carving roller coated aluminum veneer, the use of spraying technology can improve its surface texture and durability, while also increasing its decorative effect.

3. Precision cutting technology: Precision cutting technology is a high-precision and high-efficiency cutting technology that can achieve precise cutting of various materials. In the production process of carving roller coated aluminum veneer, the use of precision cutting technology can improve production efficiency and accuracy, while also reducing the impact on the environment.

Carving roller coated aluminum veneer has high decorative and artistic value, as well as great innovation space and development potential. In the future, with the continuous advancement of technology and the continuous development of society, it will play a more important role.

Customer service QQ

Customer service QQ