Industry information

Company News

- Aluminum curtain wall: the beauty of architecture, the soul of technology

- Honeycomb aluminum plate: a perfect combination of lightweight and aesthetics

- The Secret World of Honeycomb Aluminum Plate: The Perfect Fusion of Lightness and Strength

- Aluminum ceiling, low-key luxury in modern architecture

- The secret of aluminum honeycomb panel: the lightweight choice, the story behind it

Industry dynamics

- Exploring the development opportunities of aluminum veneer

- 2.0mm fluorocarbon aluminum veneer creates high-quality building exterior walls

- Sales channels and market promotion of aluminum veneer, strategies to enhance brand awareness

- Hyperbolic ceiling aluminum veneer creates a unique and personalized indoor space

- Design and construction technology sharing of hyperbolic curtain wall aluminum veneer

Frequently asked questions

- What are the characteristics of aluminum veneer?

- What is the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What are the main uses of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret power behind lightness

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-17 07:21:01

- Click:0

Dear readers, today let's talk about a magical material - honeycomb aluminum plate. You may find this name a bit unfamiliar, but it shines brightly in the fields of modern industry and architecture! Let me take you to explore the secrets of honeycomb aluminum panels.

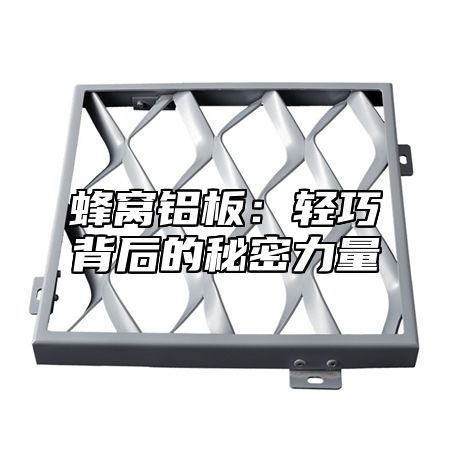

Let's talk about the origin of the name honeycomb aluminum plate. It is called a "honeycomb" because its structure is like a honeycomb, composed of countless hexagonal small units. This structure is not only aesthetically pleasing, but also has unimaginable performance. What are its secret powers?

1. Lightweight as feathers

The biggest feature of honeycomb aluminum plate is its lightness. Its density is only one-third of steel, yet its weight can be extremely light. This is due to its honeycomb structure, which greatly reduces the weight of the material while ensuring its strength. Imagine if our cars, airplanes, and high-speed trains all use honeycomb aluminum panels, how much more fuel-efficient and energy-saving it would be!

2. Amazing strength

Although honeycomb aluminum plate is lightweight, its strength should not be underestimated. Its compressive strength is 5 times that of ordinary aluminum plate, and its bending strength is 10 times that of ordinary aluminum plate. This means that honeycomb aluminum panels can withstand greater pressure while ensuring lightness. Do you think it's a bit unbelievable?

3. Good thermal insulation performance

The thermal insulation performance of honeycomb aluminum plate is also unparalleled. Its thermal conductivity is only 1/100 of that of ordinary aluminum plates, which makes it excellent in insulation and heat preservation. In the field of architecture, honeycomb aluminum panels are often used for roofs, walls, and other parts, which can reduce energy consumption and improve living comfort.

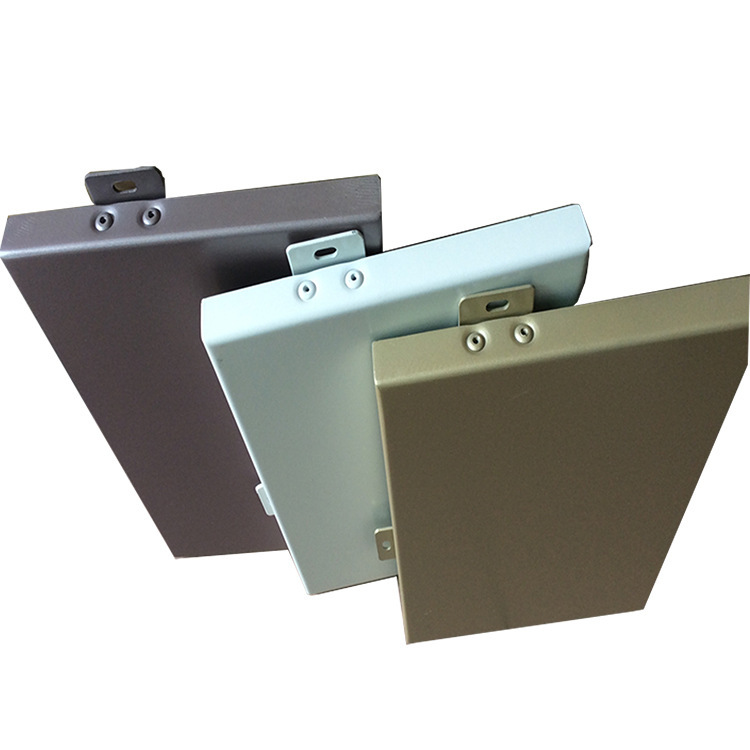

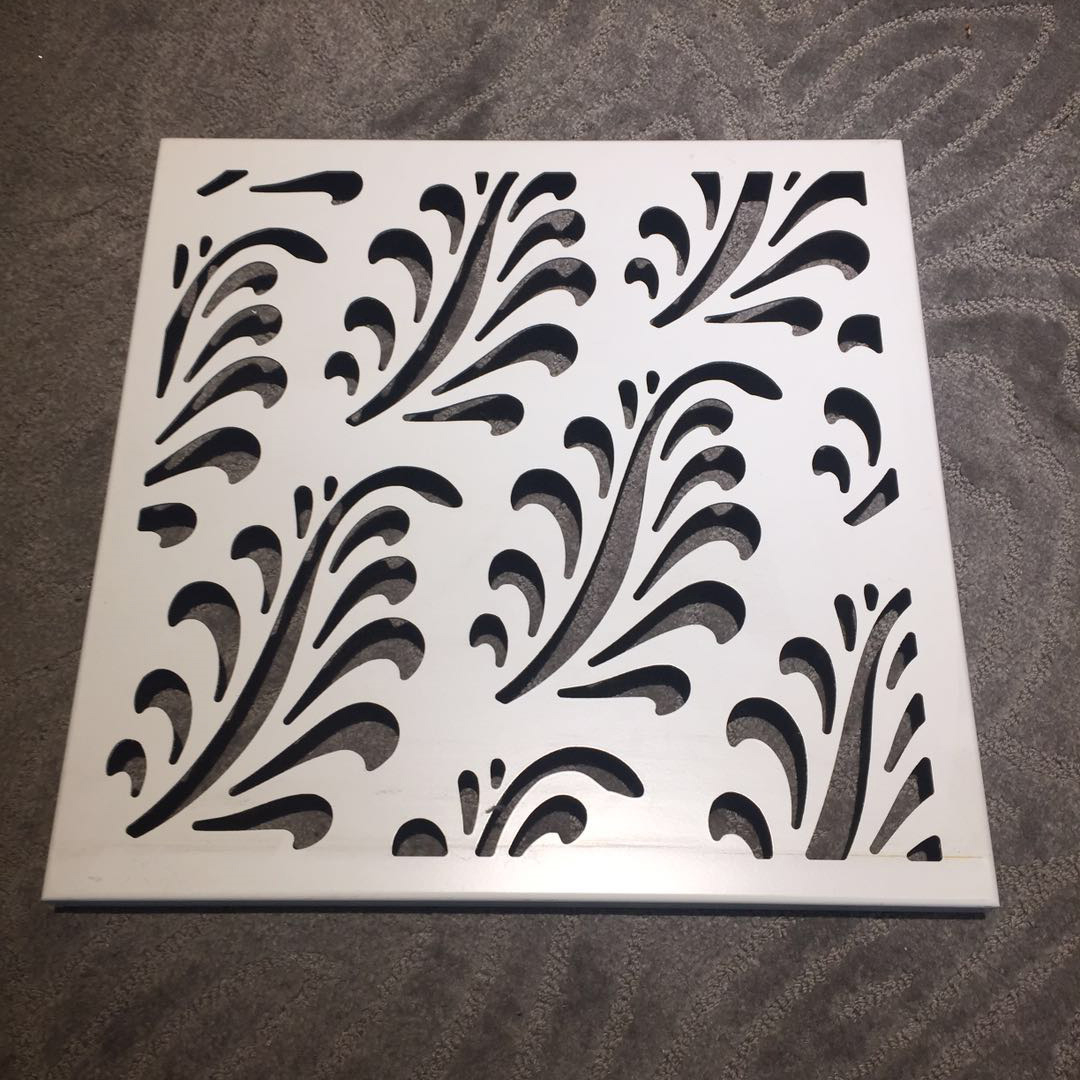

4. Beautiful and elegant

The appearance of honeycomb aluminum plate is simple and elegant, with a variety of colors that can be customized according to needs. It can be used not only in the industrial field, but also in home decoration, art production, and more. Imagine using honeycomb aluminum panels to create a stylish home space, isn't it stylish?

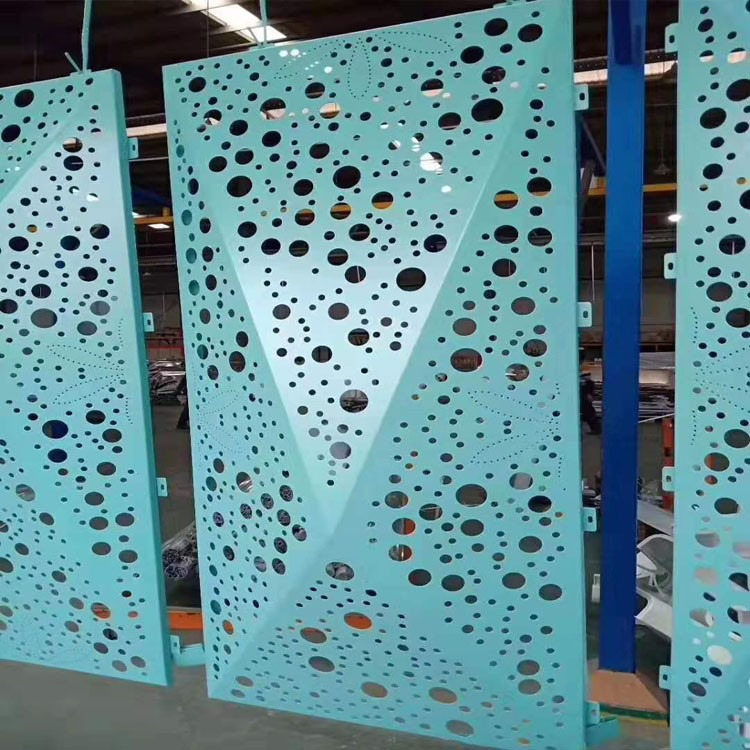

5. Widely applicable

Honeycomb aluminum plates have a wide range of applications. It can be seen in industries such as aerospace, automotive manufacturing, construction, electronics, and sports equipment. The Boeing 787 aircraft extensively uses honeycomb aluminum panels, making the aircraft lighter and more efficient.

How is honeycomb aluminum plate manufactured? Its production process is not complicated. Cut the aluminum plate into a certain size, and then use stamping, welding and other processes to make it into a honeycomb structure. Further surface treatment, such as painting, anodizing, etc., to increase its corrosion resistance.

Honeycomb aluminum plates also have their drawbacks. High cost, difficult processing, etc. But in today's constantly developing technology, these problems are gradually being solved. I believe that in the near future, honeycomb aluminum panels will unleash their magical power in more fields.

What I want to say is that honeycomb aluminum sheet, this magical material, is the crystallization of human intelligence. It shows us the secret power behind lightness and fills us with anticipation for the future. Let's look forward to honeycomb aluminum panels shining in more fields together!

Customer service QQ

Customer service QQ