Industry information

Company News

- Aluminum veneer, the fashionable choice in architecture!

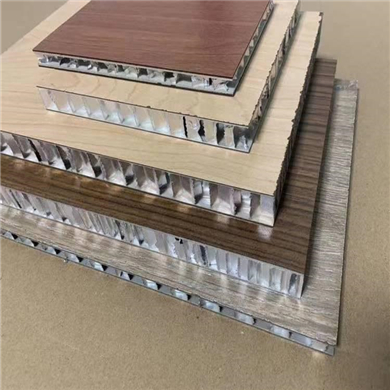

- The magical world of honeycomb aluminum plate: the perfect combination of lightness and strength

- Aluminum ceiling, the 'invisible artwork' of modern space

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer customization, creating exclusive space aesthetics

Industry dynamics

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum Curtain Wall: The Charm Coat of Modern Architecture

- Installation method and precautions for 2.0mm aluminum veneer ceiling

- Aluminum veneer improves the environmental and sustainable performance of buildings

- The wonderful world of honeycomb aluminum plate: the perfect combination of lightness and strength

Frequently asked questions

- What are the characteristics of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What are the main uses of aluminum veneer?

- What is the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and characteristics of hollow aluminum veneer for exterior walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 27, 2025 02:56:11

- Click:0

Hollow aluminum veneer for exterior walls is a new type of building material that has the advantages of lightweight, high strength, beautiful appearance, environmental protection, and energy saving. Its production process and characteristics are also very unique. Below, we will introduce in detail the production process and characteristics of hollow exterior aluminum veneer.

1、 Production process

1. Raw material preparation

The main raw material for hollow exterior wall aluminum veneer is aluminum alloy material. Before production, strict inspection and screening of raw materials are required to ensure that they meet quality requirements. Other auxiliary materials such as sealant and screws also need to be prepared.

1. Cutting and processing

Cutting and processing aluminum alloy materials according to the design dimensions is the first step in making hollow exterior wall aluminum veneers. Cutting and processing require the use of professional equipment and technology to ensure cutting accuracy and surface quality.

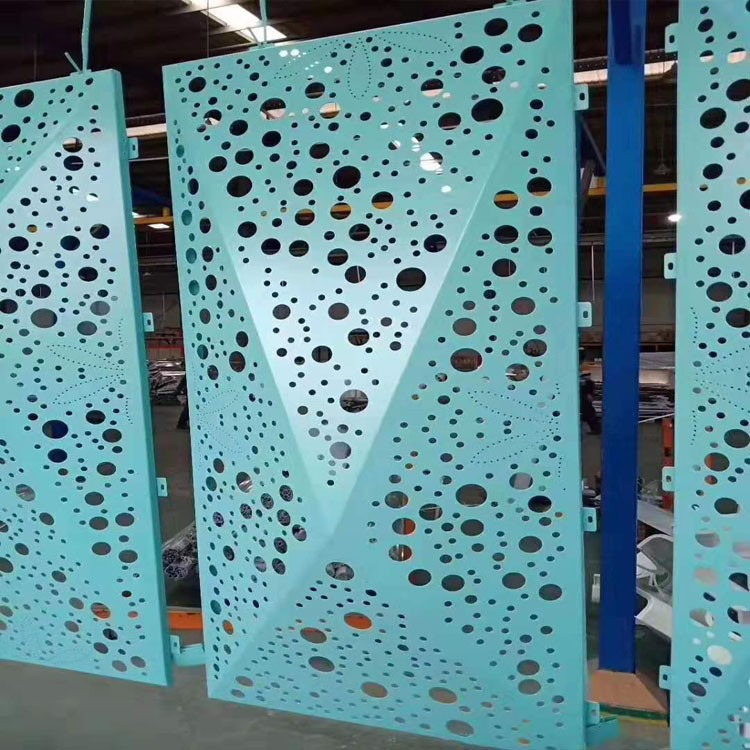

1. Drilling processing

Drilling holes on the cut aluminum alloy sheet is one of the key steps in making hollow aluminum veneer for exterior walls. Drilling processing requires the use of equipment such as drilling machines or punching machines to accurately determine the position and size of holes according to design requirements.

1. Welding processing

Welding the perforated aluminum alloy sheet is one of the important steps in making hollow exterior wall aluminum veneer. Welding processing requires the use of professional welding equipment and techniques to ensure welding strength and sealing.

2、 Characteristic Introduction

1. Lightweight and high-strength

Hollow aluminum veneer for exterior walls has higher weight and strength compared to traditional building materials, making it more flexible and convenient in the design and construction of buildings.

1. Beautiful and elegant

The hollow exterior aluminum veneer is processed using hollow technology, which can create various patterns and textures, making the building more beautiful and unique. It can also be combined with other building materials such as glass curtain walls and stone curtain walls to form a more diverse and colorful architectural style.

1. Thermal insulation

Hollow aluminum veneer for exterior walls has lower energy consumption compared to traditional building materials because it can effectively insulate and reduce the energy consumption of buildings. Hollow out exterior aluminum veneer also has good sound insulation effect, which can reduce noise pollution.

1. Recyclability

The hollow exterior wall aluminum veneer is made of aluminum alloy material, which can be recycled and greatly reduces its impact on the environment. Compared with traditional building materials, hollow aluminum veneer for exterior walls has a higher recycling rate.

Hollow aluminum veneer for exterior walls has the characteristics of lightweight, high strength, beautiful appearance, thermal insulation, and recyclability. In the future construction industry, with the increasing awareness of environmental protection and continuous technological progress, it is believed that it will be widely applied and developed.

Customer service QQ

Customer service QQ