Industry information

Company News

- Honeycomb aluminum plate: the secret of being as light as air and as strong as iron

- The production equipment and technological progress of aluminum veneer, and the trend of automated production

- The magnificent transformation of aluminum veneer: from ordinary to extraordinary

- Aluminum Curtain Wall: Creating an Artistic Window for Modern Architecture

- Aluminum Ceiling: The 'Sky Garden' of Modern Architecture

Industry dynamics

- Aluminum veneer customization, creating an artistic journey of personalized space

- Advantages of Aluminum Honeycomb Panel

- Aluminum curtain wall: the new darling of modern architecture and the environmental pioneer of energy conservation and emission reduction!

- Aluminum veneer customization, creating a new trend of personalized space

- What are the characteristics of aluminum veneer design?

Frequently asked questions

- How long is the service life of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the characteristics of aluminum veneer?

- What is the market demand for aluminum veneer?

- What are the main uses of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the technological power behind lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 20, 2025 13:48:40

- Click:0

You know what? In our daily lives, there is a magical type of board that is both lightweight and sturdy, and it is honeycomb aluminum plate. Does it sound a bit like material from science fiction novels? Don't worry, today we will talk about the technological power behind this lightness.

Let's talk about the origin of honeycomb aluminum panels. It was born in the 1950s and is a product of the aerospace industry. At that time, engineers racked their brains to find new materials in order to reduce the weight of airplanes and improve flight efficiency. As a result, honeycomb structures emerged, and aluminum, as a representative of lightweight metals, became the best partner.

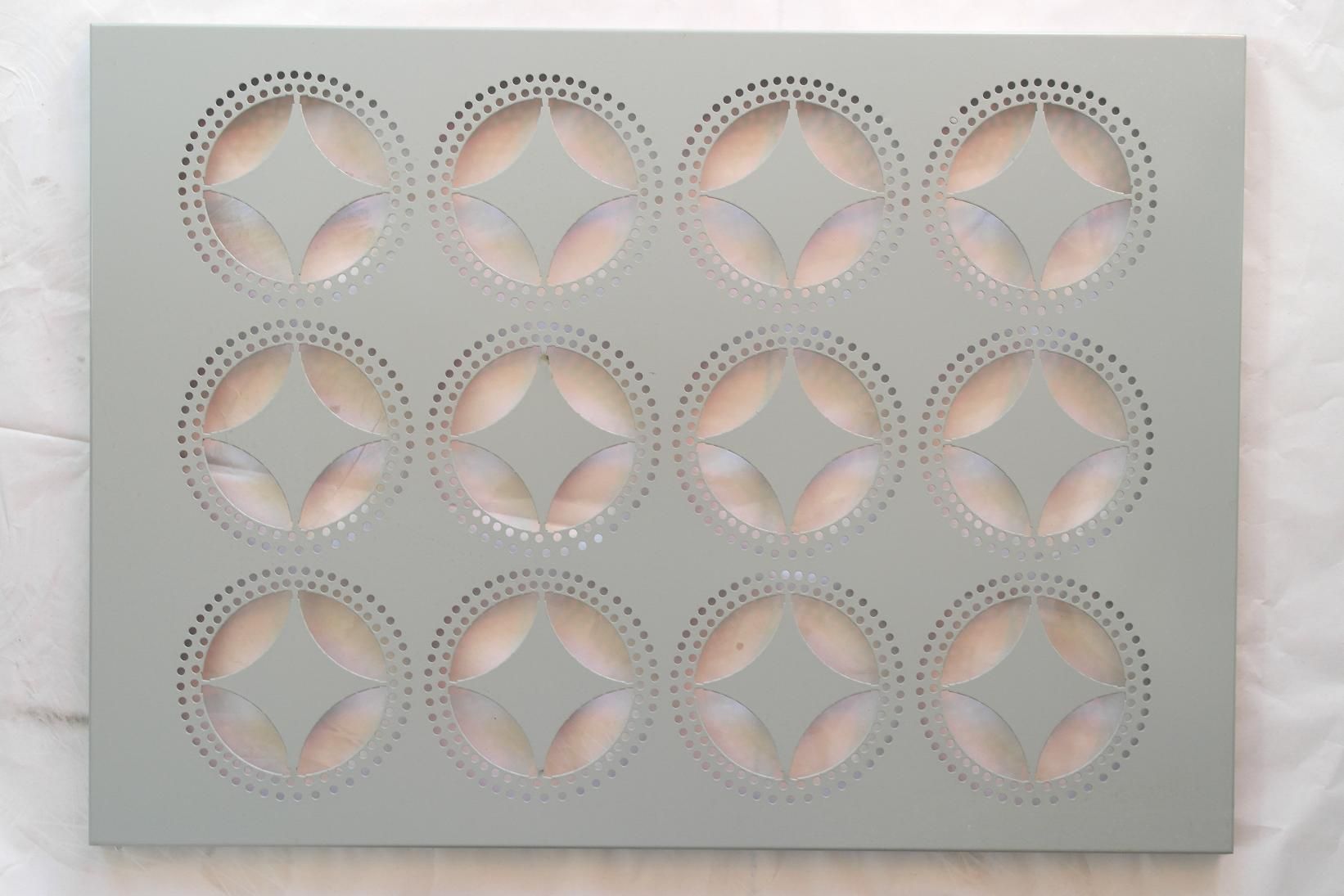

Honeycomb structure, as the name suggests, is composed of many interconnected hexagonal honeycomb units, just like a honeycomb. This structure can reduce weight while maintaining extremely high strength and rigidity. Honeycomb aluminum plate is as lightweight as feathers and as sturdy as rocks.

You may ask, besides aerospace, where else can such good materials be used? There are really quite a few! Honeycomb aluminum panels play an important role in building materials, automobile manufacturing, electronic products, and even sports equipment.

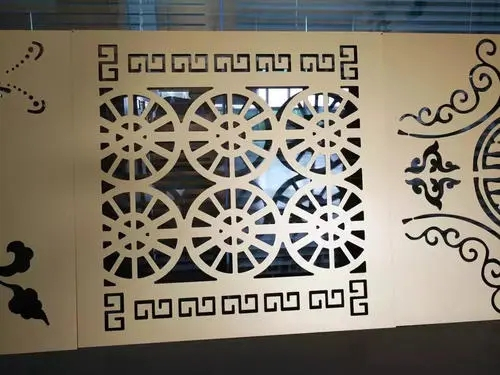

Let's talk about the field of architecture first. Honeycomb aluminum panels, as a new type of building material, have been widely used in curtain walls, interior decoration, and other high-rise buildings. Its lightness makes the building structure more lightweight, reduces the load on the foundation, has excellent insulation performance, and is also energy-saving and environmentally friendly.

Let's take a look at car manufacturing again. With the rise of new energy vehicles, the demand for lightweight and high-strength materials is increasing day by day. Honeycomb aluminum panels perfectly meet these requirements. In automobile manufacturing, it is used to manufacture engine covers, body structural components, etc., which not only reduces vehicle weight and improves fuel efficiency, but also enhances vehicle safety.

In terms of electronic products, honeycomb aluminum panels also play an important role. Honeycomb aluminum panels can be used for the casing of electronic devices such as mobile phones and computers. This material has good electromagnetic shielding performance and can effectively prevent electromagnetic radiation.

Sports equipment cannot be without honeycomb aluminum panels. Sports equipment such as badminton rackets and tennis rackets are made of honeycomb aluminum plates, which are lightweight and durable, and can also improve the competitive level of athletes.

Speaking of honeycomb aluminum sheet itself, it still has many unique features. It has good processing performance and can be cut, stamped, welded, etc., meeting the needs of different fields. Honeycomb aluminum plate also has excellent characteristics such as corrosion resistance, high temperature resistance, and electrical and thermal conductivity.

However, honeycomb aluminum panels also have their shortcomings. The cost is relatively high. Due to the complex production process and strict requirements for raw materials, the price of honeycomb aluminum plates is relatively expensive. Recycling and disposal are relatively difficult. Although honeycomb aluminum panels can be recycled and reused, the recycling process is relatively complex and has a certain impact on the environment.

Honeycomb aluminum plate, as a new type of material, has excellent performance and wide application prospects, making it the preferred choice in more fields in the future. And with the continuous development of technology, I believe these problems will also be solved.

Recalling my first encounter with honeycomb aluminum panels, it was in a university laboratory. At that time, when the teacher explained the honeycomb structure to us, I was surprised by the beauty of this material. Unexpectedly, many years later, honeycomb aluminum sheets have penetrated into every aspect of our lives.

Honeycomb aluminum plate, the technological power behind its lightness, is worth our in-depth understanding. It shows us the crystallization of human wisdom and fills us with anticipation for the future. Perhaps in the near future, we will discover more magical materials like honeycomb aluminum panels, bringing more surprises to our lives. Let's look forward to it together!

Customer service QQ

Customer service QQ