Industry information

Company News

- Aluminum honeycomb panel: a lightweight 'magician' in the construction industry

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum Ceiling: The Shining Star of Metal in Modern Architecture

- The secret of honeycomb aluminum plate: the technological mystery behind its lightness

- The wonderful world of honeycomb aluminum plate: the secret behind its lightness

Industry dynamics

- The new trend of aluminum ceiling reveals the "beauty of the sky" in modern architecture

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

- Aluminum curtain wall: the new darling of architecture, the perfect combination of fashion and practicality!

- Application and advantages of twisted 2.5mm aluminum veneer in architectural decoration

- Aluminum honeycomb panel: the secret of being as light as a feather and as solid as a rock

Frequently asked questions

- What will be the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

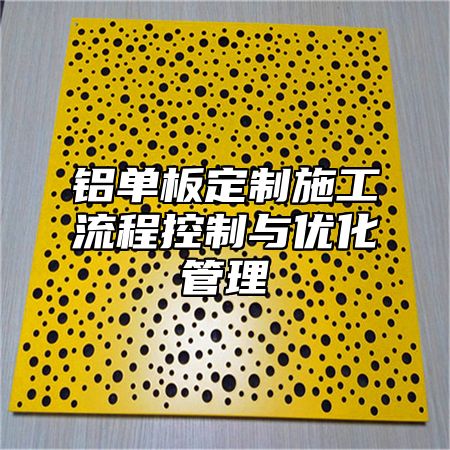

Control and optimization management of customized construction process for aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-18 18:26:52

- Click:0

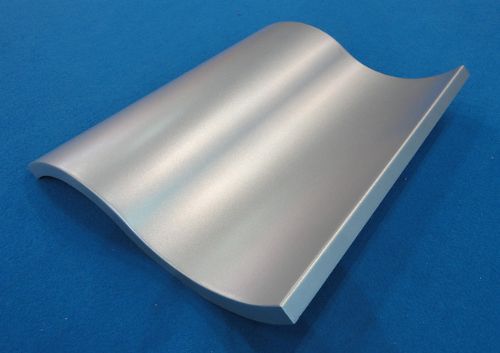

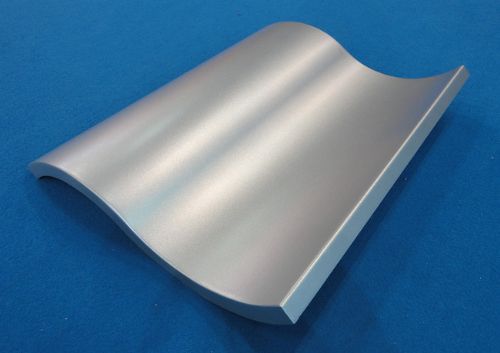

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, corrosion resistance, and easy processing, and has been widely used in the field of building decoration. The construction process control and optimization management of customized aluminum veneer is one of the key factors affecting product quality and effectiveness. Below, we will provide a detailed introduction to the control and optimization management of the customized construction process for aluminum veneer.

1、 Analysis of Construction Process Control

1. Preparation work before construction

Before the construction of aluminum veneer, it is necessary to clean and tidy up the construction site, and prepare the necessary tools and equipment. Training and guidance are also needed for construction personnel to ensure the smooth progress of the construction process.

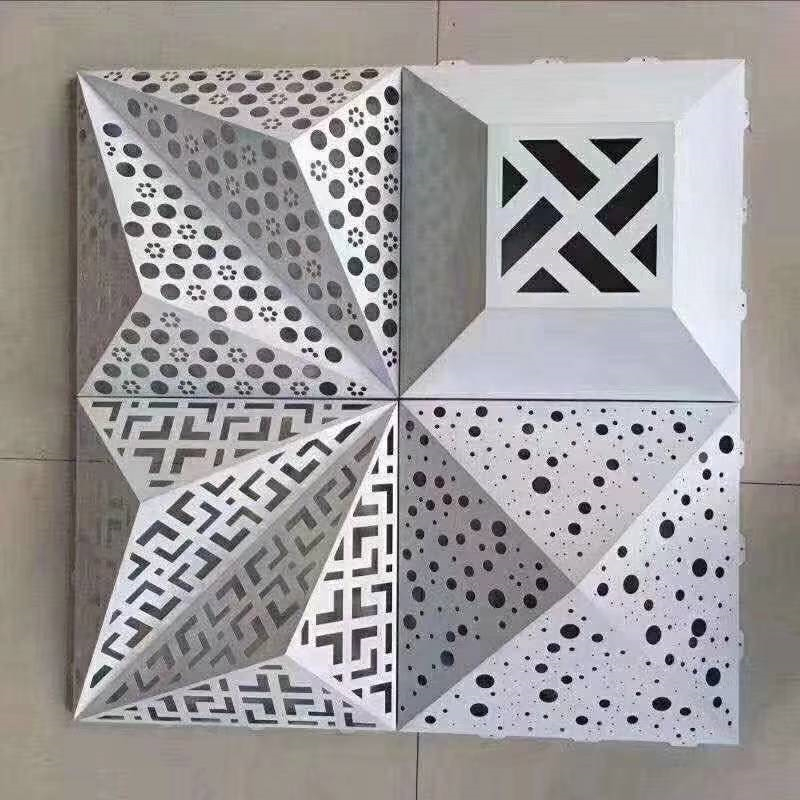

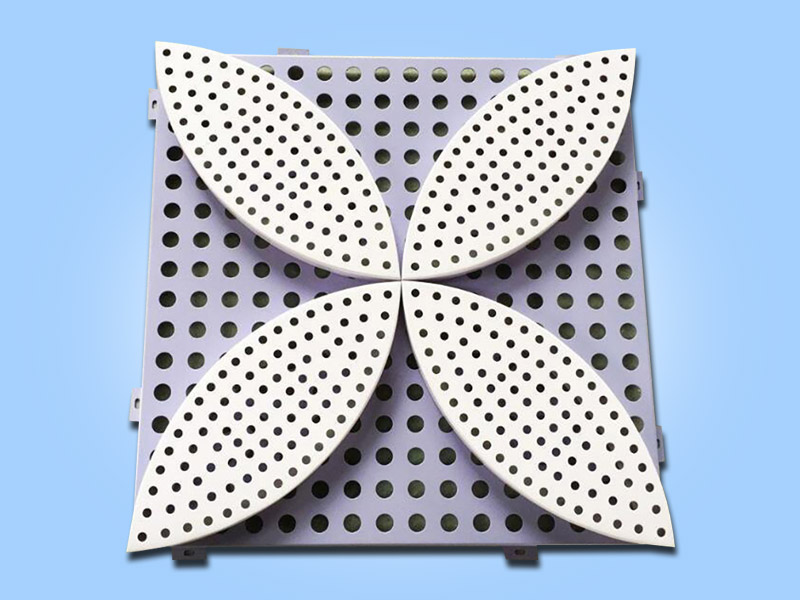

2. Installation method of aluminum veneer

The installation methods of aluminum veneer include dry hanging and wet pasting. The dry hanging installation method has the advantages of convenient installation and good stability, but it requires the use of auxiliary materials such as embedded parts and keel; The wet patch installation method requires the use of special adhesives and sealants, which have the advantages of simple installation and low cost. During construction, it is necessary to choose a suitable installation method based on the actual situation.

3. Safety measures during the construction process

During the construction process of aluminum veneer, safety issues need to be taken into account, such as preventing falling from heights and preventing electric shock. Attention should also be paid to environmental hygiene and fire prevention issues at the construction site.

2、 Optimize management analysis

1. Construction progress management

Strict management of the construction progress is required during the construction process of aluminum veneer to ensure the reasonable arrangement of the construction period and the smooth progress of the project. Management of construction progress can be achieved by developing detailed construction plans and schedules.

2. Quality management

Strict control and management of construction quality are required during the construction process of aluminum veneer to improve product stability and reliability. The management of construction quality can be achieved by establishing a sound quality management system and formulating corresponding quality standards.

3. Safety management

During the construction process of aluminum veneer, safety issues need to be taken into account, such as preventing falling from heights and preventing electric shock. Management of construction safety can be achieved through strengthening personnel training and management, establishing safety management systems, and other means.

3、 Implementation suggestions

1. Strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance the competitiveness and profitability of enterprises.

2. Establish a comprehensive quality management system to monitor and manage the entire production process, in order to improve product stability and reliability.

3. Strengthen personnel training and management, improve employees' technical level and work quality, to ensure the smooth progress of the production process.

4. Strengthen cooperation and communication with suppliers, establish long-term stable cooperative relationships to ensure the quality of raw materials and the stability of supply.

5. Strengthen communication and interaction with customers, understand their needs and expectations, and provide more comprehensive and objective selection criteria and service support.

4、 Conclusion and Prospect

Based on the suggestions for controlling and optimizing the construction process mentioned above, it can be seen that controlling and optimizing the construction process of customized aluminum veneer is very important. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen comparative research with other materials to provide consumers with more comprehensive and objective selection criteria. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is also necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ