Industry information

Company News

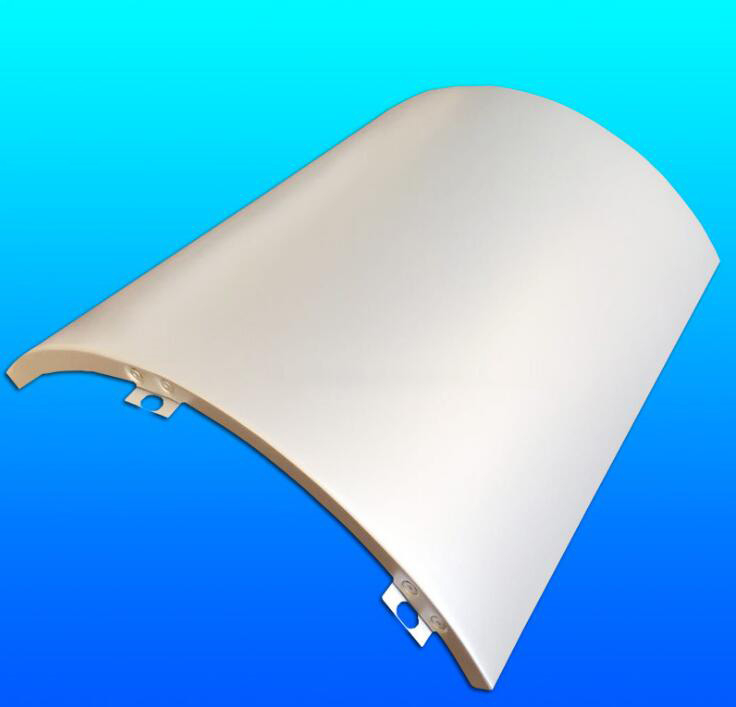

- Aluminum veneer customization, creating a new trend of personalized space

- The secret of aluminum honeycomb panel: the technological power behind its lightness

- Honeycomb aluminum plate: the secret behind its lightweight design

- Honeycomb aluminum plate: the secret behind lightness

- Aluminum ceiling, low-key luxury in modern architecture

Industry dynamics

- Carving roller coated aluminum veneer to create high-quality building exterior walls

- Aluminum Curtain Wall: The Transformation of Modern Architecture's' Outer Coat '

- Aluminum curtain wall: the fashionable coat of modern architecture

- The counterattack of aluminum honeycomb panel: lightweight and durable, the new favorite of future building materials

- Aluminum veneer curtain wall adds value to buildings

Frequently asked questions

- What are the characteristics of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

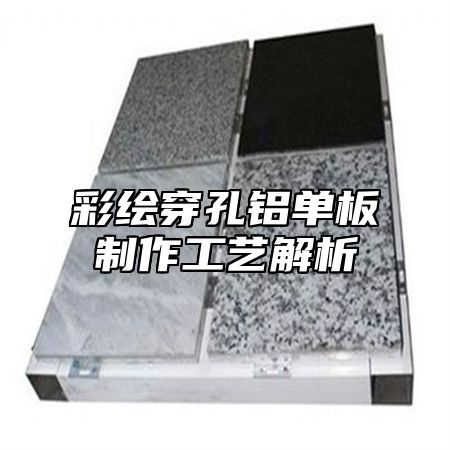

Analysis of the Production Process of Colored Perforated Aluminum Veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 04:51:12

- Click:0

Architectural decoration is an art form, not only to meet people's basic living needs, but also to create a beautiful, comfortable, and unique living and working environment. In architectural decoration, the emergence of painted perforated aluminum veneers has brought people more choices and possibilities.

1、 Production process analysis

1. Raw material preparation: The main raw materials for painted perforated aluminum veneer are aluminum alloy sheets, perforated templates, coatings, etc. Aluminum alloy sheet is the main component of painted perforated aluminum veneer, with a thickness generally between 1.0-3.5mm. Perforation templates are tools used to create holes and can be customized for production according to customer needs. Coatings are materials used to protect the surface of aluminum veneer, which can play a role in waterproofing and corrosion prevention.

2. Design and production: According to the customer's needs and design plan, first fix the perforation template on the aluminum veneer, and then use a professional punching machine for punching processing. After the punching process is completed, the design and production of colored patterns are carried out. Colorful patterns can be drawn using computer-aided design software or manually. After the drawing is completed, transfer the pattern onto the aluminum veneer and perform spraying or heat transfer printing.

3. Follow up processing: After the production of colored perforated aluminum veneer is completed, further processing is required. Including processes such as grinding, polishing, and spraying, to ensure the smoothness and color uniformity of the aluminum veneer surface. It is also necessary to carry out anti-corrosion treatment on the aluminum veneer to improve its service life and durability.

2、 Advantages of Manufacturing Process

1. High precision: The painted perforated aluminum veneer is processed by professional punching machines to ensure the accuracy of the hole size and shape of the aluminum veneer. Colorful patterns can also be accurately drawn through computer-aided design software to ensure the accuracy and completeness of the patterns.

2. Rich colors: Colored perforated aluminum veneer can be customized according to customer needs, providing a variety of colors and patterns to meet the decoration needs of different occasions. Perforation design can increase the breathability and lighting of aluminum veneer, allowing indoor air circulation and softer and more natural lighting.

3. Environmental protection and energy conservation: The painted perforated aluminum veneer is made of environmentally friendly materials, which do not contain harmful substances and comply with national environmental standards. Its surface is smooth and not easy to absorb dust, which can reduce the frequency and workload of cleaning and maintenance, thereby saving energy and costs.

3、 Practical application cases

1. Commercial Center: A certain commercial center adopts painted perforated aluminum veneer as exterior wall decoration, which has attracted the attention and focus of many consumers with its unique decorative effect and high-quality characteristics. The commercial center has also gained more business opportunities and development space due to its modern and personalized characteristics.

2. Hotel: A five-star hotel has adopted painted perforated aluminum veneer as the ceiling decoration for guest rooms, which enhances the overall quality and comfort of the rooms with its unique decorative effect and high-quality characteristics. The hotel has also attracted more consumers to stay due to its modern and luxurious atmosphere.

3. Villa: A high-end villa adopts painted perforated aluminum veneer as garden fence decoration, which enhances the overall taste and grade of the villa with its unique decorative effect and high-quality characteristics. Villas have also become a desirable living destination for many consumers due to their modern and personalized characteristics.

4、 Summary

As a new type of decorative material, painted perforated aluminum veneer brings a new visual experience to architectural decoration with its unique characteristics and advantages. By introducing its production process and analyzing practical application cases, we can better understand how to use painted perforated aluminum veneers to create personalized and creative architectural decorative effects. We believe that this product will definitely bring you unexpected surprises and satisfaction!

Customer service QQ

Customer service QQ