Industry information

Company News

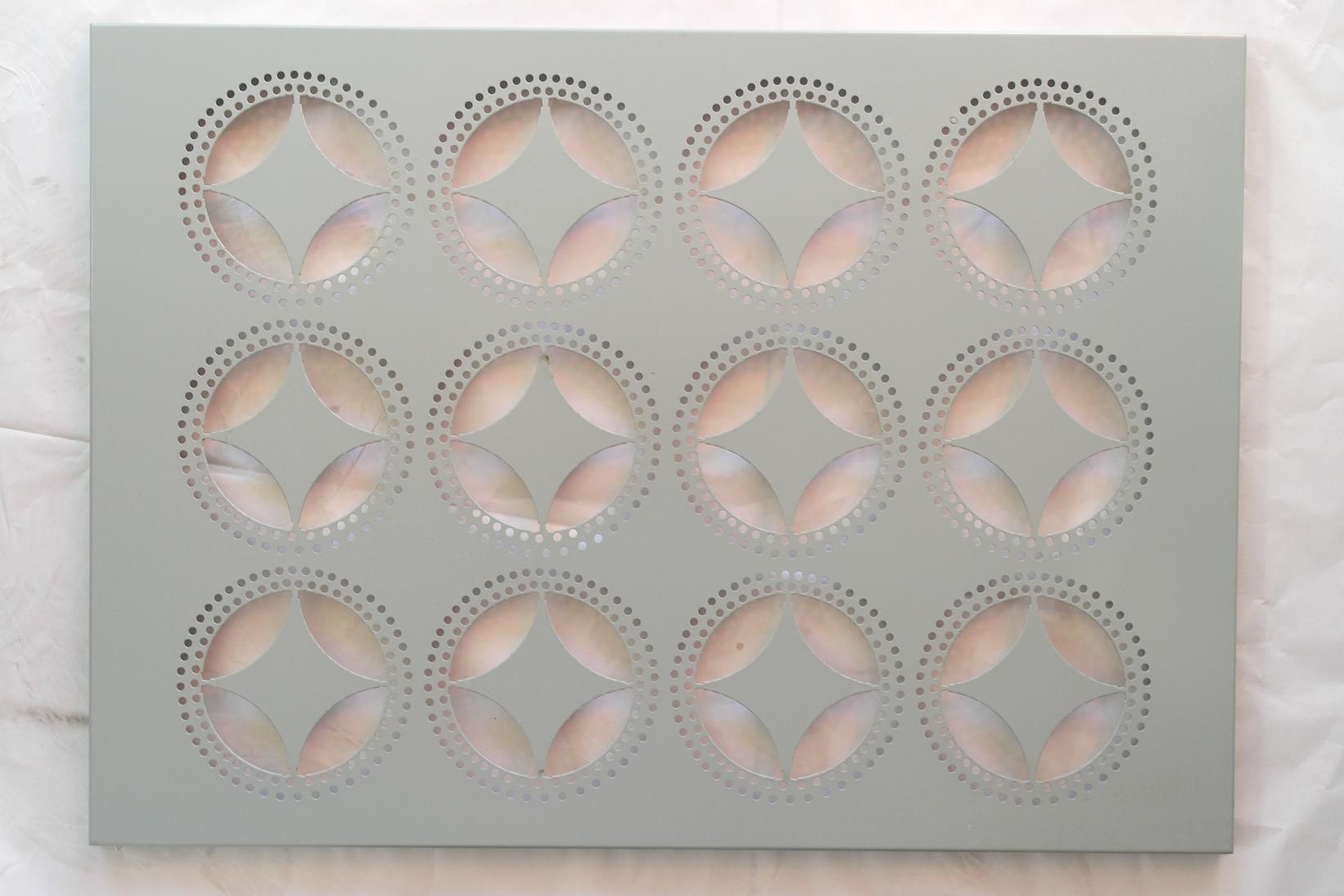

- Aluminum veneer customization, creating a new trend of personalized space

- The wonderful world of aluminum honeycomb panels: the new favorite of lightweight and sturdy panels

- Aluminum veneer customization: an artistic journey to create personalized spaces

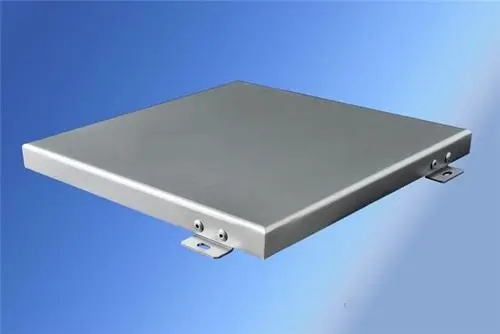

- Aluminum Ceiling: The Shining Star of Metal in Modern Architecture

- Aluminum curtain wall, a magnificent turn in architectural aesthetics

Industry dynamics

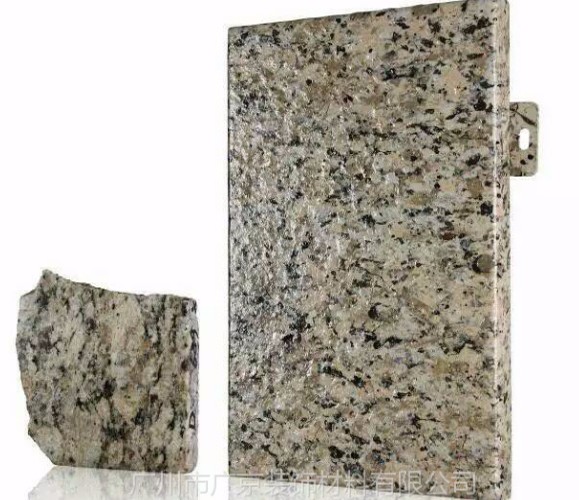

- Surface coating technology and advantages of aluminum veneer

- Aluminum veneer customization, creating personalized spatial aesthetics

- Professional team for installing fluorocarbon aluminum veneer for exterior walls

- Exploration of the relationship between outdoor ceiling aluminum veneer and environmental protection

- Honeycomb aluminum plate: the technological legend behind its lightweight design

Frequently asked questions

- What issues should be noted in the production process of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What are the characteristics of aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret power behind lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-07 18:32:42

- Click:0

Ladies and gentlemen, today let's talk about a magical material - honeycomb aluminum plate. This is not an ordinary aluminum plate, it is as lightweight as a feather, yet has unimaginable power. Are you a little curious? Then join me in unveiling the mysterious veil of honeycomb aluminum panels!

The name honeycomb aluminum plate sounds a bit fancy, but in fact it is composed of aluminum and honeycomb structure. Don't underestimate this honeycomb structure, it is the core of the honeycomb aluminum plate. The honeycomb structure is like a group of diligent little bees, connecting each small honeycomb into a solid "honeycomb network". This small mesh not only makes the honeycomb aluminum plate lightweight, but also endows it with strong load-bearing capacity and impact resistance.

Speaking of the lightness of honeycomb aluminum panels, let me give you an example. You may think that an aluminum plate is heavy, but a honeycomb aluminum plate can easily float on the water surface. This is because the honeycomb structure makes the aluminum plate very thin and evenly distributed, so its density is very low. Imagine how much our lives would change if an ordinary aluminum plate could be as lightweight as a honeycomb aluminum plate!

The powerful power of honeycomb aluminum plate is reflected in many aspects. It has good impact resistance. When you throw a honeycomb aluminum plate on the ground, it won't break into pieces like a regular aluminum plate, but will bounce back intact. This is because the honeycomb structure can disperse the impact force, allowing the aluminum plate to withstand greater pressure.

Honeycomb aluminum panels also have excellent sound insulation and thermal insulation properties. In the field of architecture, honeycomb aluminum panels are widely used in partition walls, ceilings, and other places. It can effectively isolate noise and heat, making our living environment more comfortable.

The application range of honeycomb aluminum plate is very wide. In the aerospace field, it is used to manufacture the wings and fuselage of aircraft because honeycomb aluminum panels are lightweight and strong, which can improve the aircraft's load-bearing capacity and fuel efficiency. In the field of automobile manufacturing, honeycomb aluminum panels are also used to manufacture car bodies and interiors, in order to reduce the weight of cars and improve fuel economy.

The application of honeycomb aluminum sheet is not limited to these fields. Honeycomb aluminum plates play an important role in fields such as electronic products, medical equipment, and sports equipment. Cell phone cases, laptop cases, sports equipment, etc. all rely on the presence of honeycomb aluminum panels.

How is honeycomb aluminum plate manufactured? The manufacturing process of honeycomb aluminum plate is not complicated. Cut the aluminum plate into the required size, and then use specialized equipment to imprint the honeycomb structure onto the aluminum plate. The honeycomb structure is welded together with the aluminum plate to obtain the honeycomb aluminum plate.

Although honeycomb aluminum panels have many advantages, there are also some areas that need to be noted. Honeycomb aluminum plates should not be exposed to sunlight for a long time, otherwise oxidation, discoloration and other problems may occur. Honeycomb aluminum plates also need to be careful during transportation and installation to avoid damaging the honeycomb structure.

Honeycomb aluminum plate is a magical material that is lightweight, powerful, and has a wide range of applications. With the continuous development of technology, we believe that honeycomb aluminum panels will play an important role in more fields. Hey guys, what do you think of honeycomb aluminum panels? Welcome to leave a message in the comment section for communication!

Customer service QQ

Customer service QQ