Industry information

Company News

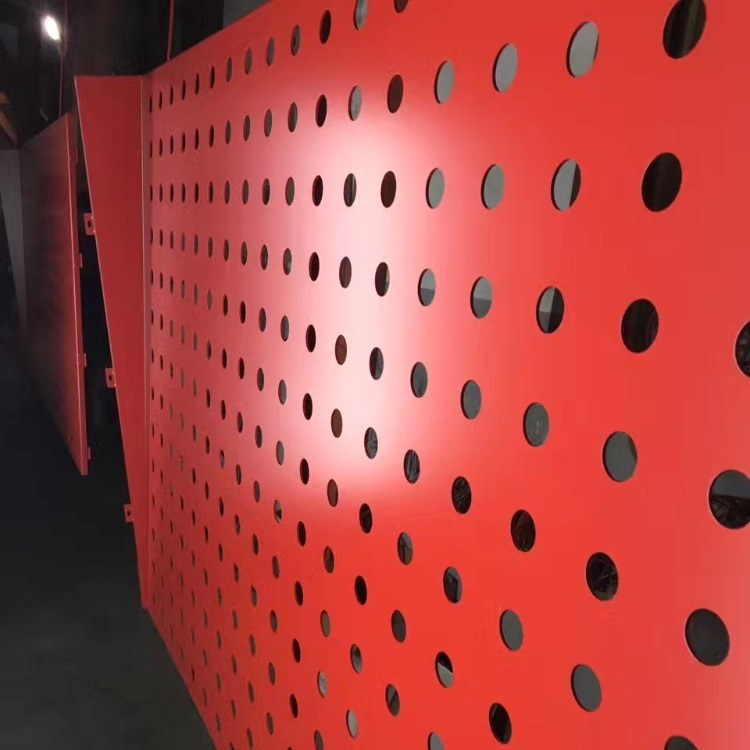

- Aluminum veneer customization, creating a new trend of personalized space!

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock

- Aluminum Curtain Feast: A New Chapter in Modern Architectural Aesthetics

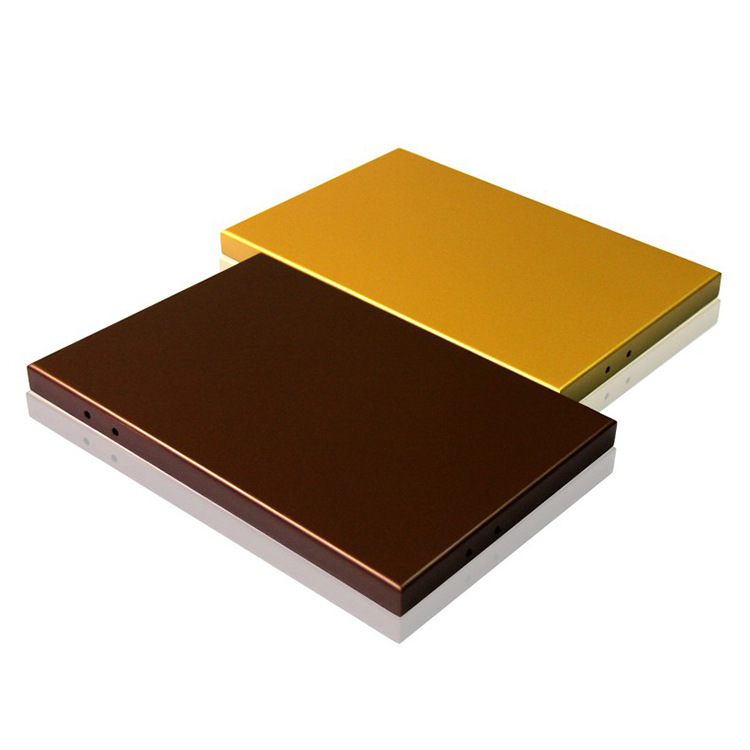

- Key technologies required for the production and processing of aluminum veneer

- The magical world of honeycomb aluminum plate: the perfect combination of lightness and strength

Industry dynamics

- Interior design with aluminum veneer decoration

- Aluminum veneer customization makes your store more attractive

- Aluminum curtain wall: the fashionable coat of modern architecture

- The production process and technical characteristics of aluminum veneer

- Aluminum veneer: the fashionable outerwear of modern architecture

Frequently asked questions

- What environmental issues should be paid attention to in the production process of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- How long is the service life of aluminum veneer?

- What is the market demand for aluminum veneer?

- What are the main uses of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the installation environment requirements for aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 11:13:10

- Click:0

Aluminum veneer is a widely used building material in fields such as architecture, billboards, curtain walls, etc., and its installation environment requirements are also very important. The following will provide a detailed introduction to the installation environment requirements and precautions for aluminum veneer.

1. Temperature requirements

Before installing aluminum veneer, it is necessary to consider the ambient temperature in which it is located to ensure its normal use. Generally speaking, the temperature range for the use of aluminum veneer is between -10 ° C and 45 ° C. Exceeding this range may cause deformation or damage to the aluminum veneer. Before installation, it is necessary to check and evaluate the ambient temperature.

1. Humidity requirements

Humidity is also one of the important factors affecting the installation of aluminum veneer. Aluminum veneer is easily affected by moisture during use, leading to rusting or corrosion. When installing aluminum veneer, attention should be paid to the humidity of the environment, and installation should be avoided as much as possible in humid environments.

1. Lighting requirements

Aluminum veneer also requires appropriate lighting to achieve its optimal performance. If the aluminum veneer is in a dark environment, it may cause uneven color or other problems. When installing, it is necessary to consider the ambient lighting conditions of the aluminum veneer and place it in a well lit location as much as possible.

1. Wind requirements

Aluminum veneer is easily affected by wind during use, leading to deformation or damage. When installing, it is necessary to consider the wind conditions in the environment where the aluminum veneer is located, and try to avoid installing in environments with strong winds.

1. Other environmental requirements

In addition to the above factors, other environmental factors such as ground flatness and air circulation need to be considered during the installation process of aluminum veneer. These factors will have a certain impact on the installation effect of aluminum veneer, so it is necessary to evaluate and handle them before installation.

The installation environment requirements for aluminum veneer are very strict, and multiple factors need to be considered to ensure its normal use. Consumers should choose aluminum veneer according to their actual usage needs and pay attention to the characteristics of the material and structural limitations during installation to ensure that the construction effect meets the requirements. Attention should also be paid to the impact of environmental factors during design and installation to improve the service life and safety of aluminum veneer.

Customer service QQ

Customer service QQ