Industry information

Company News

- Aluminum veneer: the fashionable new darling of modern architecture

- Aluminum ceiling: the new darling of modern home decoration

- The physical and mechanical properties of aluminum veneer and its applications in different fields

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Aluminum curtain wall: the fashionable choice in modern architecture?

Industry dynamics

- Analysis of the service life of 3mm aluminum veneer

- Aluminum veneer customization quality and safety assurance

- Aluminum veneer improves the environmental and sustainable performance of buildings

- Aluminum veneer customization, creating a new trend of personalized space

- Sales channels and market promotion of aluminum veneer, as well as strategies to enhance brand awareness

Frequently asked questions

- What is the market demand for aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What issues should be noted in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Characteristics and advantages analysis of perforated aluminum veneer in construction

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 00:08:44

- Click:0

Architectural punched aluminum veneer is a new type of building decoration material that has been widely used in the construction industry due to its unique appearance and excellent performance. This article will provide a detailed analysis of the characteristics and advantages of perforated aluminum veneer in architecture.

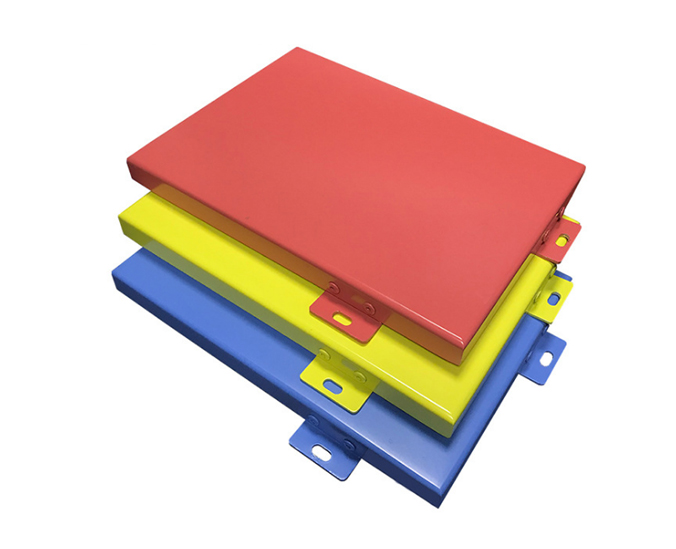

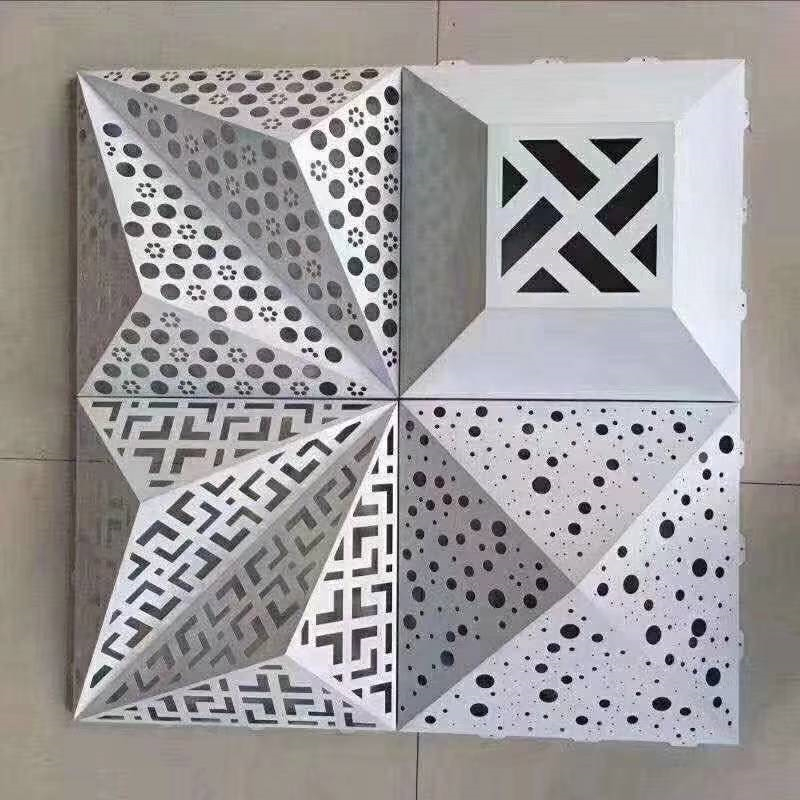

Architectural perforated aluminum veneer has good decorative properties. Its surface can be customized in various shapes and sizes according to the designer's design requirements, such as circular, square, long strip, etc. Architectural punched aluminum veneer can also be sprayed in various colors to coordinate with the surrounding environment, further enhancing the aesthetics of the building.

Architectural perforated aluminum veneer has excellent weather resistance and corrosion resistance. This enables it to maintain stable performance in various harsh environments, such as acid rain, salt spray, etc. Whether in parks, squares, or on both sides of streets, perforated aluminum panels in buildings can effectively cope with changes in various climatic conditions and maintain their beautiful appearance.

Architectural perforated aluminum veneer has good plasticity. It can be customized in various shapes and sizes according to the design needs of designers to meet different architectural decoration requirements. The lightweight of perforated aluminum veneer in construction can greatly reduce the manpower and material resources required during the construction process.

Architectural perforated aluminum veneer also has good sound insulation and thermal insulation performance. This has made it widely used in situations where it is necessary to improve the comfort level inside buildings, such as office buildings, hotels, etc. These characteristics also make perforated aluminum veneer in buildings have great potential in energy conservation and environmental protection.

Architectural perforated aluminum veneer has high installation efficiency. Compared to traditional building materials such as stone and glass, the installation process of perforated aluminum veneer in buildings is simpler and faster. Due to its lightweight, it can greatly reduce the manpower and material resources required during the construction process.

Architectural perforated aluminum veneer provides a new option for the construction industry with its unique performance and beautiful appearance. Through reasonable design and application, we can fully leverage its advantages and improve the overall quality and aesthetics of buildings. Although perforated aluminum veneer has broad application prospects in the construction industry, there are still some issues that need to be addressed. For example, how to ensure the quality and accuracy of punching, how to handle the relationship between punching and color, etc. These issues require us to constantly explore and research in practical applications.

Customer service QQ

Customer service QQ