Industry information

Company News

- The magical world of aluminum honeycomb panels: as light as a feather, as solid as a rock

- Aluminum honeycomb panel: not just a sheet, it is a smart choice for construction!

- New trend of aluminum veneer: light luxury texture, new favorite of home furnishings

- Aluminum veneer customization, creating a new trend of personalized space!

- The charm of honeycomb aluminum plate: light as a feather, indestructible

Industry dynamics

- Green environmental characteristics and advantages of carved aluminum veneer

- What are the bending processing techniques for aluminum veneer?

- Sharing of maintenance methods for 3mm aluminum veneer in engineering

- Customized painted 2.5mm aluminum veneer to meet individual needs

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

Frequently asked questions

- What will be the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What is the market demand for aluminum veneer?

- What are the characteristics of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

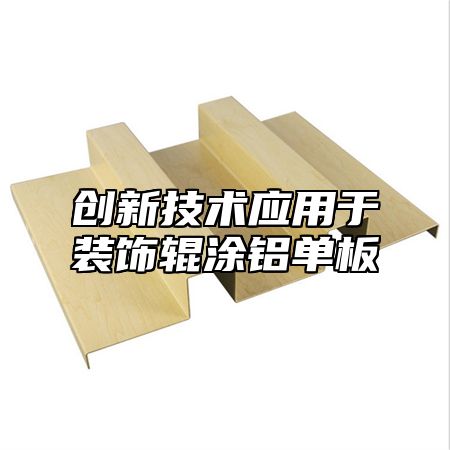

Innovative technology applied to decorative roller coated aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-10 08:27:41

- Click:0

Roller coated aluminum veneer is a high-quality decorative material with excellent weather resistance, wear resistance, and corrosion resistance. In the field of architecture and decoration, it is widely used in indoor and outdoor wall, ceiling, door and window decoration projects. With the continuous advancement of technology, innovative techniques have also been applied in the production and application of roll coated aluminum veneer, bringing more choices and possibilities for decoration engineering. This article will provide a detailed introduction to the application of innovative technology in roll coated aluminum veneer.

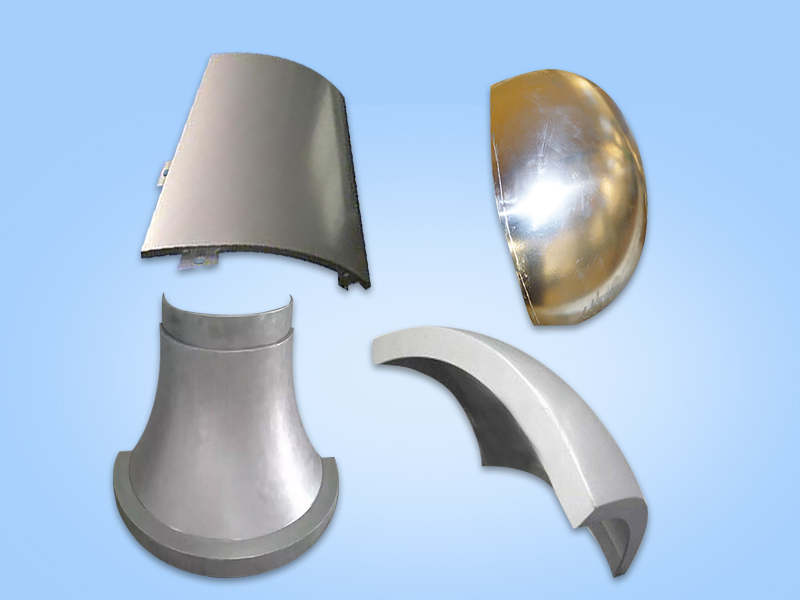

1. 3D printing technology

3D printing technology is a rapid manufacturing technique that can be used to produce components and products of various shapes and sizes. In the production of roll coated aluminum veneer, 3D printing technology can be used to create complex shapes and structures, such as arcs, circles, waves, etc. This technology can improve production efficiency and accuracy, while also meeting the personalized needs of customers.

1. Spray coating technology

Spray coating technology is a surface treatment technique that can evenly spray paint onto the surface of an object. In the production of roll coated aluminum veneers, spray coating technology can be used to produce aluminum veneers of various colors and textures. This technology can achieve large-scale production and standardized production, while also ensuring product consistency and quality stability.

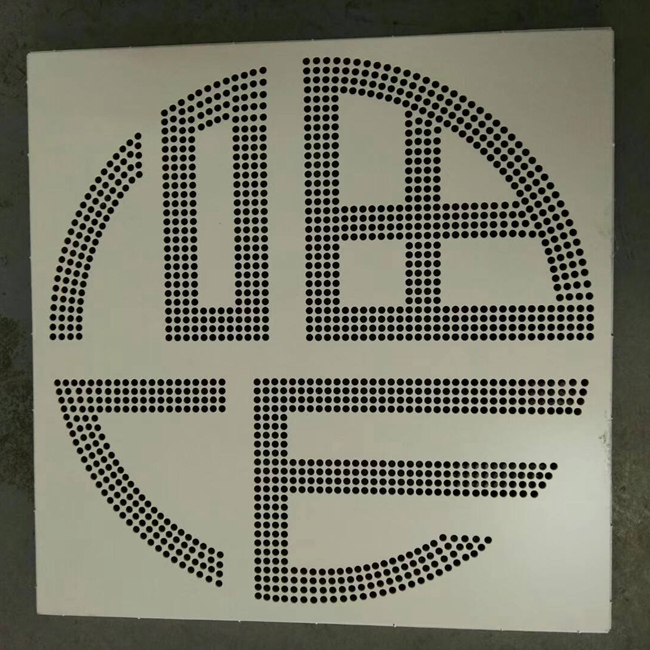

1. Laser cutting technology

Laser cutting technology is a high-precision cutting technique that can be used to cut various materials and shapes. In the production of roll coated aluminum veneers, laser cutting technology can be used to produce aluminum veneers of various shapes and sizes. This technology can improve production efficiency and accuracy, while also meeting the personalized needs of customers.

The application of innovative technology has brought more choices and possibilities for the production and application of roll coated aluminum veneer. In the future, with the continuous progress and development of technology, it is believed that more innovative technologies will be applied to the production and application of roll coated aluminum veneer.

Customer service QQ

Customer service QQ