Industry information

Company News

- Aluminum veneer: the new aesthetic favorite of modern architecture, revealing its unique charm!

- Honeycomb aluminum plate: the secret behind lightness

- Aluminum curtain wall, the fashionable coat of modern architecture

- Aluminum ceiling, creating a new fashion for modern home decor

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer: the "invisible armor" of modern architecture

- Aluminum veneer: the code of "silver fashion" in modern architecture

- Aluminum veneer is not just the new favorite of building materials

- Aluminum ceiling new trend: the beauty of light luxury lies in the details

- Aluminum curtain wall, the "fashionable coat" of modern architecture

Frequently asked questions

- How to increase the market demand for aluminum veneer?

- What is the market demand for aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Does the production process of aluminum veneer save energy?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 23:34:30

- Click:0

Aluminum veneer, as a new type of exterior wall decoration material, has excellent energy-saving and environmental protection performance. Whether its production process saves energy is one of the important indicators for evaluating its energy-saving and environmental performance. Let's take a detailed look at whether the production process of aluminum veneer saves energy.

1、 Raw material selection

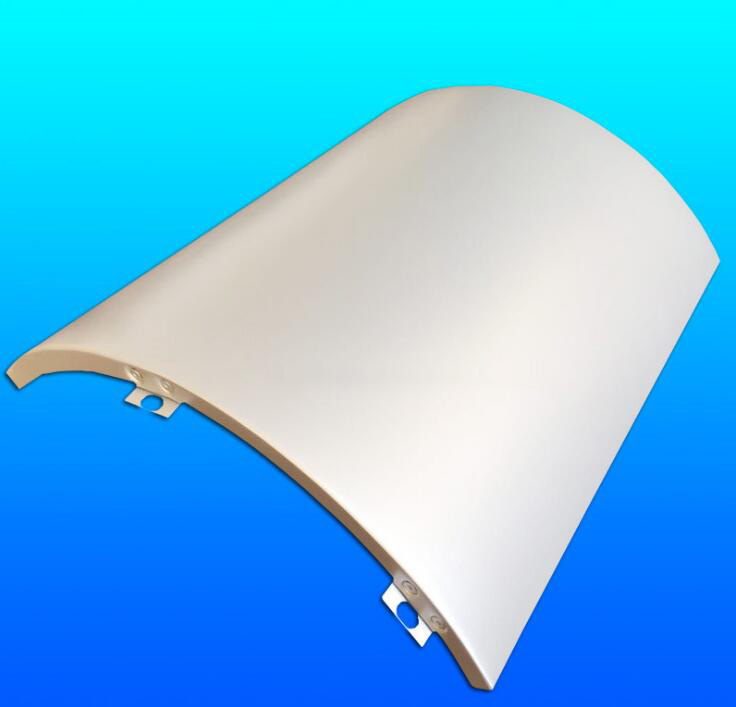

The selection of raw materials in the production process of aluminum veneer has a certain impact on its energy-saving and environmental performance. At present, the main raw materials for aluminum veneer are aluminum and surface treatment materials. Compared to traditional building materials, aluminum veneer has better recyclability and renewability, which can reduce resource waste and environmental pollution. In the selection of raw materials, it is necessary to consider their energy-saving and environmental performance, and choose raw materials that meet environmental requirements and sustainability.

2、 Production process

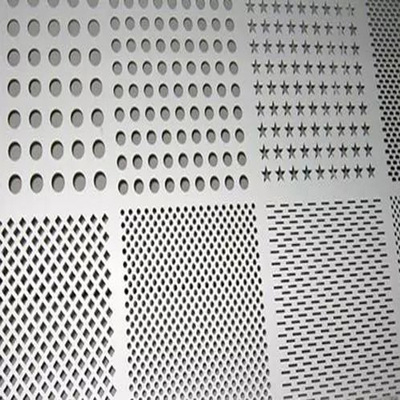

In the production process of aluminum veneer, the production process is also one of the important factors affecting its energy-saving and environmental performance. At present, the production process of aluminum veneer mainly includes processes such as extrusion molding and surface treatment. Extrusion molding is one of the key processes in the production of aluminum veneer and also one of the high energy consuming processes. In order to reduce energy consumption, advanced production processes and technological means need to be adopted, such as optimizing the structure of the extruder, adjusting extrusion parameters, etc., to improve production efficiency and reduce energy consumption. Surface treatment is also one of the important factors affecting the energy-saving and environmental performance of aluminum veneer. It is necessary to choose surface treatment materials and processes that meet environmental requirements to reduce the impact on the environment.

3、 Energy consumption

In the production process of aluminum veneer, energy consumption is also an important indicator for evaluating its energy-saving and environmental performance. The production process of aluminum veneer requires a large amount of electricity and heat energy, such as extruders, ovens, and other equipment. A series of measures need to be taken in the production process to reduce energy consumption, such as using high-efficiency energy-saving equipment, optimizing production processes, etc. We also need to strengthen energy management and improve energy utilization efficiency to achieve the goal of energy conservation and emission reduction.

4、 Conclusion

The production process of aluminum veneer can save energy to a certain extent. By selecting and applying aluminum veneer materials reasonably, it can bring more opportunities and possibilities for energy conservation and environmental protection to the construction industry. It is also necessary to select aluminum veneer products and service providers that are suitable for local characteristics based on actual situations and specific needs, in order to ensure the safety, stability, and aesthetics of buildings.

Customer service QQ

Customer service QQ