Industry information

Company News

- Customized aluminum veneer, a new choice for personalized space

- Aluminum curtain wall: a new trend in architecture, stay ahead of future trends!

- Aluminum curtain wall, the fashionable coat of modern architecture

- The Beauty of Aluminum Curtain: The Fashionable Coat of Modern Architecture

- Aluminum veneer customization, creating a new trend of personalized space!

Industry dynamics

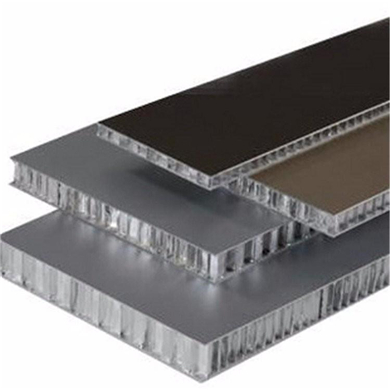

- Honeycomb aluminum plate: a lightweight choice, the secret weapon of modern architecture

- The Beauty of Aluminum Ceiling: Simplicity Reveals Luxury

- Transportation and logistics of aluminum veneer to ensure safe and timely arrival of goods

- Aluminum Curtain Wall: The Beauty of Architecture, the Interpretation of Aluminum

- Rust prevention performance and long-term protection of aluminum veneer

Frequently asked questions

- What is the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What is the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and technical characteristics of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-11 11:20:04

- Click:0

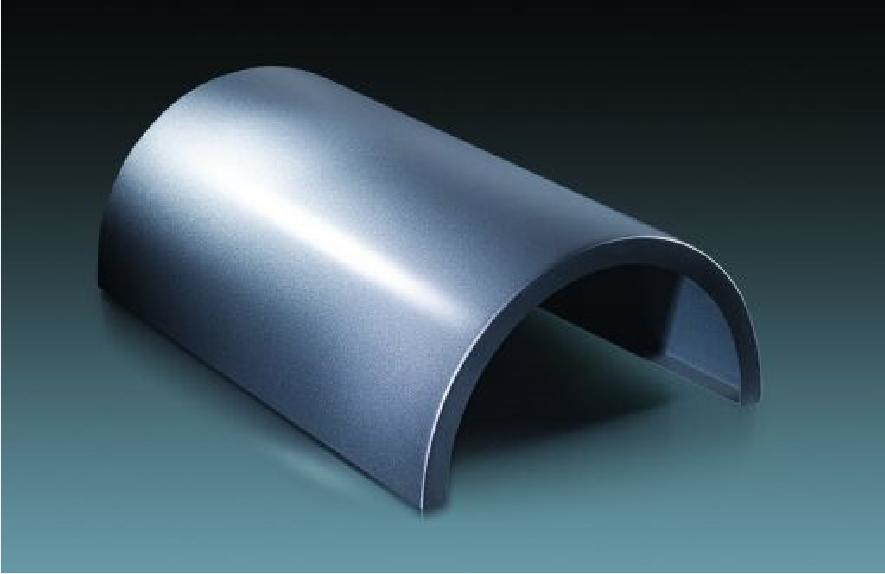

Aluminum veneer is a lightweight and high-strength building material, and its manufacturing process and technical characteristics are also one of the important reasons why it can be widely used in the field of construction. This article will provide a detailed introduction to the manufacturing process and technical characteristics of aluminum veneer.

1、 Production process

1. Raw material preparation

The main raw material for aluminum veneer is aluminum alloy sheet. Before production, strict screening and testing of raw materials are required to ensure that they meet product quality requirements.

1. Cutting and processing

The size and shape of aluminum veneer need to be customized according to actual needs, so cutting and processing are required during the production process. Cutting and processing can be carried out using equipment such as CNC machine tools or laser cutting machines to ensure dimensional accuracy and surface smoothness.

1. Welding processing

The joints of aluminum veneer need to be welded to ensure its strength and stability. The commonly used welding methods are pressure welding and spot welding, among which pressure welding is the more commonly used and reliable method.

1. Surface treatment

The surface of aluminum veneer needs to be treated to improve its aesthetics and corrosion resistance. Common surface treatment methods include anodizing, spraying, electrophoretic coating, etc. These processing methods can form a protective film on the surface of aluminum veneer, thereby improving its corrosion resistance and oxidation resistance.

2、 Technical features

1. Lightweight and high-strength

Aluminum veneer has low density, light weight, and high strength and rigidity, which can meet various load-bearing requirements of buildings.

1. Good sound insulation effect

Aluminum veneer has good sound insulation effect, which can effectively reduce the impact of noise on indoor environment. This is particularly important for public places such as shopping malls, hotels, etc.

1. Easy to process and install

Aluminum veneer has good plasticity and processability, and can be customized and processed according to actual needs. The installation of aluminum veneer is also relatively simple and convenient, and can be installed by dry hanging or wet hanging methods.

1. Environmental protection and energy conservation

Customer service QQ

Customer service QQ