Industry information

Company News

- Aluminum ceiling, the new darling of fashionable home decor!

- Aluminum veneer is not just about wall decoration!

- Customized aluminum veneer to create your own unique aesthetic space

- Aluminum curtain wall, revealing the 'invisible armor' in architecture!

- Aluminum veneer customization, creating a new choice for personalized space!

Industry dynamics

- Wear resistance of imitation wood grain aluminum veneer

- Aluminum curtain wall: the new aesthetic favorite of modern architecture

- The secret of aluminum honeycomb panel: the perfect fusion of lightness and sturdiness

- Aluminum curtain wall, the fashionable new darling of the construction industry!

- Rust prevention performance and long-term protection of aluminum veneer

Frequently asked questions

- What is the future development trend of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

- How to increase the market demand for aluminum veneer?

- What is the market demand for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer manufacturer's product quality inspection process

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 23:58:54

- Click:0

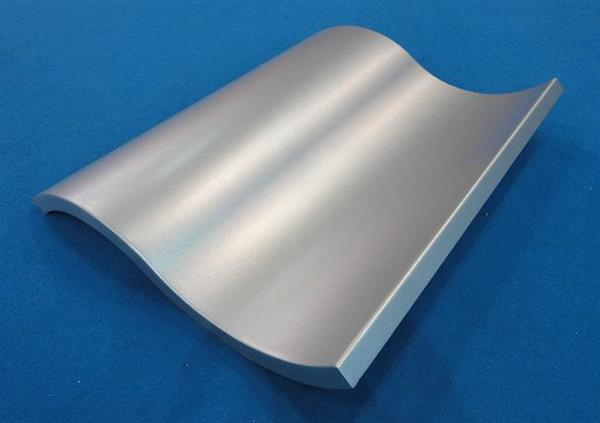

Aluminum veneer, as a building decoration material, its product quality inspection is one of the important guarantees for customers to choose. Below is a detailed introduction to the product quality inspection process of aluminum veneer manufacturers.

1、 Raw material quality inspection

1. Chemical composition testing: The main raw material of aluminum veneer is aluminum, and the chemical composition of aluminum should be tested to ensure that the product meets national standard requirements.

2. Physical performance testing: The physical properties of aluminum veneer are also important quality indicators, and the hardness, density, tensile strength, etc. of the product should be tested.

3. Surface treatment quality inspection: There are various surface treatment methods for aluminum veneer, such as spraying, anodizing, powder coating, etc. The quality of surface treatment should be inspected to ensure that the product quality meets the standard requirements.

2、 Production process quality inspection

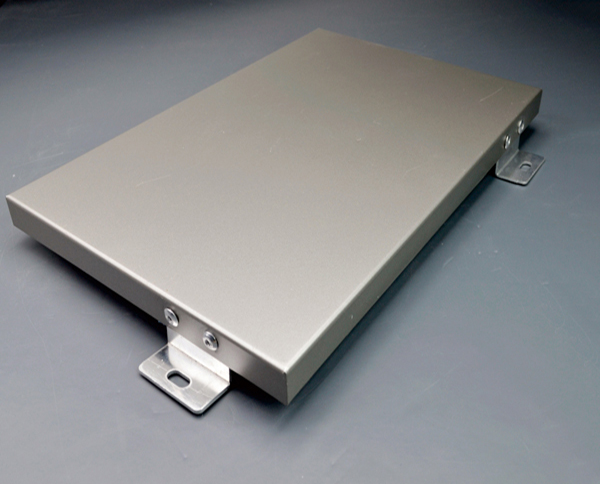

1. Thickness and length accuracy testing: The thickness and length accuracy of aluminum veneer are also important quality indicators, and the thickness and length of the product should be accurately measured and tested.

2. Flatness and angle accuracy testing: The flatness and angle of aluminum veneer are also important quality indicators, and the flatness and angle of the product should be accurately measured and tested.

3. Coating thickness detection: The coating thickness of aluminum veneer is also an important quality indicator, and the coating thickness of the product should be accurately measured and detected.

3、 Finished product quality inspection

1. Appearance quality inspection: The appearance quality of aluminum veneer is also an important quality indicator, and the surface flatness, color uniformity, defects, and other issues of the product should be inspected and evaluated.

2. Strength and stability testing: The strength and stability of aluminum veneer are also important quality indicators, and the strength and stability of the product should be tested and evaluated.

3. Safety testing: The use environment of aluminum veneer also has certain safety requirements, and the fire resistance and corrosion resistance of the product should be tested and evaluated.

4、 After sales service quality inspection

1. Installation effect testing: The installation effect of aluminum veneer is also an important quality indicator, and the installation effect of the product should be inspected and evaluated.

2. Maintenance effect testing: The maintenance effect of aluminum veneer is also an important quality indicator, and the maintenance effect of the product should be inspected and evaluated.

3. Complaint handling effectiveness testing: If there are customer complaints or feedback, their handling effectiveness should be checked and evaluated.

The product quality inspection process of aluminum veneer manufacturers mainly includes raw material quality inspection, production process quality inspection, finished product quality inspection, and after-sales service quality inspection. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ