Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum ceiling: a fashionable choice for creating modern spaces

- Aluminum ceiling: low-key luxury in modern architecture

- The wonderful world of honeycomb aluminum plate: the perfect fusion of lightness and strength

- Aluminum Ceiling: The 'Sky Garden' of Modern Architecture

Industry dynamics

- The magical charm of aluminum honeycomb panel: lightweight and high-strength, the new favorite of future building materials

- Aluminum honeycomb panel: the invisible 'magician' in the construction industry

- Aluminum veneer: the new darling of the construction industry, the perfect combination of environmental protection and aesthetics

- The wide application of durable and practical aluminum veneer in architectural decoration

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- How long is the service life of aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Common surface fluorocarbon spraying technology for aluminum veneer treatment

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 06:16:29

- Click:0

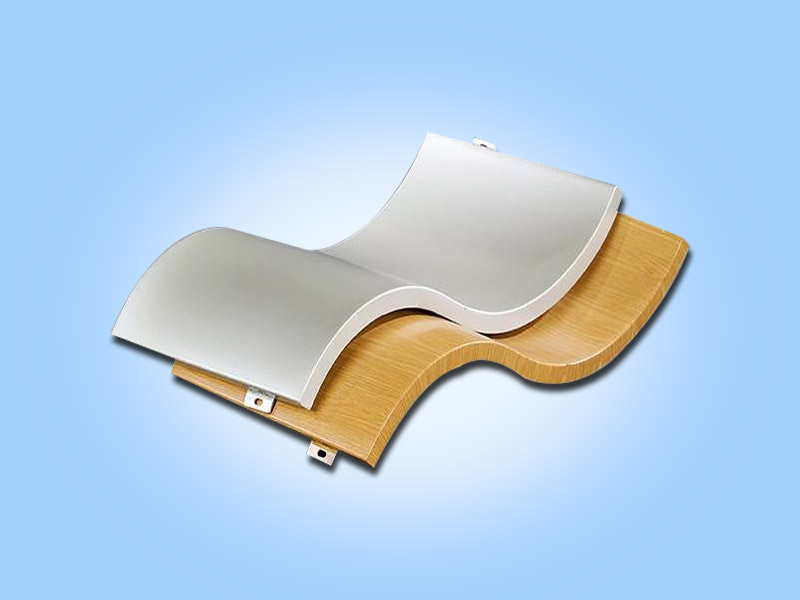

In modern architectural decoration, aluminum veneer is increasingly favored by people due to its unique performance and beautiful appearance. The surface treatment technology of aluminum veneer, especially fluorocarbon spraying technology, gives it better weather resistance, wear resistance, and color durability. What is fluorocarbon spraying technology? This article will provide a detailed introduction to the fluorocarbon spraying technology for aluminum veneer treatment.

Let's learn about fluorocarbon spraying technology. Fluorocarbon spraying is a technology that uses fluorocarbon coatings for surface treatment. Fluorocarbon coatings have good weather resistance, wear resistance, and color persistence, which can effectively improve the service life and decorative effect of aluminum veneers. Fluorocarbon coating is composed of fluororesin, carbon atoms, and other additives, which are treated with special processes to form a uniform and dense protective film.

Next, let's explore the advantages of fluorocarbon spraying on aluminum veneer. The main advantages of fluorocarbon spraying on aluminum veneer are as follows:

1. Strong weather resistance: Fluorocarbon coatings have good weather resistance, which means that their color and performance will not undergo significant changes under the influence of natural environments such as sunlight, rain, wind and snow. This enables aluminum veneer to maintain long-lasting aesthetics and stability in outdoor environments.

2. Good wear resistance: Fluorocarbon coatings have excellent wear resistance and can maintain a good surface condition even in environments with frequent friction and scratching. This is particularly important for places that require regular cleaning and maintenance, such as public places and high-rise buildings.

3. Long lasting color: Fluorocarbon coatings have a wide range of colors and excellent color persistence, even after years of use, there will be no significant fading phenomenon. This enables aluminum veneer to maintain a good decorative effect throughout long-term use.

Let's learn about the treatment process of fluorocarbon spraying on aluminum veneer. The fluorocarbon spraying of aluminum veneer mainly involves the following steps:

1. Surface pretreatment: Firstly, the surface of the aluminum veneer needs to be pretreated, including cleaning, polishing, removing oil stains, etc., to ensure that the fluorocarbon coating can firmly adhere to the aluminum veneer.

2. Painting: After completing the pre-treatment, painting can begin. Painting is usually divided into two stages: primer and topcoat. Primer mainly enhances adhesion and improves corrosion resistance, while topcoat mainly serves as decoration and protection.

3. Baking: After the coating is completed, the aluminum veneer needs to be baked to allow the fluorocarbon coating to fully cure and form a uniform protective film. The baking temperature and time need to be determined based on the specific fluorocarbon coating and aluminum veneer.

Let's explore the application areas of fluorocarbon spraying on aluminum veneer. Due to its excellent weather resistance, wear resistance, and color durability, fluorocarbon coating on aluminum veneer is widely used in the following fields:

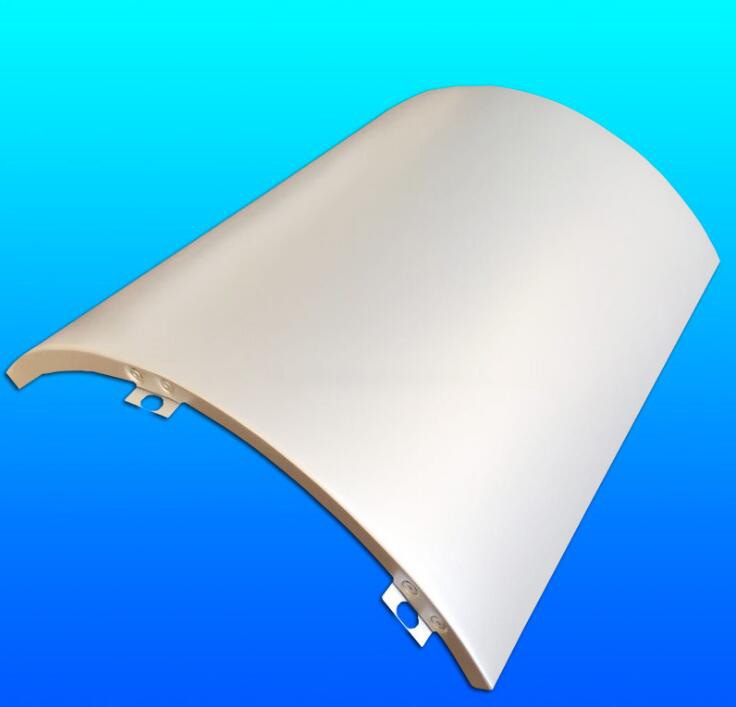

1. Building curtain wall: Aluminum veneer, as the main material of building curtain walls, can effectively resist the erosion of natural factors such as wind pressure and rain, while also having good thermal insulation and thermal insulation properties.

2. Indoor Ceiling: Aluminum veneer can be used for the decoration of indoor ceilings, which can not only block pipes but also increase the aesthetic appeal of indoor spaces. Aluminum veneer can also be combined with other decorative materials to create unique indoor decorative effects.

3. Partition wall: Aluminum veneer can be used for the decoration of partition walls. With its lightweight and high-strength characteristics, it can effectively reduce the burden on the wall and improve its sound insulation and thermal insulation performance.

Customer service QQ

Customer service QQ