Corporate News

Company News

- Aluminum curtain wall, the fashionable coat of modern architecture

- Aluminum curtain wall: not just an exterior wall, but also a fusion of art and technology

- Aluminum veneer: not only a building material, but also the soul of architecture

- Customized aluminum veneer, creating personalized space and new fashion

- The magical world of honeycomb aluminum plate: the perfect fusion of lightweight and sturdy

Industry dynamics

- Creating Future Technology Buildings with Hyperbolic Aluminum Veneers

- How can aluminum veneer enhance the visual appeal of buildings?

- Honeycomb aluminum plate: a perfect combination of lightweight and sturdy

- Innovative technology applied to decorative roller coated aluminum veneer

- Aluminum curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- What are the main uses of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production equipment and technological progress of aluminum veneer, and the trend of automated production

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 10:49:03

- Click:0

The production equipment and technological progress of aluminum veneer, and the trend of automated production

Abstract: With the rapid development of technology, the production equipment and technology of aluminum veneer are constantly improving, and automated production has become an undeniable trend. This article will elaborate on the progress of aluminum veneer production equipment and technology, as well as the trend of automated production from four aspects.

1、 Equipment automation

1. Introduction of automation equipment

With the rapid development of artificial intelligence and machine learning, automated equipment has been widely used in the production process of aluminum veneer. Traditional manual operations are gradually being replaced by automated equipment, improving production efficiency and quality stability.

2. Intelligent control system

All aspects of aluminum veneer production can be automated and managed through intelligent control systems, from raw material procurement to finished product packaging, which can be monitored and controlled throughout the entire process. This not only improves the accuracy and consistency of production, but also reduces human intervention, avoiding potential errors and delays.

3. Automated testing and quality control

Automated equipment can perform real-time detection and quality control, monitoring and adjusting key parameters such as size and surface quality of aluminum veneer. Through automatic feedback and adaptive control, problems in production can be quickly solved and product quality can be improved.

2、 Digital Production Management

1. Data collection and analysis

With the help of sensors and data acquisition devices, various data during the production process of aluminum veneer can be accurately recorded. Through data analysis and processing, optimization and improvement of the production process can be achieved, improving production efficiency and resource utilization.

2. Remote monitoring and management

Using the Internet and remote monitoring technology, production management personnel can remotely monitor the operation status and production of the aluminum veneer production line at any time. Once abnormalities or malfunctions occur, timely measures can be taken to handle them, avoiding production interruptions and quality issues.

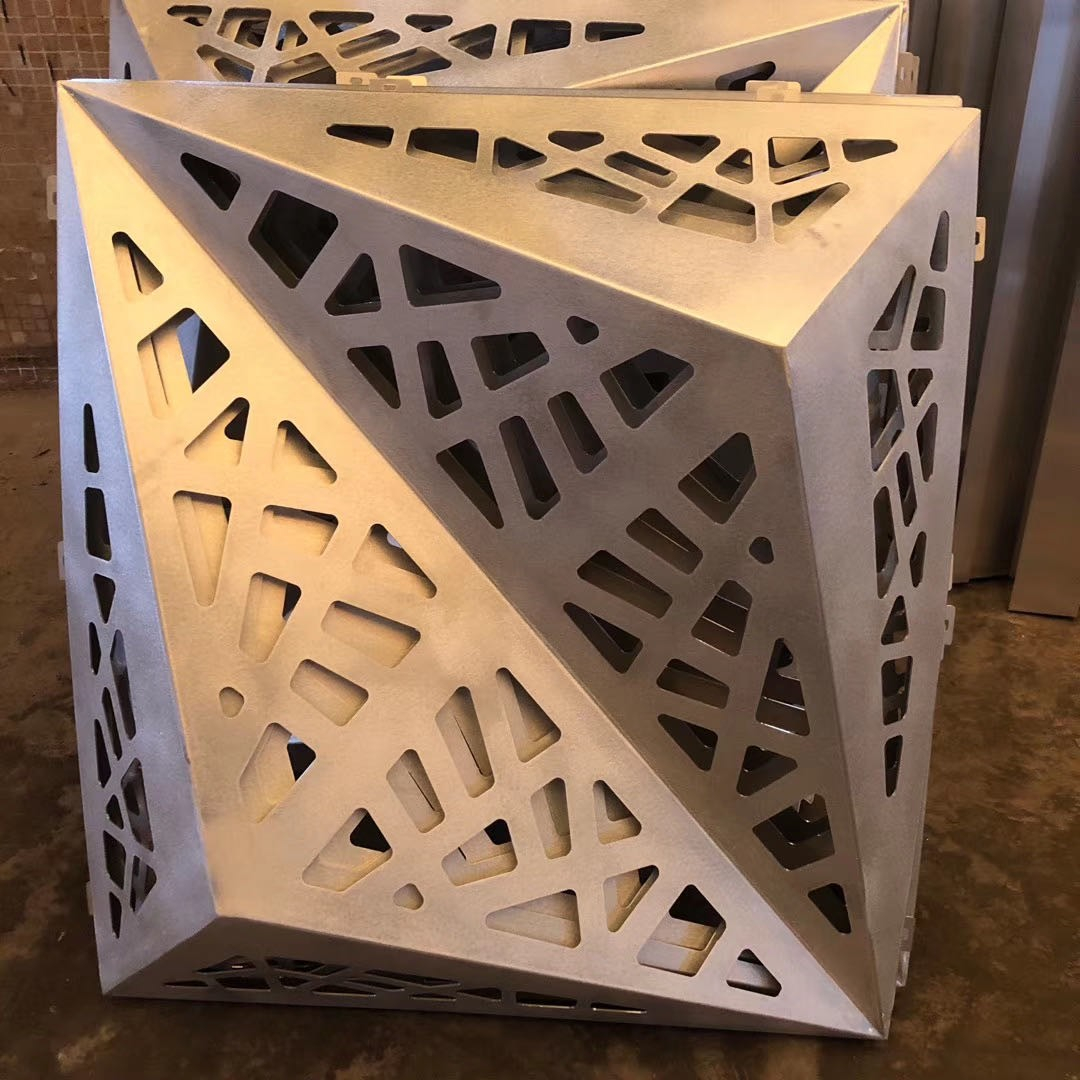

3. Intelligent manufacturing and customized production

Digital production management can achieve intelligent manufacturing and customized production, personalized customization according to customer needs, and provide more accurate and market demand compliant aluminum veneer products. This not only increases the competitiveness of the product, but also enhances customer satisfaction.

3、 Material and process improvement

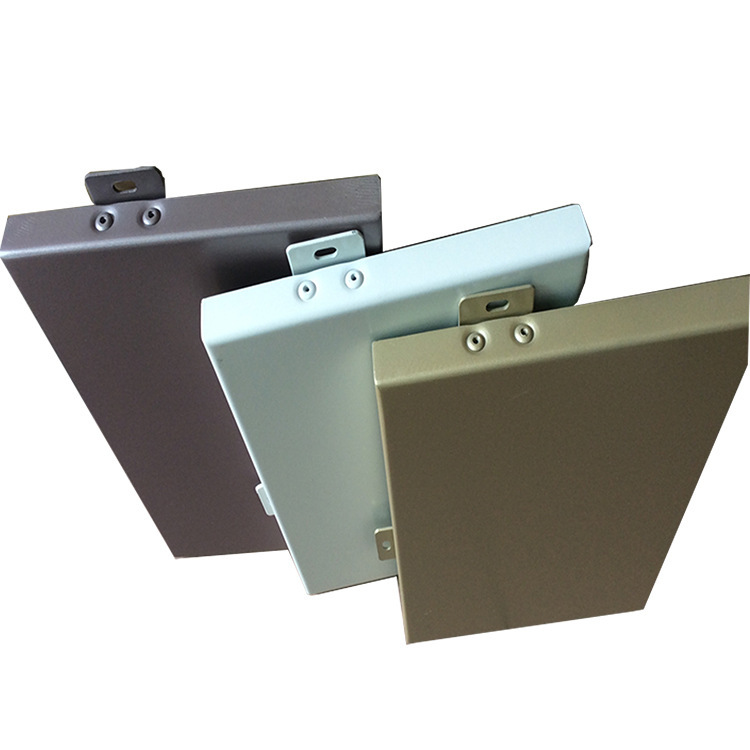

1. Application of new materials

With the advancement of technology, new high-strength and corrosion-resistant aluminum alloy materials are widely used in the production of aluminum veneer. These materials not only have excellent physical properties, but also can reduce costs and improve product quality.

2. Advanced processing technology

The production process of aluminum veneer is also constantly innovating and improving, such as using advanced rolling, stretching, bending and other processes to improve the formability and processing efficiency of materials, while reducing waste and energy consumption.

3. Enhancement of environmental awareness

In the production process of aluminum veneer, there is an increasing demand for environmental protection. The new processes and equipment have effectively controlled the discharge of wastewater and exhaust gas, improved the recycling rate of materials, and achieved sustainable utilization of resources.

4、 Intelligent production and application of artificial intelligence

1. Robot applications

In the production process of aluminum veneer, robots can undertake many repetitive, dangerous, and precise tasks. For example, processes such as polishing and spraying can be achieved through robots, improving work efficiency and safety.

2. Internet of Things technology

By utilizing IoT technology, various devices and systems on the aluminum veneer production line can be interconnected, share information and data, and achieve automation and optimization of the production process. Through intelligent scheduling and resource management, maximum production efficiency can be achieved.

3. Artificial intelligence optimization

With the help of artificial intelligence technology, some complex problems in aluminum veneer production can be quickly solved. For example, through machine learning algorithms, production plans can be optimized, product quality can be predicted, and adjustments can be made based on real-time data to improve production efficiency and product quality.

5、 Summary:

The production equipment and technological progress of aluminum veneer have made automation production an irreversible trend. Equipment automation, digital production management, material and process improvement, as well as intelligent production and artificial intelligence applications, will all promote the development of aluminum veneer production towards higher efficiency, intelligence, and environmental protection. With further breakthroughs and innovations in technology, the aluminum veneer industry will usher in a better future.

Customer service QQ

Customer service QQ