Industry information

Company News

- Honeycomb aluminum plate: a perfect fusion of lightness and sturdiness

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- The secret of aluminum honeycomb panel: the perfect combination of lightness and sturdiness

- The Fantasy Journey of Honeycomb Aluminum Plate: The Mystery Behind Lightness

Industry dynamics

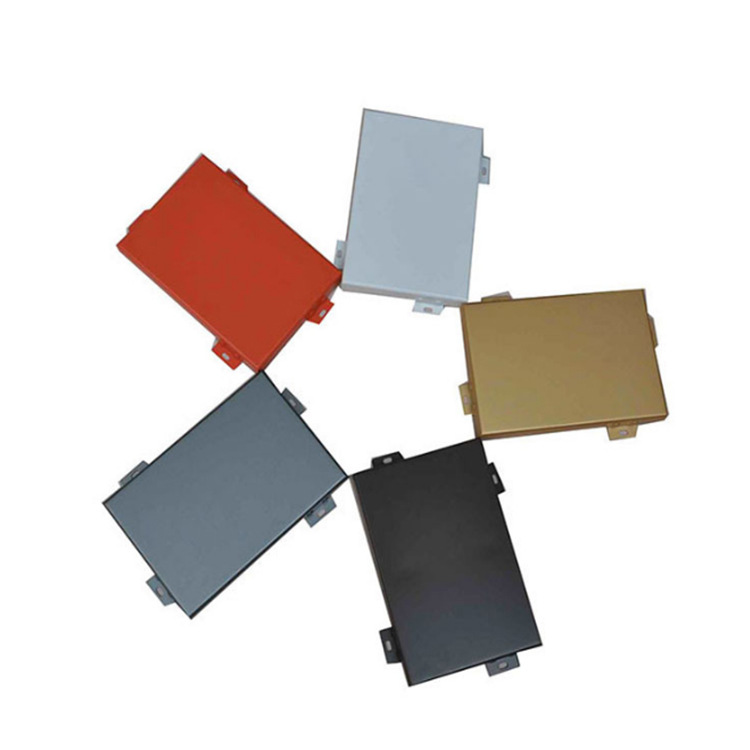

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer is a perfect combination of affordable price, quality, and design

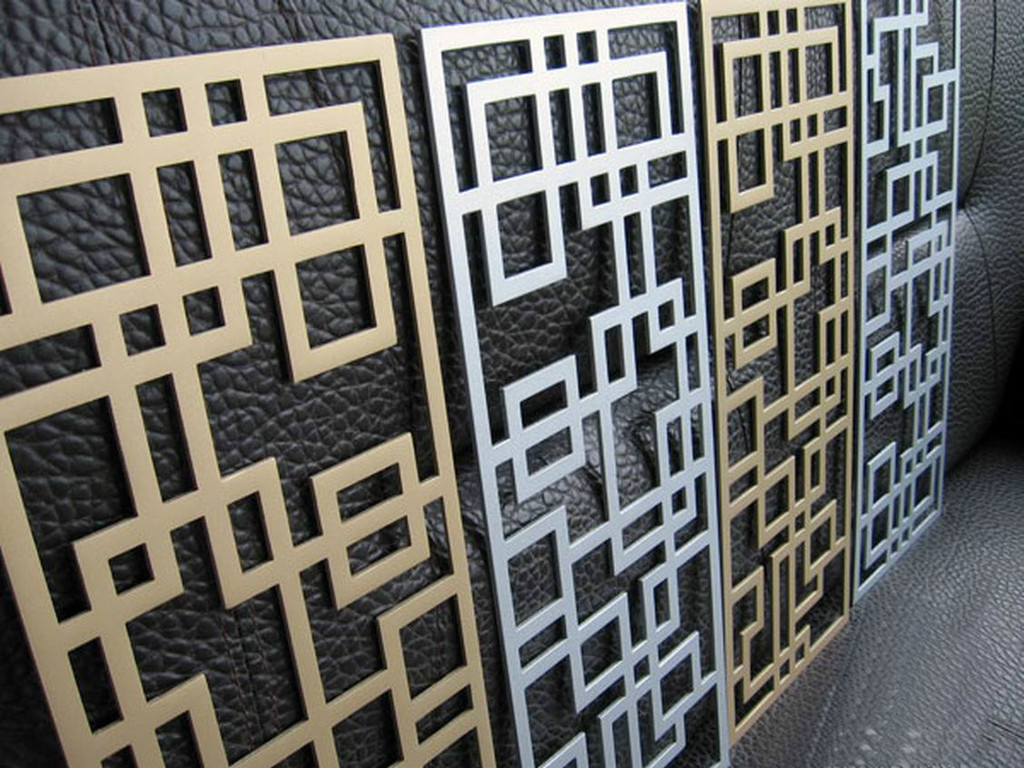

- What is the difference between punched aluminum veneer and carved aluminum veneer?

- Aluminum veneer: the fashionable "coat" of modern architecture

- Customize aluminum veneer to make the space more stylish

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- What is the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the main uses of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

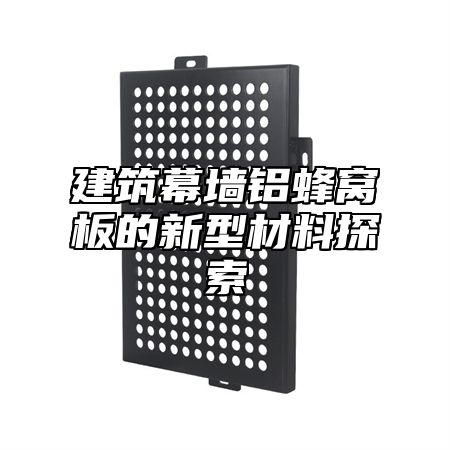

Exploration of New Materials for Aluminum Honeycomb Panels in Building Curtain Walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 14:50:25

- Click:0

With the continuous advancement of technology, building materials are also constantly being updated and replaced. In recent years, aluminum honeycomb panels for building curtain walls have attracted much attention as a new type of material. It has the advantages of lightweight, high strength, corrosion resistance, sound insulation, fire prevention, etc., and is widely used in fields such as building curtain walls, roofs, and walls.

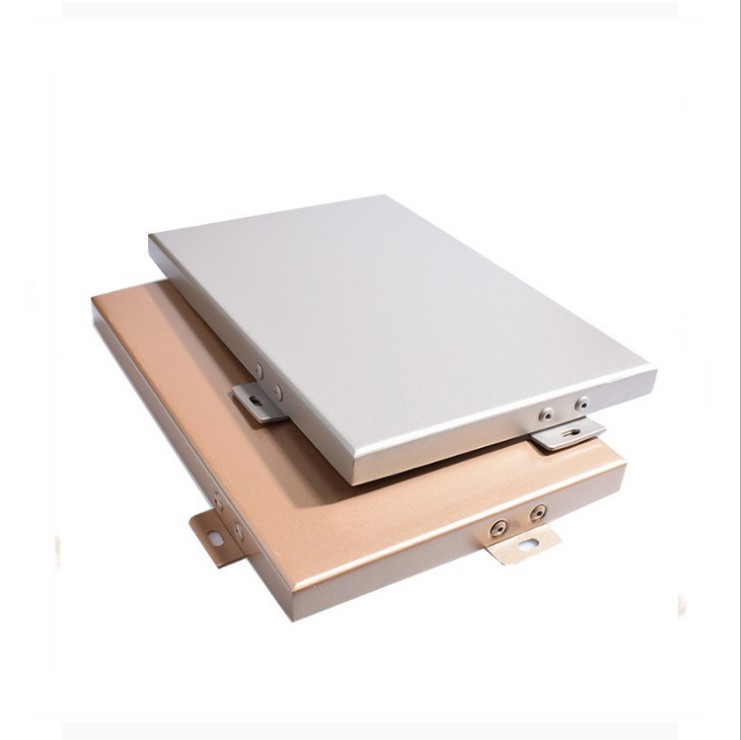

Aluminum honeycomb panels for building curtain walls have the characteristic of being lightweight. Compared to traditional building materials such as concrete and steel, aluminum honeycomb panels are lighter in weight and can effectively reduce the weight of buildings and lower their overall cost. Due to its high strength, it is also more convenient and efficient during the construction process.

Aluminum honeycomb panels for building curtain walls have the characteristic of high strength. Aluminum honeycomb panel is made of aluminum alloy material, and after special processing technology, it can form a honeycomb structure to improve its strength and stability. This enables it to withstand greater natural forces such as wind pressure and snow pressure, ensuring the safety and stability of the building.

Aluminum honeycomb panels for building curtain walls also have good corrosion resistance. After special treatment on the surface of aluminum honeycomb panels, a dense oxide film can be formed to prevent the metal from coming into contact with oxygen in the air, thus avoiding corrosion. Even in harsh environments such as seawater, acid rain, etc., aluminum honeycomb panels can maintain good performance.

In addition, aluminum honeycomb panels for building curtain walls also have good sound insulation effects. The aluminum honeycomb panel is composed of a porous structure inside, which can effectively isolate the propagation of noise and achieve the effect of noise reduction. This is very important for places that require a quiet environment, such as hospitals, schools, etc.

Aluminum honeycomb panels for building curtain walls also have the characteristic of good fire resistance. After special treatment, a dense oxide film can be formed on the surface of aluminum honeycomb panels to prevent corrosion from fire sources. Due to its low density, it is not easy to cause large-scale combustion in the event of a fire.

Aluminum honeycomb panels for building curtain walls, as a new type of material, have advantages such as lightweight, high strength, corrosion resistance, sound insulation, and fire resistance. In the future, with the development of technology and the increasing awareness of environmental protection among people, it is believed that its application scope will become more and more extensive.

Customer service QQ

Customer service QQ