Industry information

Company News

- Honeycomb aluminum plate: a lightweight choice, a new chapter in innovative materials

- The magical charm of aluminum honeycomb panels: the perfect combination of lightweight and strength

- Honeycomb aluminum plate: a perfect fusion of lightness and sturdiness

- Aluminum veneer customization, creating a new trend of personalized space

- Honeycomb aluminum plate: the technological secret behind its lightweight design

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer is a perfect combination of affordable price, quality, and design

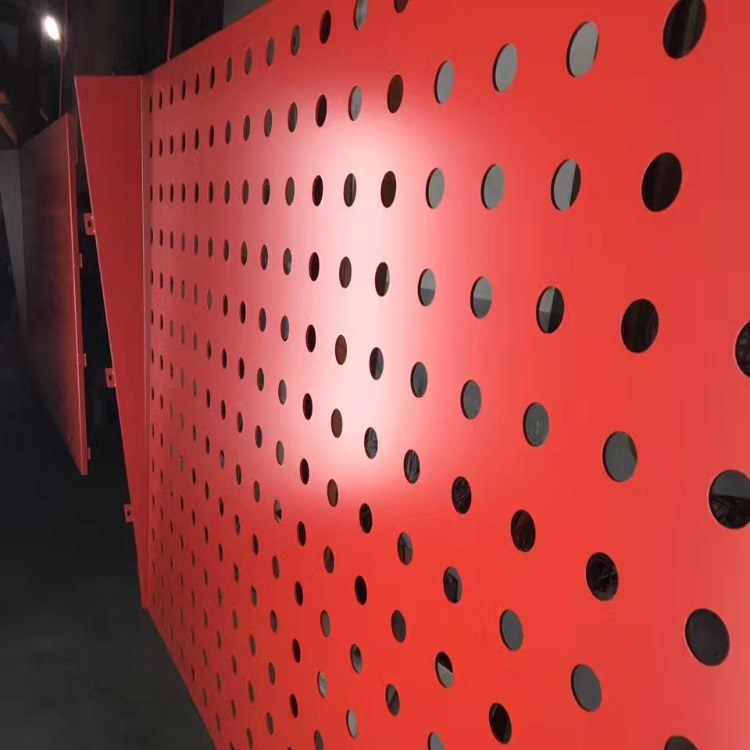

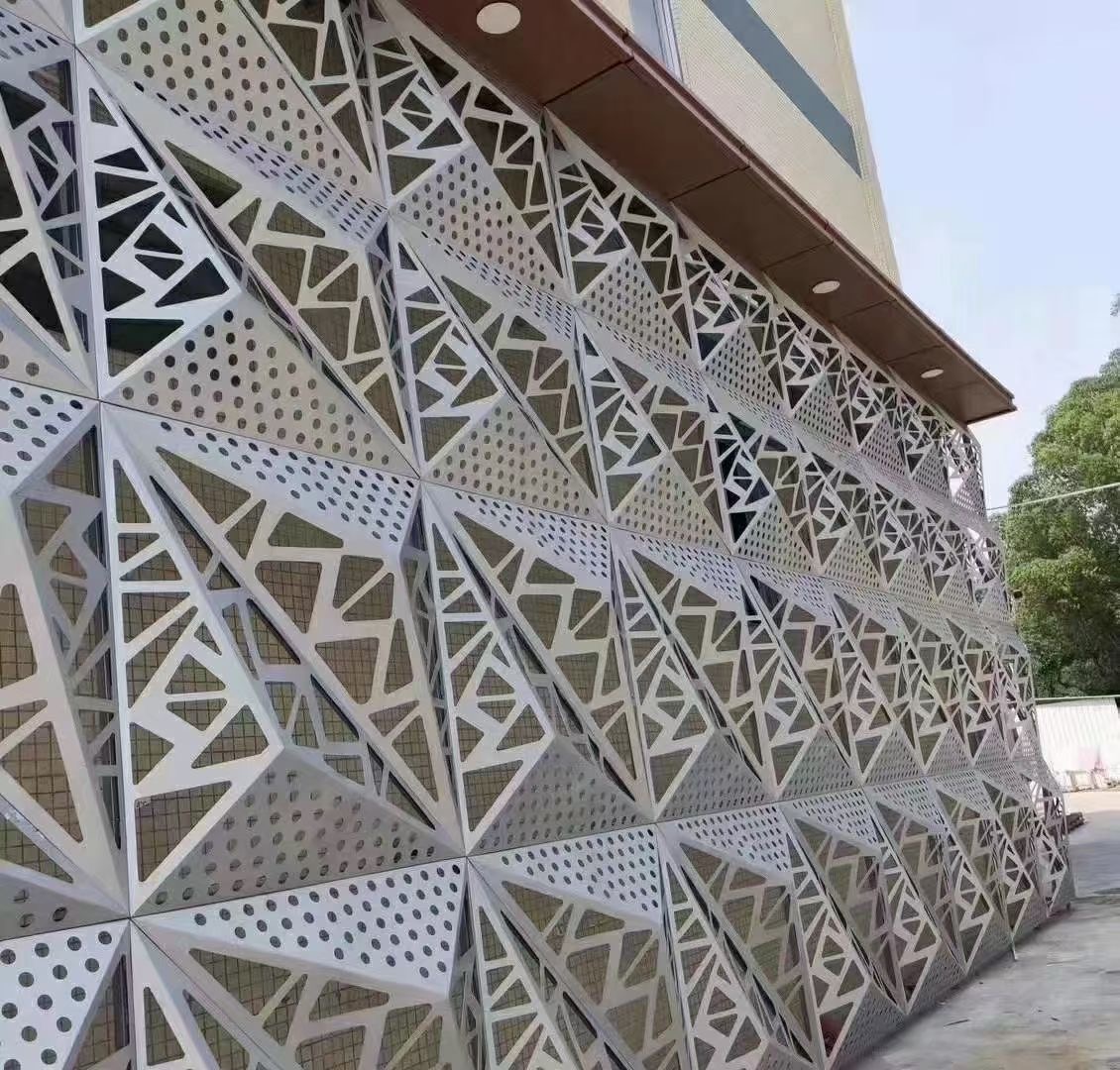

- Application and Innovation of Punching Process for 2.0mm Aluminum Veneer

- The new darling of the 1.5mm hollow aluminum veneer furniture industry

- High quality aluminum material manufacturing waves 3mm aluminum veneer brings longer protection and beauty to buildings

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the market demand for aluminum veneer?

- What are the main uses of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the environmental performance of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 04:22:03

- Click:0

Aluminum veneer, as a common building material, has advantages such as lightweight, corrosion resistance, and easy processing. Aluminum veneer also has good environmental performance, which can effectively reduce energy consumption and environmental pollution. Below, we will provide a detailed introduction on how to improve the environmental performance of aluminum veneer.

1、 Using high-quality raw materials

The environmental performance of aluminum veneer is closely related to the quality of its raw materials. When producing aluminum veneer, high-quality aluminum alloy sheets and surface treatment materials should be selected to ensure that they meet environmental requirements. Attention should also be paid to the sources and procurement channels of raw materials to avoid negative impacts on the environment.

2、 Optimize production process

The production process of aluminum veneer also has a certain impact on its environmental performance. In order to improve the environmental performance of aluminum veneer, some optimized production process methods can be adopted, such as roll forming, spraying, anodizing, etc. These methods can reduce energy consumption and waste emissions, thereby improving the environmental performance of aluminum veneer.

3、 Strengthen equipment maintenance and management

The production of aluminum veneer requires the use of various equipment, such as roller presses, spraying equipment, anodizing equipment, etc. The maintenance and management of these devices also have a significant impact on their environmental performance. In the production process, it is necessary to strengthen the maintenance and management of equipment, timely replace severely worn parts, ensure the normal operation of equipment, and reduce energy consumption and waste emissions.

4、 Strengthen waste management and recycling

During the production process of aluminum veneer, some waste materials are generated, such as wastewater, exhaust gas, and waste residue. If these wastes are not treated and recycled, they will cause pollution to the environment and waste resources. In the production process, it is necessary to strengthen the treatment and recycling of waste, adopt scientific treatment methods and technological means, and transform waste into reusable resources.

5、 Strengthen employee environmental awareness training

The production of aluminum veneer requires cooperation and collaboration in multiple stages, and employees in each stage should have a certain level of environmental awareness and skills. In the production process, it is necessary to strengthen the training of employees' environmental awareness, improve their understanding and importance of environmental protection, and enhance their sense of responsibility and mission.

Improving the environmental performance of aluminum veneer requires starting from multiple aspects, including using high-quality raw materials, optimizing production processes, strengthening equipment maintenance and management, enhancing waste disposal and recycling, and strengthening employee environmental awareness training. Only by comprehensively strengthening these aspects of work can we truly achieve the environmental protection goals of aluminum veneer and contribute to the cause of environmental protection.

Customer service QQ

Customer service QQ