Industry information

Company News

- The Secret World of Honeycomb Aluminum Plate: The Perfect Fusion of Lightness and Strength

- Honeycomb aluminum plate: the industrial secret behind lightness

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum Curtain Wall: The 'Fashion Coat' of the Architecture Industry

- Aluminum ceiling, poetic embellishment of modern space

Industry dynamics

- Honeycomb aluminum plate: a perfect combination of lightweight and sturdy

- Aluminum veneer is safe and durable

- The charm of honeycomb aluminum plate: the technological secret behind its lightness

- The 'secret' of honeycomb aluminum plate: as light as a feather, as solid as a rock!

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How long is the service life of aluminum veneer?

- What are the characteristics of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Splicing and connection technology of aluminum veneer for curtain wall

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-16 14:59:40

- Click:0

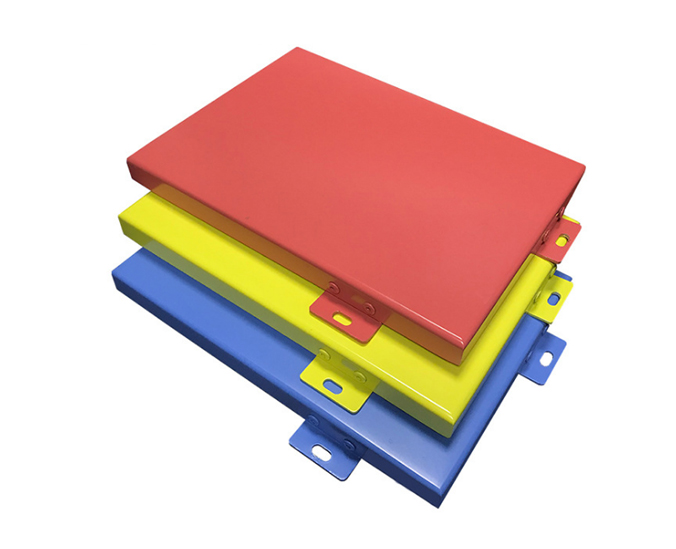

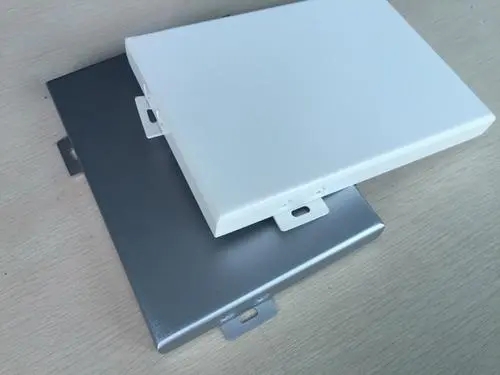

As a common building decoration material, the splicing and connection process of curtain wall aluminum veneer has a significant impact on the appearance and structure of buildings. Below is a detailed introduction to the splicing and connection process of curtain wall aluminum veneer.

1、 Splicing process

In terms of the splicing process of curtain wall aluminum veneer, it mainly involves the following aspects:

1. Welding technology: By using welding techniques such as arc welding and argon arc welding, the various parts of the curtain wall aluminum veneer are joined together to form a complete structure.

2. Adhesive technology: By using adhesive materials such as double-sided tape and silicone, the various parts of the curtain wall aluminum veneer are spliced together to form a complete structure.

3. Bolt connection technology: By using bolt connection, the various parts of the curtain wall aluminum veneer are spliced together to form a complete structure.

2、 Connection process

In terms of the connection process of curtain wall aluminum veneer, it mainly involves the following aspects:

1. Riveting technology: By using rivets to connect the various parts of the curtain wall aluminum veneer, a complete structure is formed.

2. Welding technology: By using welding techniques such as arc welding and argon arc welding, the various parts of the curtain wall aluminum veneer are connected to form a complete structure.

3. Bolt connection technology: By using bolt connection method, the various parts of the curtain wall aluminum veneer are connected to form a whole structure.

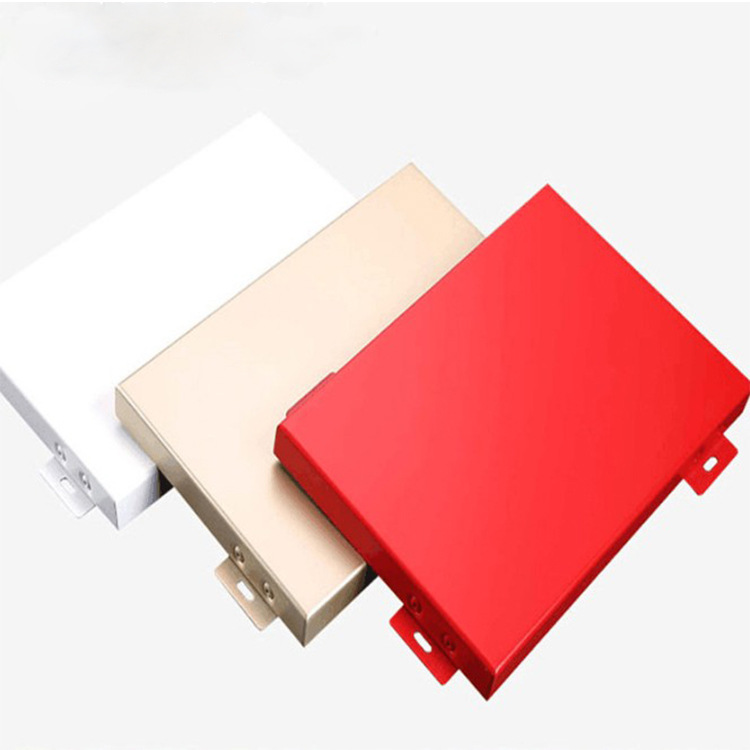

3、 Conclusion and Suggestions

When selecting and using curtain wall aluminum panels, attention should be paid to the considerations of splicing and connection processes to meet the requirements of building appearance and structure. It is also necessary to pay attention to the selection and control of material quality, process level, and other aspects to ensure the quality and effect of the curtain wall aluminum veneer. For suppliers, they can provide higher quality curtain wall aluminum veneer products and services by continuously optimizing product design, strengthening technological research and development, and meeting the needs of different customers. We also need to strengthen our awareness of environmental protection and responsibility, and actively promote the application and development of green environmental protection concepts in the curtain wall aluminum veneer industry.

Customer service QQ

Customer service QQ