Industry information

Company News

- The mystery of the "honeycomb" of aluminum honeycomb panel: the secret behind its lightness!

- Aluminum veneer: the fashionable outerwear of modern architecture

- Honeycomb aluminum plate: a perfect fusion of lightness and sturdiness

- The magnificent transformation of aluminum veneer: from ordinary to extraordinary

- The charm of honeycomb aluminum plate: light as a feather, indestructible

Industry dynamics

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Exquisite craftsmanship creates suspended ceiling roll coated aluminum veneer panels

- Comparative analysis of aluminum veneer and aluminum-plastic panel

- Honeycomb aluminum plate: the industrial revolution secret behind lightweight structures

Frequently asked questions

- What are the main uses of aluminum veneer?

- What is the market demand for aluminum veneer?

- What is the future development trend of aluminum veneer?

- How to increase the market demand for aluminum veneer?

- What will be the future development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

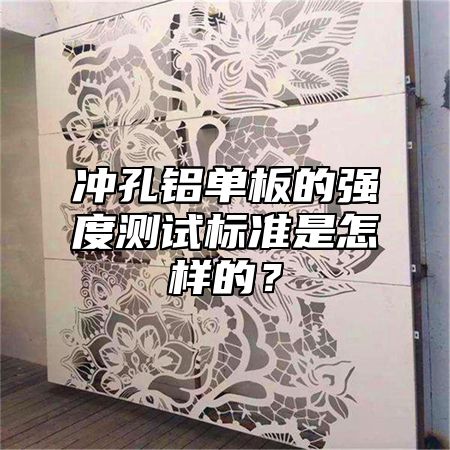

What is the strength testing standard for punched aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 22:54:38

- Click:0

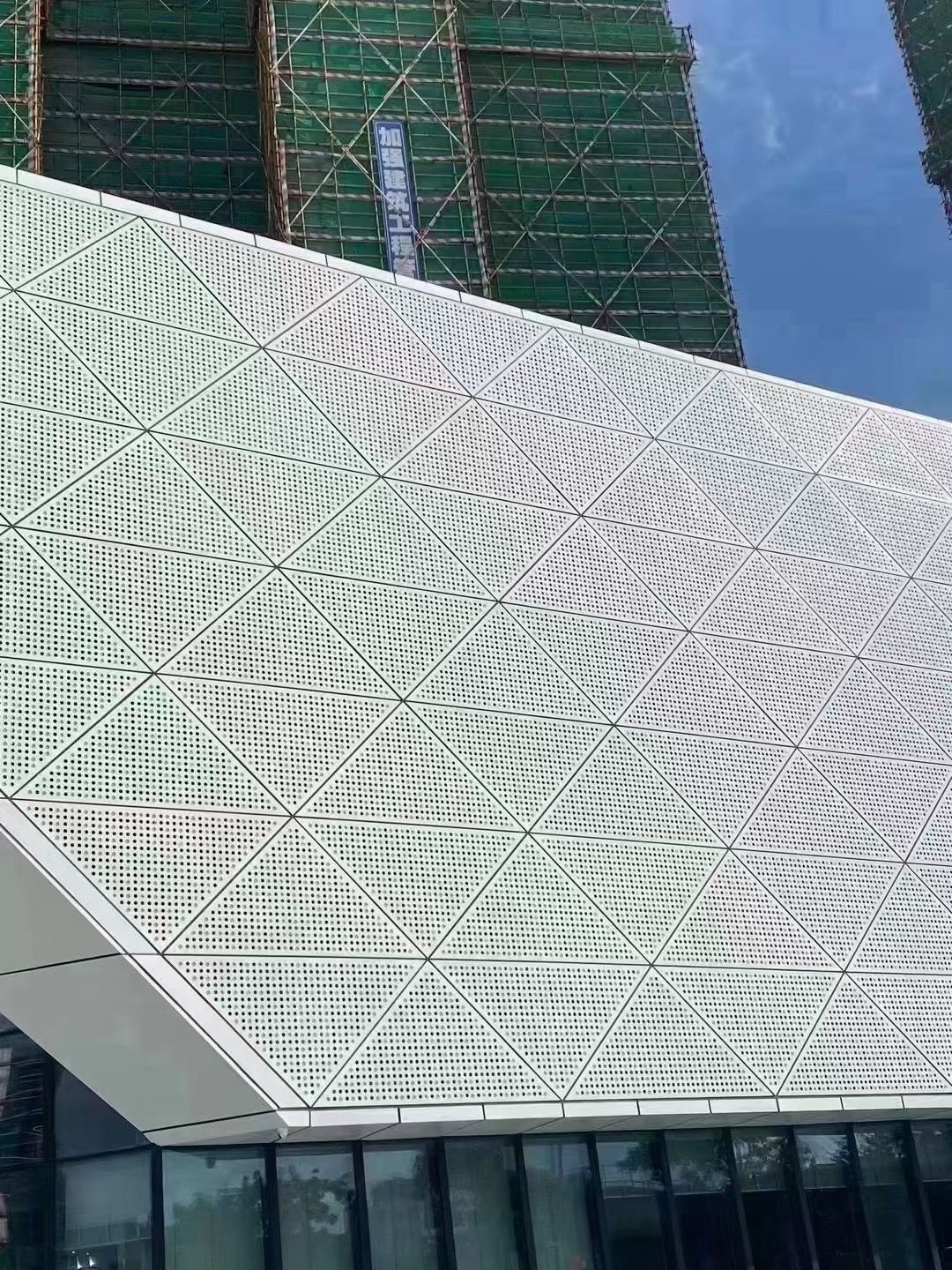

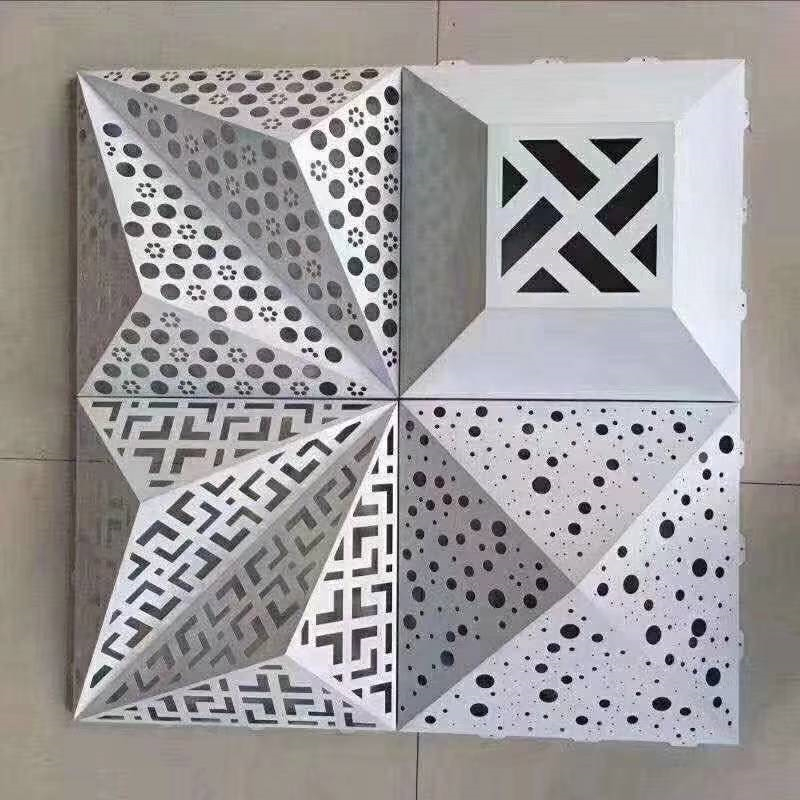

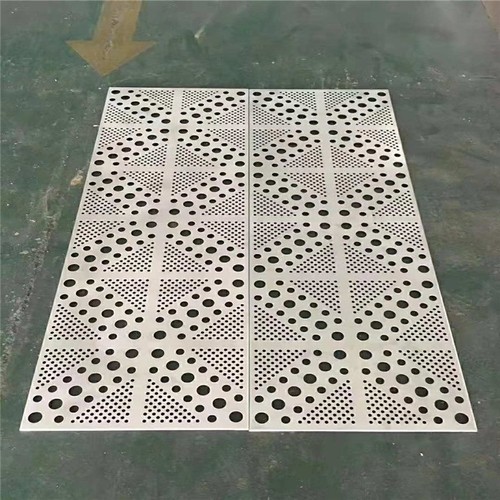

Punched aluminum veneer, as a widely used material in the fields of architectural decoration, advertising billboards, curtain walls, etc., its strength testing is one of the important means to ensure its quality and safety. The strength testing standards for punched aluminum veneer will be introduced from the following aspects.

1. Strength testing method for punched aluminum veneer

The strength testing methods for punched aluminum veneer mainly include tensile test, compression test, bending test, etc. Tensile test is a commonly used testing method that can test the tensile strength and elongation of materials under tensile force; Compression testing can test the compressive strength and deformation ability of materials under pressure; Bending test can test the bending strength and load-bearing capacity of materials under bending action.

1. Strength testing standard for punched aluminum veneer

At present, the internationally recognized strength testing standards for punched aluminum veneer mainly include the following:

(1) ISO 9001: This is a quality management system standard used to standardize the production and service processes of enterprises, ensuring the quality and safety of products.

(2) ISO 14001: This is an environmental management system standard used to standardize the environmental protection measures of enterprises and reduce their impact on the environment.

(3) ASTM B221: This is a standard for aluminum alloy sheets developed by the American Society for Testing and Materials, which includes requirements for tensile, compressive, bending, and other performance testing of punched aluminum veneers.

(4) GB/T 31948-2015: This is a Chinese national standard for aluminum alloy sheets, which also includes performance testing requirements for punched aluminum veneers such as tensile, compressive, and bending tests.

(5) EN 10216: This is a European standard for aluminum alloy sheets, which also includes performance testing requirements for punched aluminum veneers such as tension, compression, and bending.

The strength testing of punched aluminum veneer is one of the important means to ensure its quality and safety. By adopting appropriate testing methods and meeting standard testing requirements, the strength of punched aluminum veneer can be comprehensively evaluated, providing reliable data support for design and application.

Customer service QQ

Customer service QQ