Industry information

Company News

- Honeycomb aluminum plate: the industrial secret behind lightness

- Honeycomb aluminum plate: a lightweight choice, the beauty of industry

- Aluminum ceiling, the 'invisible guardian' of modern architecture

- Aluminum honeycomb panel: a lightweight and sturdy industrial secret weapon!

- Aluminum Curtain Wall: Creating an Artistic Window for Modern Architecture

Industry dynamics

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum Ceiling: A Fashionable Choice for Modern Home Furnishings. Is Your Home Lacking It?

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum honeycomb panel: the secret of being as light as a feather and as solid as a rock

- Honeycomb aluminum panel: the 'invisible hero' of lightweight construction

Frequently asked questions

- What is the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What will be the future development trend of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

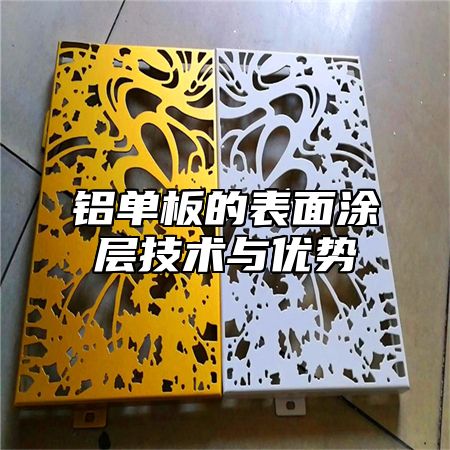

Surface coating technology and advantages of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 14:56:44

- Click:0

Aluminum veneer is a lightweight, high-strength, and corrosion-resistant new building material, and its surface coating technology is one of the important factors affecting its service life and decorative effect. The common surface coating technologies for aluminum veneer in the current market mainly include anodizing, electrophoretic coating, powder coating, etc. Below, we will provide a detailed introduction to the surface coating technology and advantages of aluminum veneer.

1、 Anodizing

Anodizing is a commonly used surface treatment technique for aluminum veneer, which improves its corrosion resistance and decorative properties by forming an oxide film on the surface of the aluminum veneer. The advantages of anodizing include:

1. Good corrosion resistance: The oxide film can effectively prevent aluminum veneer from being affected by corrosion and oxidation;

2. Good decorative performance: The oxide film has rich colors and textures, which can provide various decorative effects for aluminum veneer;

3. Higher hardness and wear resistance: Oxide film can improve the hardness and wear resistance of aluminum veneer, thereby extending its service life.

2、 Electrophoretic coating

Electrophoretic coating is an efficient surface treatment technology for aluminum veneer, which improves its decorative and corrosion resistance by electrolytically depositing a layer of coating on the surface of the aluminum veneer. The advantages of electrophoretic coating include:

1. Good decorative performance: Electrophoretic coating can provide multiple colors and textures to meet different decorative needs;

2. Good corrosion resistance: Electrophoretic coating can effectively prevent aluminum veneer from being affected by corrosion and oxidation;

3. High adhesion and wear resistance: Electrophoretic coating can improve the adhesion and wear resistance of aluminum veneer, thereby extending its service life.

3、 Powder coating

Powder coating is an environmentally friendly surface treatment technology for aluminum veneer, which improves its decorative and corrosion resistance by spraying a layer of powder on the surface of the aluminum veneer. The advantages of powder coating include:

1. Good decorative performance: Powder coating can provide multiple colors and textures to meet different decorative needs;

2. Good corrosion resistance: Powder coating can effectively prevent aluminum veneer from being affected by corrosion and oxidation;

3. Environmentally friendly: Powder coating does not contain harmful substances and does not pollute the environment.

The surface coating technology of aluminum veneer has a significant impact on its decorative effect and corrosion resistance. Coating technologies such as anodizing, electrophoretic coating, and powder coating each have their own advantages and disadvantages, and can be selected according to specific needs and requirements.

Customer service QQ

Customer service QQ