Industry information

Company News

- Aluminum ceiling: low-key luxury in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating personalized space and new fashion!

- The future development trend of aluminum veneer, as well as its industry competition pattern and challenges

- The magical charm of aluminum honeycomb panels: lightweight, high strength, changing the new chapter of future architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum ceiling, lightweight ceiling new trend

- Honeycomb aluminum plate: the beauty of lightness, hidden industrial secrets

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: a low-key "fashion star" in modern architecture

Frequently asked questions

- What is the market demand for aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What are the characteristics of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

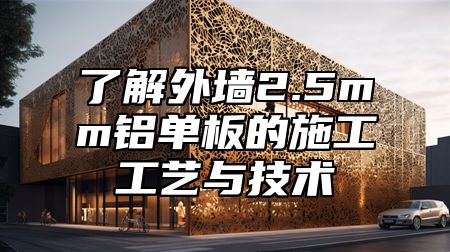

Understand the construction process and technology of 2.5mm aluminum veneer for exterior walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 27, 2025 03:37:29

- Click:0

With the continuous development of the architectural decoration industry, exterior wall decoration materials are becoming increasingly diverse. As a new type of building material, 2.5mm aluminum veneer is highly favored in exterior wall decoration. The following will provide a detailed introduction to the construction process and technology of 2.5mm aluminum veneer.

1、 Preparation before construction

Before carrying out the construction of 2.5mm aluminum veneer, the following preparations need to be made:

1. Determine the design scheme and construction drawings.

2. Clean and level the construction site.

3. Inspect and treat the wall to ensure that the surface is smooth, free of oil stains, loose animals, etc.

4. Prepare necessary construction tools and materials, such as drills, hammers, angle brackets, screwdrivers, level gauges, steel rulers, etc.

2、 Install the keel

Before installing the 2.5mm aluminum veneer, it is necessary to install the keel first. The specific steps are as follows:

1. Determine the position and quantity of the keel according to the design requirements.

2. Drill holes on the wall with an electric drill, and then fix the keel on the wall with self tapping screws.

3. Use a spirit level to check the levelness of the keel, and adjust it if there are any unevenness.

3、 Install corner code

Before installing the 2.5mm aluminum veneer, corner brackets need to be installed first. The specific steps are as follows:

1. Determine the number and location of corner codes according to design requirements.

2. Drill holes on the keel with an electric drill, and then fix the corner code on the keel with self tapping screws.

3. Use a spirit level to check the levelness of the corner code, and adjust it if there are any unevenness.

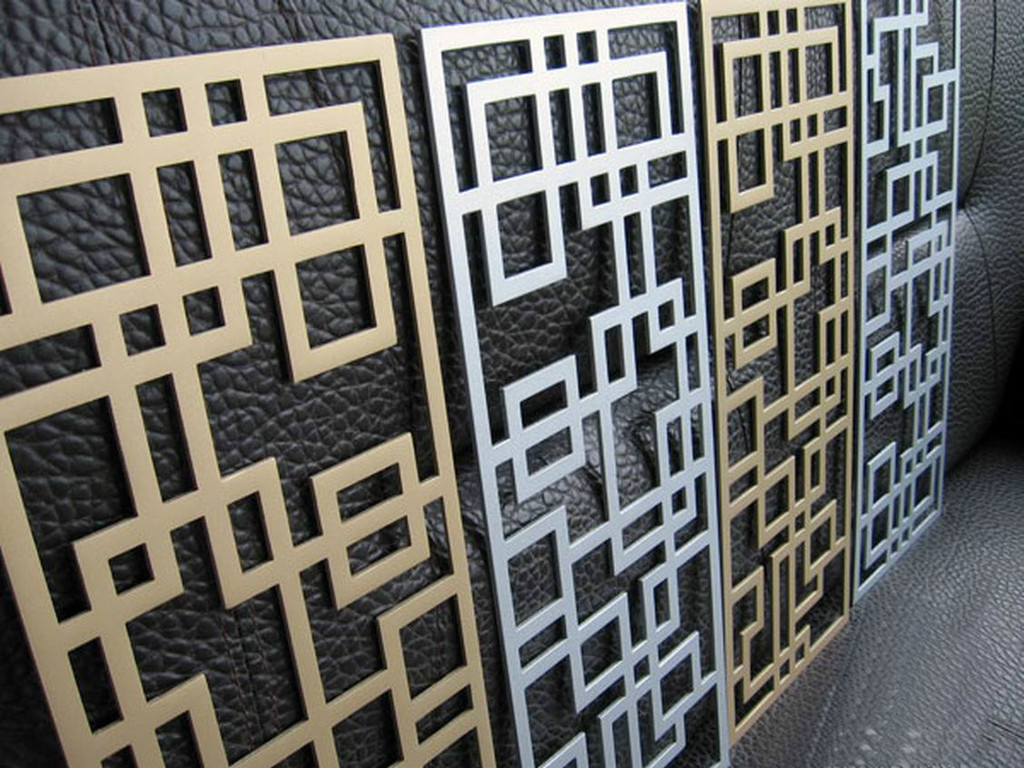

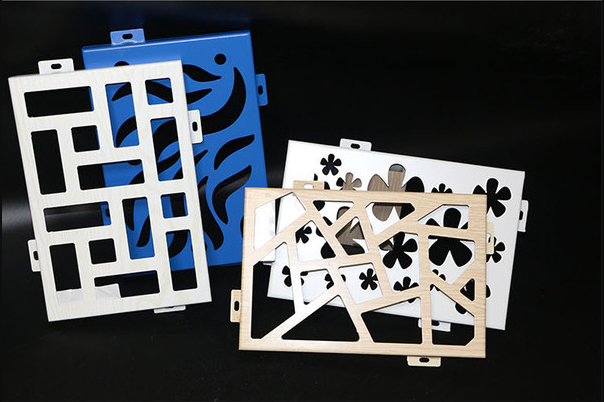

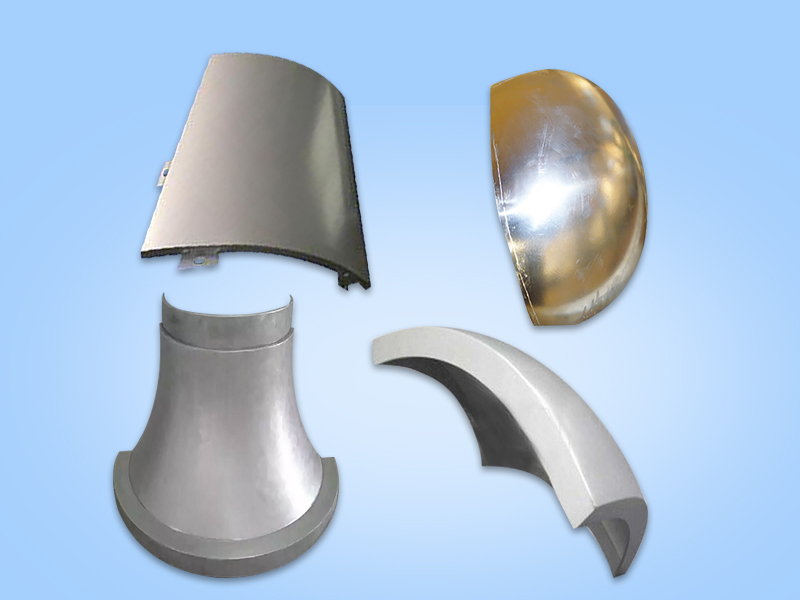

4、 Install 2.5mm aluminum veneer

Before installing the 2.5mm aluminum veneer, it is necessary to first process and bend the aluminum veneer. The specific steps are as follows:

1. Process and bend aluminum veneer according to design requirements.

2. Place the processed aluminum veneer on the corner bracket and fix it to the keel with screws.

3. Use a spirit level to check the levelness of the aluminum veneer, and adjust it if there are any unevenness.

5、 Complete the closing work

After installing the 2.5mm aluminum veneer, the following finishing work needs to be carried out:

1. Clean and repair the surface of aluminum veneer.

2. Apply waterproof treatment to the connection.

3. Clean and organize the construction site.

The above is the construction process and technology for 2.5mm aluminum veneer. By strictly following the above steps, the installation quality and effectiveness of the aluminum veneer can be ensured. During the construction process, it is also necessary to pay attention to safety issues to avoid accidents.

Customer service QQ

Customer service QQ