Industry information

Company News

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum veneer customization, creating your own personalized space

- Aluminum Curtain Wall: The Aesthetic Choice of Modern Architecture

- The mystery of the "honeycomb" of aluminum honeycomb panel: the secret behind its lightness!

Industry dynamics

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Transportation and storage precautions for fluorocarbon aluminum veneer

- The magical world of honeycomb aluminum plate: as light as a feather, as solid as a rock

- Aluminum veneer: the new darling of industrial aesthetics

- The secret of honeycomb aluminum plate: as light as a feather, as solid as a rock!

Frequently asked questions

- What will be the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- How long is the service life of aluminum veneer?

- What is the market demand for aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

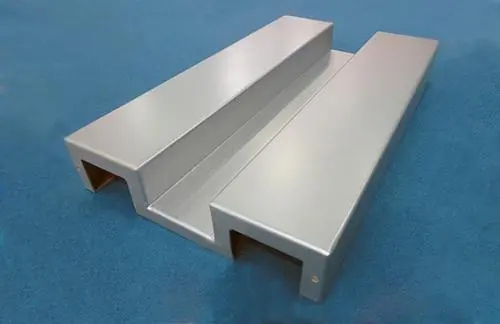

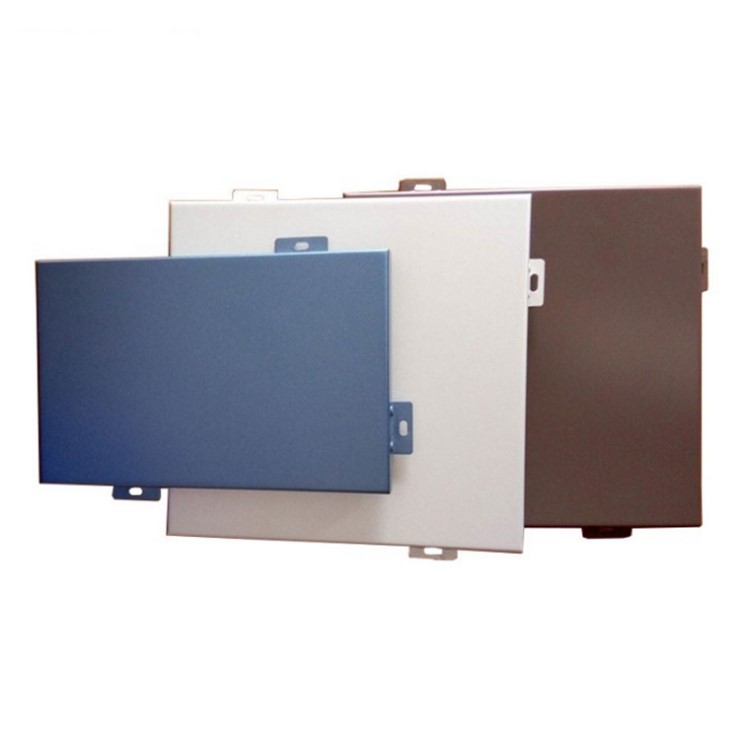

Exquisite craftsmanship creates suspended ceiling roll coated aluminum veneer panels

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 19:29:32

- Click:0

In modern home decoration, the ceiling, as an important component of interior decoration, is receiving increasing attention from people. As a new type of ceiling material, roll coated aluminum veneer panel has become one of the important factors for people to choose due to its exquisite craftsmanship and beautiful appearance. Below, we will provide a detailed introduction on how to create ceiling roller coated aluminum veneer panels through exquisite craftsmanship.

1、 Advantages of roller coated aluminum veneer panel

1. High aesthetic appeal: The surface of the roller coated aluminum veneer panel has undergone special treatment, resulting in excellent glossiness and color saturation, which can present a very beautiful effect.

2. Strong corrosion resistance: The roll coated aluminum veneer panel is made of high-strength aluminum alloy material, which has good corrosion resistance and weather resistance, and can maintain good performance in various harsh environments.

3. Easy installation: Roller coated aluminum veneer panels are lightweight, high-strength, and easy to install without the need for complex construction processes, making it easy to achieve rapid installation.

4. Simple maintenance: The roller coated aluminum veneer panel has a smooth and flat surface, which is not easy to accumulate dust and dirt. It is very easy to clean, just wipe it with a damp cloth.

2、 The specific steps of exquisite craftsmanship

1. Raw material procurement: Firstly, it is necessary to carry out raw material procurement for roll coated aluminum veneer panels, selecting high-quality aluminum alloy materials as the main raw materials.

2. Cutting and processing: According to customer needs and design requirements, carry out cutting and processing of roll coated aluminum veneer panels, including cutting in terms of length, width, thickness, etc.

3. Polishing treatment: After completing the cutting process, it is necessary to polish the roller coated aluminum veneer panel to make its surface smoother and smoother.

4. Spray treatment: After polishing, spray treatment is carried out to increase the aesthetics and color saturation of roller coated aluminum veneer panels.

5. Printing processing: After the spraying process is completed, printing processing work is carried out to increase the pattern and texture of the roller coated aluminum veneer panel.

6. Quality inspection and acceptance: After completing the above procedures, quality inspection and acceptance work is required to check whether the overall effect and quality of the roller coated aluminum veneer panel meet the requirements.

3、 Precautions

During the production process of roll coated aluminum veneer panels, it is important to pay attention to environmental issues and minimize the impact on the environment.

2. When performing spraying treatment, it is necessary to pay attention to safety issues and avoid the generation of harmful gases and dust that can cause harm to human health.

When printing, it is important to pay attention to color selection and matching to achieve the best decorative effect.

Creating ceiling roll coated aluminum veneer panels through exquisite craftsmanship is a very effective method that can improve the aesthetics and practicality of the ceiling. By understanding the advantages of roller coated aluminum veneer panels and the specific steps and precautions of the exquisite process, it is possible to better design and construct suspended ceilings. In the future, with the continuous advancement of technology and the continuous development of society, the application of suspended ceilings will become increasingly widespread and become one of the important choices for people's indoor decoration.

Customer service QQ

Customer service QQ