Corporate News

Company News

- Aluminum honeycomb panel: the 'hidden hero' of the construction industry!

- Aluminum Curtain Wall: The Aesthetic Choice of Modern Architecture

- Aluminum curtain wall: the fashionable "coat" of modern architecture

- The secret of aluminum honeycomb panel: the technological power behind its lightweight design

- The secret of aluminum honeycomb panel: the technological power behind its lightness

Industry dynamics

- Aluminum ceiling, revealing the fashionable choice of modern home!

- Aluminum honeycomb panel: the "light magician" of the construction industry

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum ceiling, a fashionable choice for creating modern spaces

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the market demand for aluminum veneer?

- How to increase the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production equipment and technological progress of aluminum veneer, and the development trend of automated production

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 08:29:38

- Click:0

The production equipment and technological progress of aluminum veneer, and the development trend of automated production

Abstract: This article will elaborate on the production equipment and technological progress of aluminum veneer, as well as the development trend of automation production from four aspects. Firstly, introduce the current situation and development trend of production equipment for aluminum veneer; Secondly, explore the impact of technological progress on the production of aluminum veneer; Then, analyze the significance of automated production for the aluminum veneer industry; Finally, summarize the viewpoints and conclusions of this article.

1、 The current situation and development trend of production equipment for aluminum veneer

1. Traditional production equipment status

At present, the production of aluminum veneer mainly relies on traditional mechanical processing equipment, such as shearing machines, bending machines, punching machines, etc. The operation of these devices requires a large amount of manual participation, with low efficiency and long production cycles.

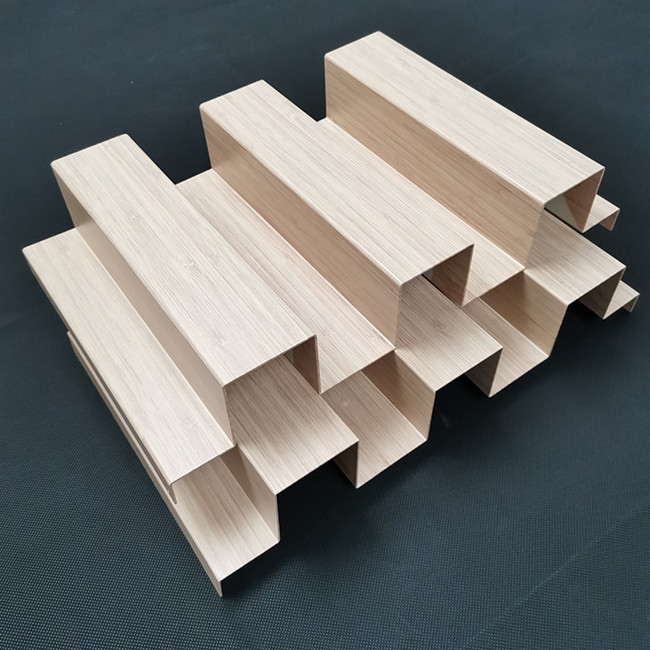

2. The emergence of new production equipment

With the advancement of technology, new production equipment has begun to be applied in the aluminum veneer industry, such as CNC shearing machines, automated bending machines, laser cutting machines, etc. These devices have a high degree of automation and intelligence, greatly improving production efficiency and product quality.

3. Future Development Trends

With the continuous development of artificial intelligence, machine learning, and big data technology, it is expected that the production equipment of aluminum veneer will move towards a more intelligent and automated direction. Artificial intelligence technology can achieve autonomous adjustment and optimization of devices, improving production efficiency and product quality.

2、 The impact of technological progress on aluminum veneer production

1. Material research and innovation

With the advancement of technology, new aluminum alloy materials are constantly being developed and applied in the production of aluminum veneers. These new materials have better corrosion resistance, strength, and toughness, which can meet the needs of different environments.

2. Surface treatment technology

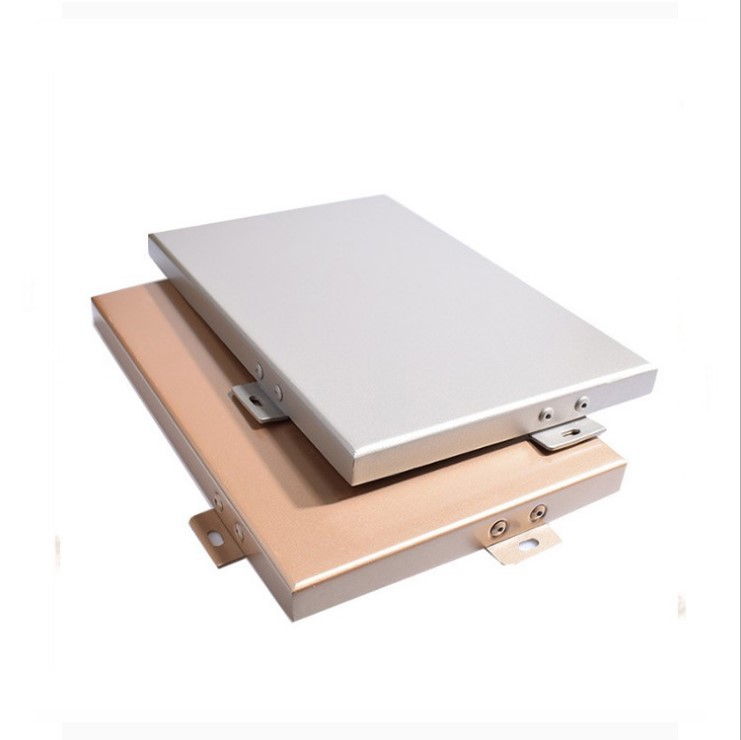

Surface treatment plays a crucial role in the quality and appearance of aluminum veneer. With the advancement of technology, new surface treatment techniques continue to emerge, such as anodizing, spraying, etc., which can achieve higher corrosion resistance and decorative effects.

3. Digital Design and Production

The emergence of digital design and production technology has made the production process of aluminum veneer more efficient and precise. Through computer-aided design and intelligent manufacturing technology, complex shaped aluminum veneer production can be achieved, improving product accuracy and consistency.

3、 The significance of automated production for the aluminum veneer industry

1. Improve production efficiency and product quality

Automated production can reduce manual errors and labor intensity, thereby improving production efficiency and product quality. The accuracy and stability of automation equipment can ensure the consistency of product size and surface quality.

2. Reduce production costs and resource consumption

Automated production can significantly reduce labor costs and minimize resource waste. Automated equipment can more accurately control the use of materials and energy, improving resource utilization efficiency.

3. Meet personalized customization needs

With the continuous changes in market demand, the demand for personalized customization is increasing. Automated production can flexibly adjust the production process, quickly respond to customer needs, and meet customized aluminum veneer of various shapes and specifications.

4、 Summary

From the above explanation, we can see that the production equipment and technological progress of aluminum veneer, as well as the development trend of automation production, are of great significance to the development of the industry. With the continuous advancement of technology, the aluminum veneer industry will usher in a more intelligent, efficient, and personalized production mode.

Therefore, enterprises should actively adopt new production equipment, pay attention to technological progress, and invest in the research and application of automated production to maintain market competitiveness and meet constantly changing demands.

- Previous Page: None

- Next page:The production equipment and technological progress of aluminum veneer, and the trend of automated production

Customer service QQ

Customer service QQ