Industry information

Company News

- Aluminum veneer: the fashionable "light cavalry" in modern architecture

- Aluminum veneer: the fashionable new darling of modern architecture

- The secret of honeycomb aluminum plate: the perfect combination of lightness and strength

- Aluminum ceiling, poetic embellishment of modern space

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

Industry dynamics

- The unique charm of perforated painted aluminum veneer in home decoration design

- Customize aluminum veneer to make your space look brand new!

- Aluminum Curtain Landscape: Not Just the Beauty of Architecture

- Advantages and characteristics of 2.5mm painted aluminum veneer

- Sharing of construction techniques for aluminum veneer in engineering walls

Frequently asked questions

- What issues should be noted in the production process of aluminum veneer?

- What are the main uses of aluminum veneer?

- What is the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

- How long is the service life of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the characteristics of the surface treatment process for punched aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-07 20:17:28

- Click:0

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its surface treatment process is also a very important aspect. The characteristics of surface treatment technology for punched aluminum veneer will be introduced from the following aspects.

1. Definition of surface treatment process

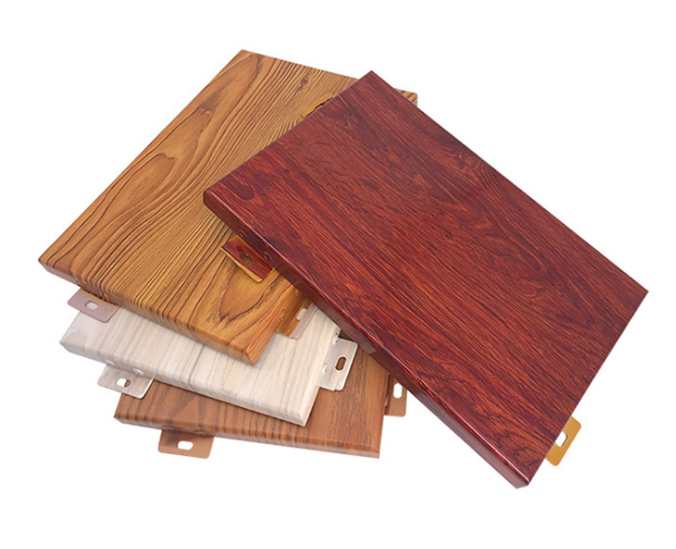

Surface treatment technology refers to the process of processing and treating the surface of punched aluminum veneer to improve its appearance quality and service life. For punched aluminum veneer, surface treatment processes include anodizing, electrophoretic coating, fluorocarbon spraying, etc.

1. Characteristics of surface treatment process

(1) Anodizing: Anodizing is a commonly used surface treatment process that can form a uniform, hard, and wear-resistant oxide film on the surface of punched aluminum veneer. This process has the characteristics of rich color, good corrosion resistance, and high hardness.

(2) Electrophoretic coating: Electrophoretic coating is an efficient and environmentally friendly surface treatment process that can achieve coating effects in multiple colors. This process has the characteristics of uniform coating, strong adhesion, and wear resistance.

(3) Fluorocarbon spraying: Fluorocarbon spraying is a high-end surface treatment process that can form a layer of fluorocarbon coating with excellent weather resistance and UV resistance on the surface of punched aluminum veneer. This process has the characteristics of bright colors, high glossiness, and good weather resistance.

1. Application scenarios of different surface treatment processes

Different surface treatment processes are suitable for different occasions and needs. For example, anodizing is suitable for indoor decorative materials with high requirements; Electrophoretic coating is suitable for outdoor billboards and streetlights that require long-term exposure to sunlight; Fluorocarbon spraying is suitable for high-end building exterior walls and large commercial centers that require good weather resistance.

1. Methods to improve surface treatment processes

In order to improve the surface treatment process quality of punched aluminum veneer, some measures can be taken. The surface treatment performance can be improved by optimizing the material composition. For example, increasing the content of alloying elements can improve the strength and hardness of aluminum alloy materials, thereby enhancing their durability. Different surface treatment methods can be used to enhance the corrosion resistance and oxidation resistance of punched aluminum veneer. A protective coating can be applied to punched aluminum veneer to reduce its contact with the external environment and extend its service life.

The surface treatment process of punched aluminum veneer is one of the important guarantees for its application effect and user experience. By optimizing material composition, surface treatment methods, and coating thickness, the surface treatment process quality of punched aluminum veneer can be improved to meet the needs of different applications.

Customer service QQ

Customer service QQ