Industry information

Company News

- Aluminum curtain wall: the fashionable "coat" of urban architecture

- Aluminum ceiling, poetic embellishment of modern space

- The 'lightness mystery' of honeycomb aluminum plate: the secret material as light as wings

- Aluminum curtain wall: the fashionable choice in modern architecture?

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Exploration of the relationship between outdoor ceiling aluminum veneer and environmental protection

- The secret of honeycomb aluminum plate: a strong shield in lightness

- Honeycomb aluminum plate: the industrial revolution secret behind lightweight structures

- Aluminum curtain wall, the magnificent coat of modern architecture

- Multi functional subway station aluminum ceiling meets different needs

Frequently asked questions

- What will be the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the main uses of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Sharing of maintenance methods for 3mm aluminum veneer in engineering

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-19 04:22:16

- Click:0

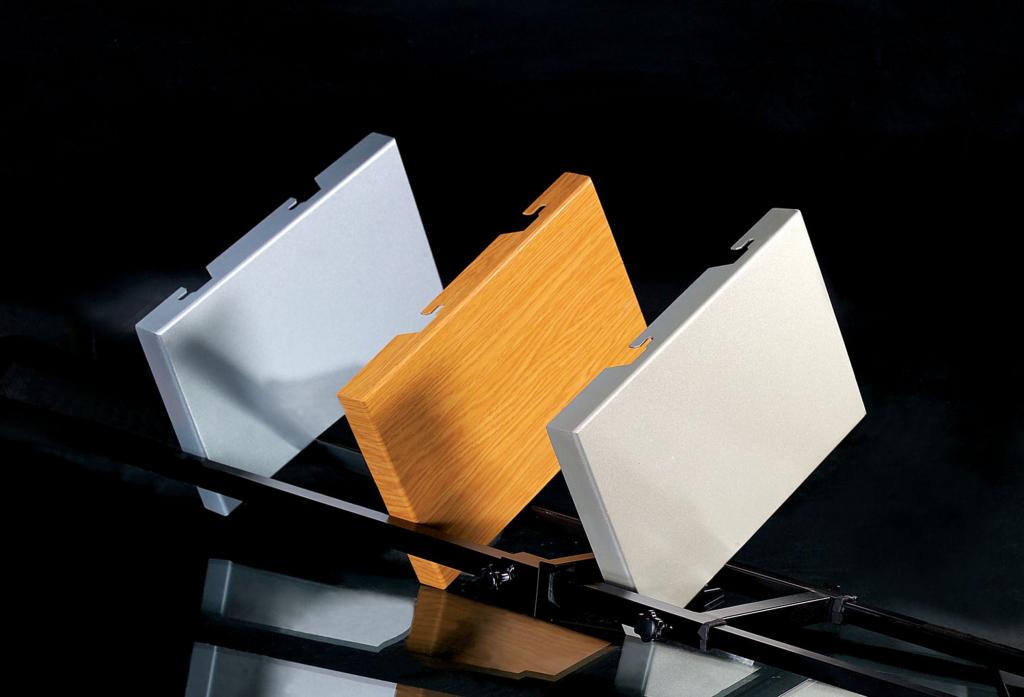

Aluminum veneer is a common building material that has been widely used in modern architecture. During use, aluminum veneer also requires regular maintenance and upkeep to extend its lifespan and maintain its aesthetic appeal. This article will provide a detailed introduction to the maintenance methods of 3mm thick aluminum veneer from the following aspects.

1、 Cleaning and maintenance

1. Surface cleaning: The surface of aluminum veneer should be cleaned regularly, and can be wiped with clean water or neutral detergent. Avoid using acidic or alkaline cleaning agents to prevent damage to the surface oxide film.

2. Stain treatment: For stubborn stains, you can use a soft cloth dipped in a small amount of neutral detergent to gently wipe, avoiding scrubbing with force to avoid scratching the surface.

2、 Anti corrosion maintenance

1. Avoid direct sunlight: Long term exposure of aluminum veneer to sunlight can easily damage the surface oxide film, affecting its appearance and service life. Direct sunlight should be avoided as much as possible, and facilities such as sunshades can be built above the aluminum veneer.

2. Avoid humid environments: Aluminum veneer exposed to humid environments for a long time can easily cause corrosion and rust, so it should be avoided to store and use aluminum veneer in humid environments as much as possible.

3、 Anti pollution maintenance

1. Regular cleaning: Regularly cleaning the surface of aluminum veneer can effectively prevent the accumulation of dust and dirt, improve its appearance and service life.

2. Anti oil treatment: Applying a small amount of anti oil agent on the surface of aluminum veneer can effectively prevent the adhesion of grease and dirt, reduce the frequency and difficulty of cleaning.

4、 Crack prevention and maintenance

1. Avoid collisions: The surface of aluminum veneer is prone to collisions and scratches, so it is advisable to avoid heavy objects or sharp objects from scratching the surface of aluminum veneer during use.

2. Avoid excessive tension: During use, attention should be paid to avoiding applying excessive tension to the aluminum veneer, such as excessive stretching or twisting, to prevent deformation or cracking of the aluminum veneer.

5、 Summary

The maintenance methods for 3mm thick aluminum veneer include cleaning, anti-corrosion, anti fouling, and crack prevention maintenance. Only by operating in accordance with relevant specifications and standards can the quality and stability of aluminum veneer be guaranteed, while also achieving good decorative and usage effects. In practical engineering, attention should be paid to details and safety issues, and operations should be strictly carried out in accordance with relevant regulations to ensure the safety and stability of the entire project.

Customer service QQ

Customer service QQ