Industry information

Company News

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock

- Aluminum veneer: the "silver warrior" of modern architecture

- Aluminum Curtain Feast: A New Chapter in Modern Architectural Aesthetics

- Aluminum honeycomb panel: the technological charm behind its lightweight design

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Understanding the entire process of indoor painted aluminum veneer from material selection to installation

- Application and effect display of brushed aluminum veneer in architectural decoration

- Advantages and market prospects of aluminum veneer

- What are the characteristics of the surface treatment process for punched aluminum veneer?

- Aluminum curtain wall: the "fashionable coat" of modern architecture

Frequently asked questions

- What are the characteristics of aluminum veneer?

- How long is the service life of aluminum veneer?

- What are the main uses of aluminum veneer?

- What will be the future development trend of aluminum veneer?

- What is the difference between aluminum veneer and aluminum-plastic panel?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

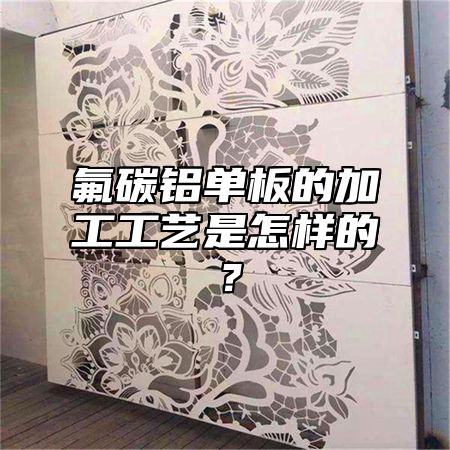

What is the processing technology for fluorocarbon aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-16 23:26:52

- Click:0

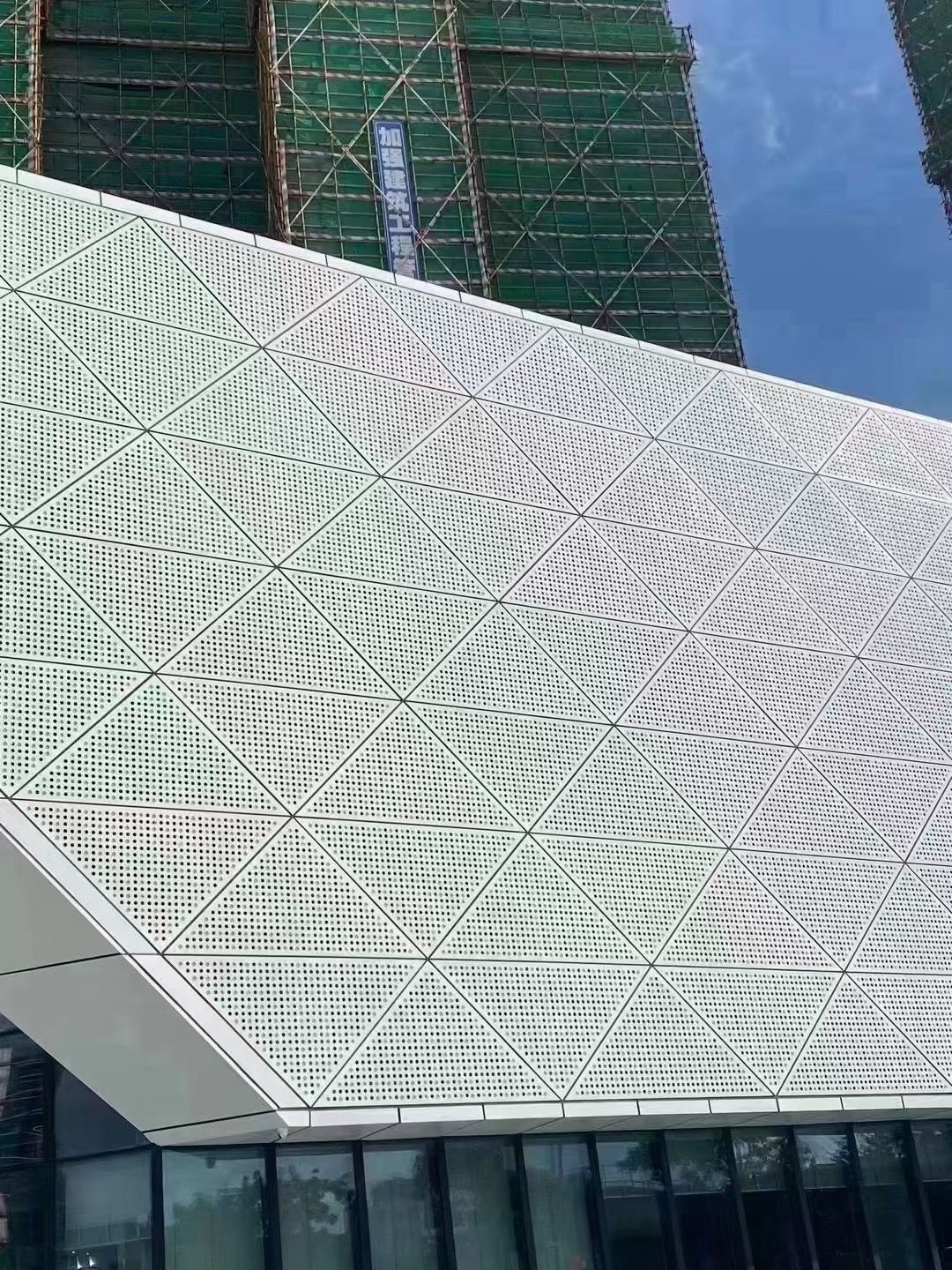

Fluorocarbon aluminum veneer is a widely used material in fields such as architectural decoration, advertising billboards, curtain walls, etc. Its processing technology is crucial for ensuring product quality and aesthetics. The following will provide a detailed introduction to the processing technology of fluorocarbon aluminum veneer.

1. Raw material preparation

The processing of fluorocarbon aluminum veneer requires the use of raw materials such as aluminum and fluorocarbon coatings. Before processing, strict inspection and screening of raw materials are required to ensure that their quality meets the requirements. It is also necessary to prepare relevant equipment and tools, such as cutting machines, bending machines, slotting machines, etc.

1. Cutting and processing

The shape and size of fluorocarbon aluminum veneer are generally customized according to customer needs, so cutting and processing are required. Cutting and processing can be carried out using CNC cutting machines or manual cutting machines. During the cutting process, it is necessary to control the cutting speed and angle to avoid problems such as burrs or cracks.

1. Bending processing

Fluorocarbon aluminum veneer usually requires bending processing to form the desired shape and structure. Bending processing can be carried out using a bending machine or by manual bending. During the bending process, attention should be paid to controlling the bending angle and force to avoid deformation or damage.

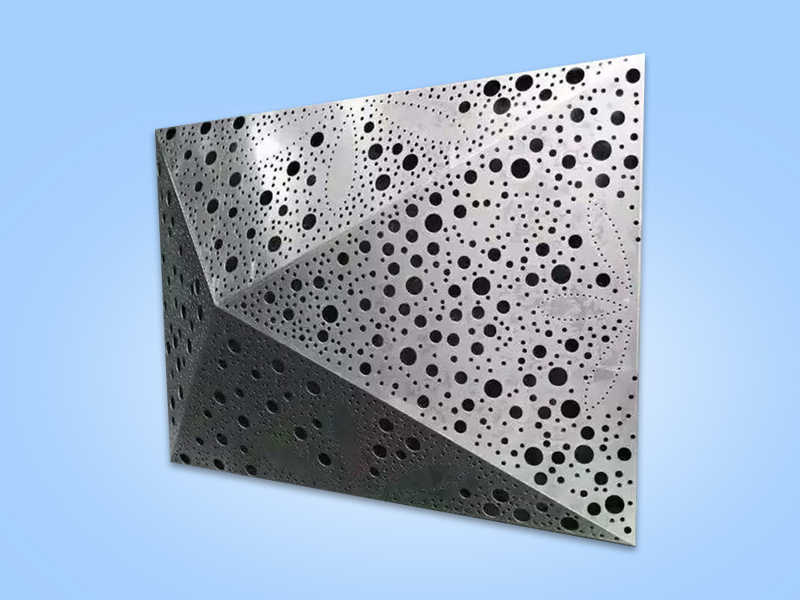

1. Punching processing

Fluorocarbon aluminum veneer usually requires punching processing to meet specific installation requirements. Punching processing can be carried out using punching machines or laser punching machines. During the punching process, attention should be paid to controlling the punching position and size to avoid deviation or damage.

1. Slotting processing

Fluorocarbon aluminum veneer usually requires slotting processing to meet specific installation requirements. Slotting processing can be done using slotting machines or manually slotting. During the slotting process, attention should be paid to controlling the depth and width of the slotting to avoid deformation or damage.

The processing technology of fluorocarbon aluminum veneer includes multiple stages such as raw material preparation, cutting, bending, punching, and slotting. These links require strict control of quality and technical requirements to ensure the stability of product quality and performance. In practical applications, consumers should choose products produced by legitimate manufacturers and follow the instructions and maintenance recommendations provided by the manufacturers to ensure the service life and aesthetics of fluorocarbon aluminum veneer.

Customer service QQ

Customer service QQ