Industry information

Company News

- The low-key luxury of aluminum ceiling industry, explore it!

- Honeycomb aluminum plate: the technological secret behind its lightweight design

- Aluminum veneer customization, creating a new proposition for personalized space

- The Secret of Aluminum Honeycomb Panels: A New Chapter of Lightweight Power in Architecture

- Aluminum veneer customization, creating exclusive space aesthetics

Industry dynamics

- Analysis of Materials and Advantages of Aluminum Single Panel for Column Suspended Ceiling

- 1.5mm roller coated aluminum veneer suitable for various architectural styles to meet individual needs

- Can aluminum veneer be used for architectural garden design?

- Innovation in Aluminum Veneer Customization Process

- Analyzing the market demand for aluminum veneer

Frequently asked questions

- How long is the service life of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the characteristics of aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to evaluate the lightning protection performance of perforated aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 9, 2025 10:52:31

- Click:0

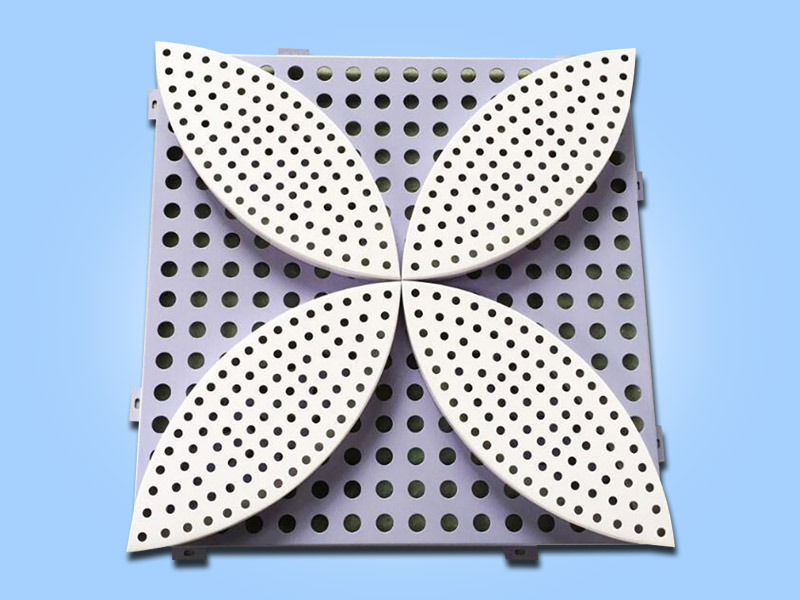

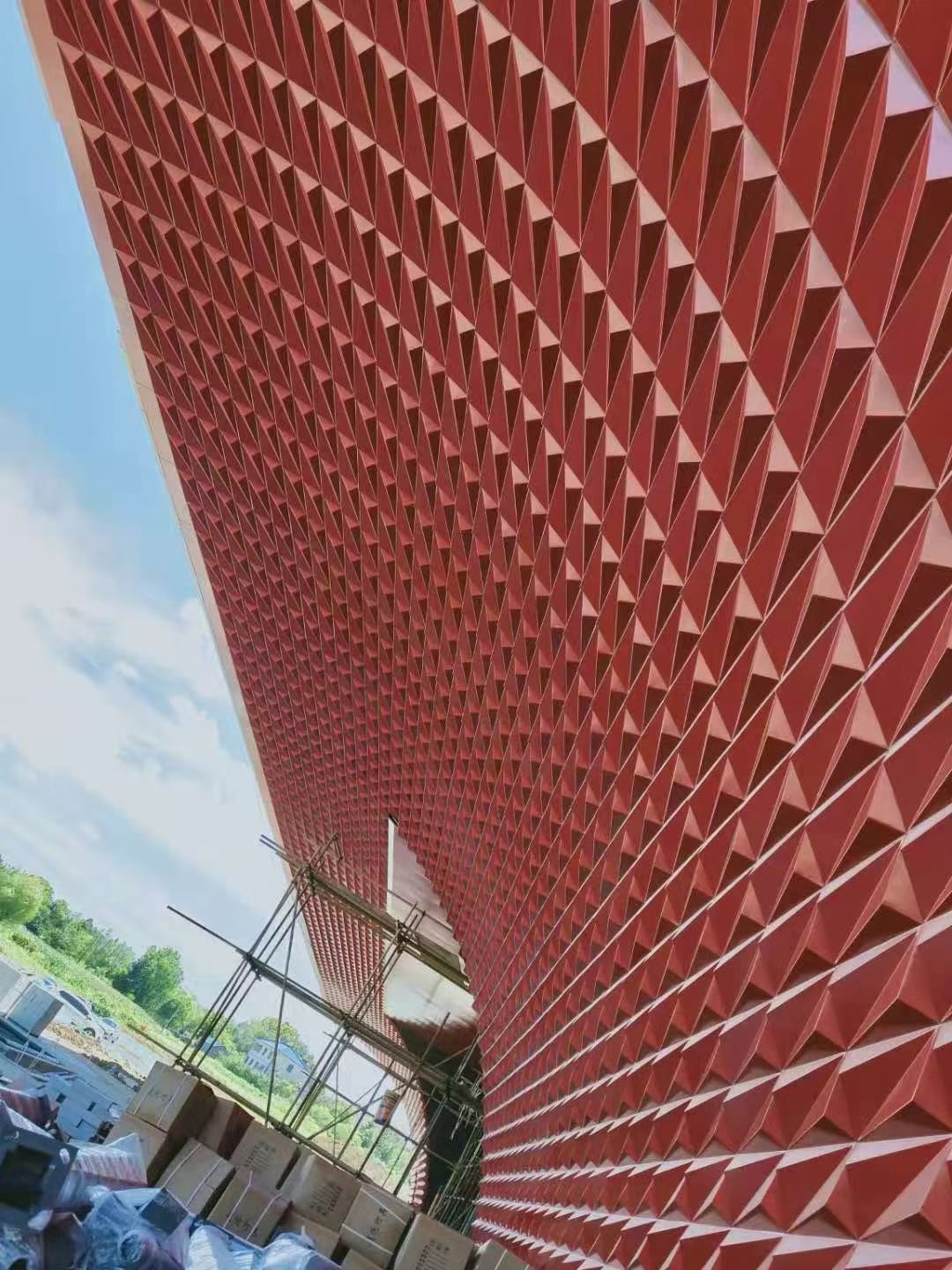

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, advertising billboards, curtain walls, etc., its lightning protection performance is also an important aspect. In order to ensure that the lightning protection performance of punched aluminum veneer meets the requirements, a series of evaluations and tests need to be conducted. The following will introduce how to evaluate the lightning protection performance of punched aluminum veneer from the following aspects.

1. Determine the evaluation criteria

Firstly, it is necessary to determine the lightning protection performance evaluation standards for punched aluminum veneer according to the actual situation. The commonly used evaluation criteria currently include national standards, industry standards, enterprise standards, etc. In practical operation, it is necessary to select appropriate evaluation criteria for assessment based on different application scenarios and requirements.

1. Conduct testing experiments

Before conducting lightning protection performance evaluation, a series of testing experiments are required. Specifically, testing can be conducted in the following ways:

(1) Conduct impact testing on punched aluminum veneer using a simulated lightning test device to observe whether there are phenomena such as breakdown and burning;

(2) Measure the grounding resistance of punched aluminum veneer using a grounding resistance tester to determine if it can effectively conduct electricity;

(3) Set other relevant testing parameters and conditions according to the actual situation.

How to improve the lightning protection performance of punched aluminum veneer?

In order to improve the lightning protection performance of punched aluminum veneer, the following measures can be taken:

(1) Select materials and coatings with good lightning protection performance;

(2) Strengthen surface treatment processes to improve their compressive, tensile, and impact resistance properties;

(3) Adopt protective measures, such as setting up lightning rods, installing lightning protection belts, etc;

(4) Regularly inspect and maintain the surface condition and structural integrity of punched aluminum veneer, and promptly address any potential problems and malfunctions.

Customer service QQ

Customer service QQ