Industry information

Company News

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- Customize aluminum veneer to create your own fashionable space

- Aluminum veneer: the beauty of architecture, the soul of details

- Aluminum ceiling, an elegant choice for modern homes

- Aluminum ceiling, a fashionable covering technique for modern spaces

Industry dynamics

- How to maintain aluminum veneer?

- Aluminum curtain wall: the "fashionable coat" of modern architecture

- How to choose a suitable price for aluminum veneer?

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What are the characteristics of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

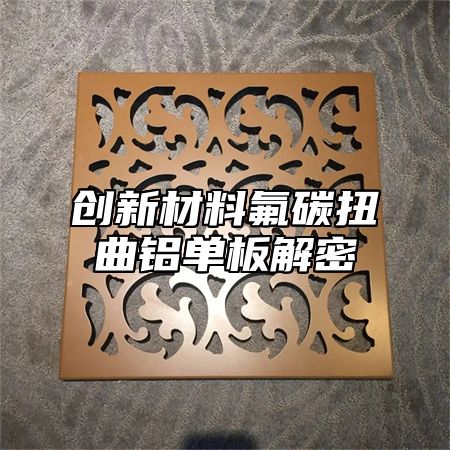

Innovative material fluorocarbon twisted aluminum veneer decryption

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 9, 2025 13:42:45

- Click:0

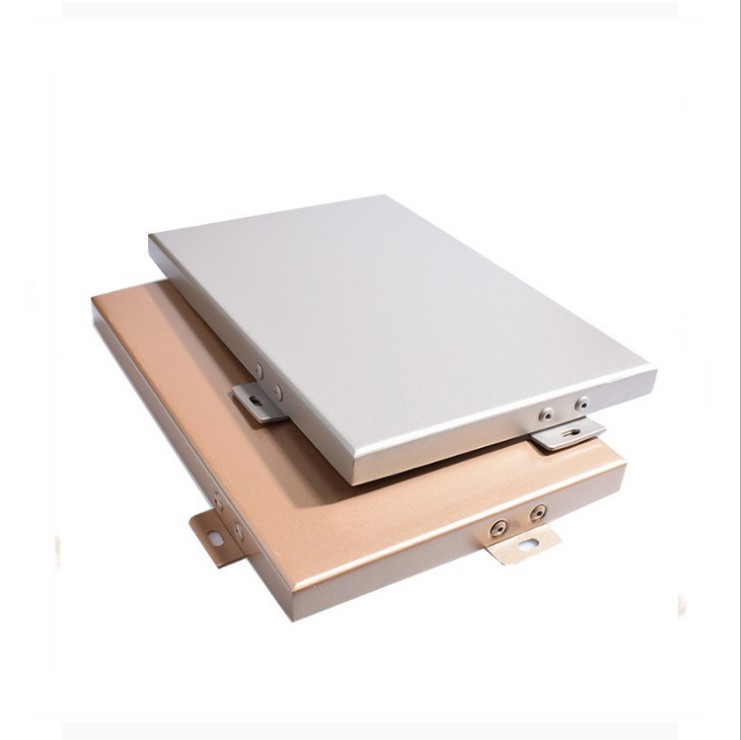

In recent years, with the continuous development and innovation of the construction industry, fluorocarbon twisted aluminum veneer has gradually entered people's vision as a new type of building material. It adopts fluorocarbon coating and twisted aluminum profiles, which have excellent corrosion resistance, fire resistance, and decorative properties, and have become one of the innovative materials that have attracted much attention in the construction industry. This article will provide an in-depth understanding of fluorocarbon twisted aluminum veneer and provide a detailed decryption of its characteristics and application scenarios.

1、 Characteristics of fluorocarbon twisted aluminum veneer

1. Excellent corrosion resistance: Fluorocarbon coatings have good corrosion resistance and can resist the erosion of harsh environments such as acid rain and salt spray, extending the service life of buildings.

2. Excellent fire resistance: Fluorocarbon twisted aluminum veneer is made of high-strength aluminum alloy material, which has excellent fire resistance after special treatment and can effectively prevent the occurrence of fires.

3. Exquisite decorative effect: The surface of fluorocarbon twisted aluminum veneer is treated with fluorocarbon spray coating, which has the characteristics of rich color, high glossiness, and diverse shapes, and can add unique beauty to buildings.

2、 Application scenarios of fluorocarbon twisted aluminum veneer

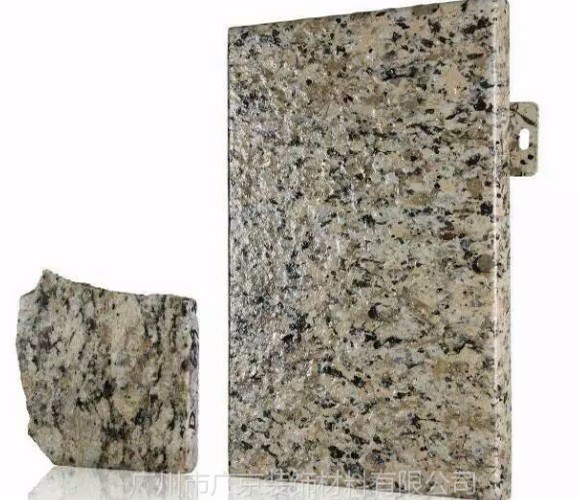

1. Commercial buildings: Fluorocarbon twisted aluminum veneer can be used for exterior wall decoration, curtain walls, doors and windows, etc., adding unique beauty and fashion to commercial buildings.

2. Residential communities: Fluorocarbon twisted aluminum veneer can be used for balcony railings, doors and windows, etc., to improve residents' quality of life and comfort.

3. Public buildings: Fluorocarbon twisted aluminum veneer can be used for exterior wall decoration, curtain walls, and other aspects to enhance the grandeur and aesthetics of public buildings.

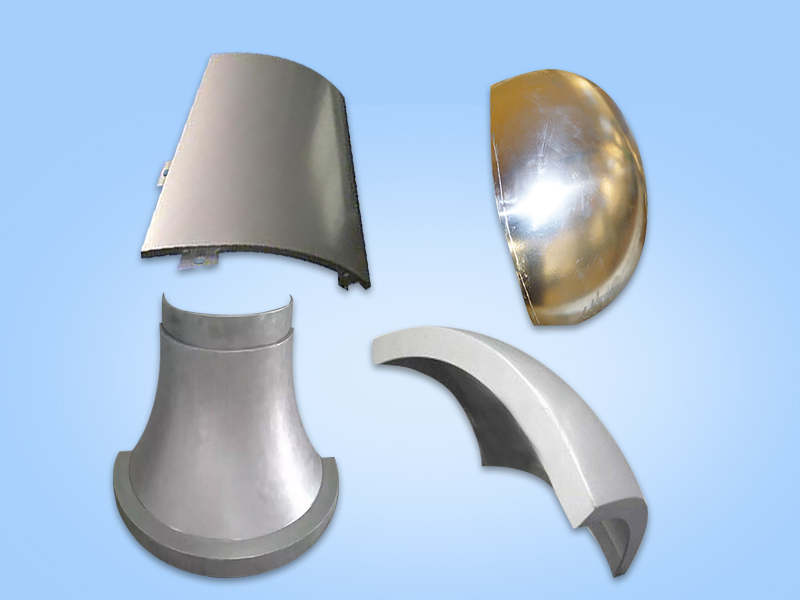

3、 The production process of fluorocarbon twisted aluminum veneer

The production process of fluorocarbon twisted aluminum veneer mainly includes the following steps:

1. Raw material preparation: High quality aluminum alloy materials are selected as the base material, and after strict screening and testing, they are ready for use.

2. Cutting and processing: Cut and process the raw materials according to the design requirements to obtain the required aluminum profiles.

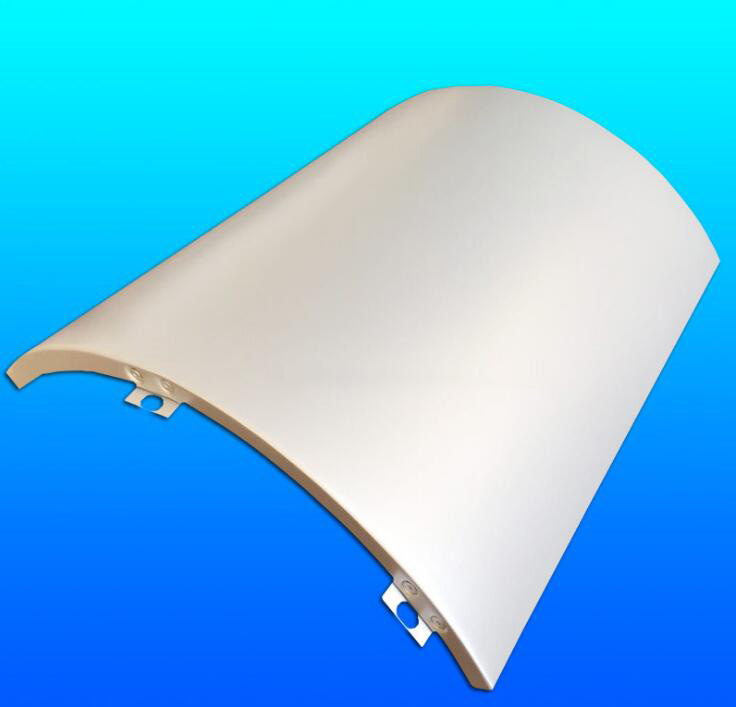

3. Bending Forming: Bending aluminum profiles to form the desired twisted shape.

4. Fluorocarbon spraying: The surface of the bent aluminum profile is treated with fluorocarbon spraying to form a uniform coating.

4、 Summary

Fluorocarbon twisted aluminum veneer, as an innovative material, has broad application prospects in the construction industry. Through reasonable application and selection, it can add unique beauty to buildings, improve insulation performance, extend service life and other advantages. In the future, with the continuous advancement of technology and the increasing demand for building materials, fluorocarbon twisted aluminum veneer will be more widely used and developed.

Customer service QQ

Customer service QQ